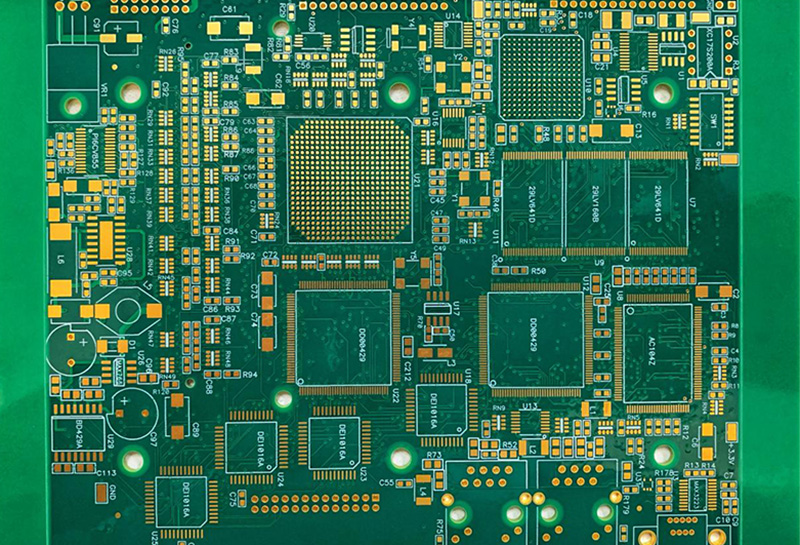

| Layers | 10 layers |

| Board thickness | 2.4MM |

| Material | FR4 tg170 |

| Copper thickness | 1/1/1/1/1/1/1/1/1/1 OZ(35um) |

| Surface Finish | ENIG Au Thickness 0.05um; Ni Thickness 3um |

| Min Hole(mm) | 0.203mm filled with resin |

| Min Line Width(mm) | 0.1mm/4mil |

| Min Line Space(mm) | 0.1mm/4mil |

| Solder Mask | Green |

| Legend Color | White |

| Mechanical processing | V-scoring, CNC Milling(routing) |

| Packing | Anti-static bag |

| E-test | Flying probe or Fixture |

| Acceptance standard | IPC-A-600H Class 2 |

| Application | Automotive electronics |

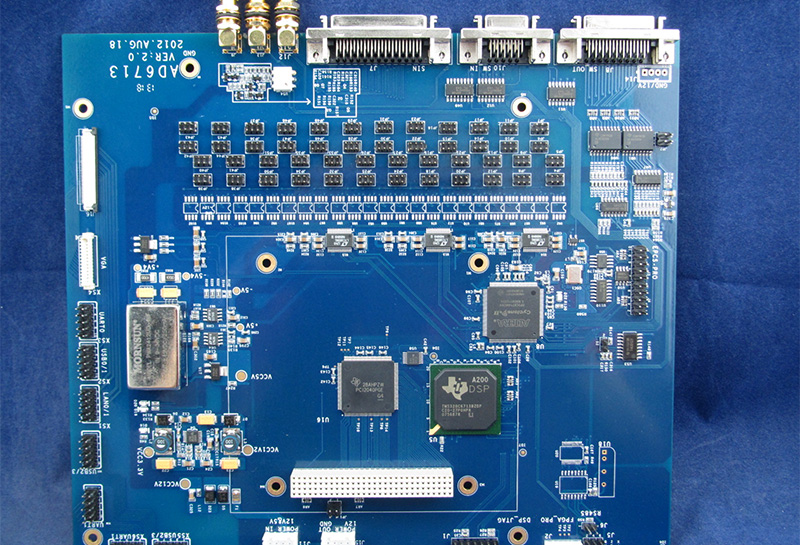

Through hole via It goes through the entire PCB, from the surface layer to the bottom layer, and is called a via. At this point, they connect all layers of the printed circuit board. However, vias take up more space and reduce component space. Blind via Blind vias simply connect the outer layer to the inner layer of the PCB. No need to drill the entire PCB. Buried via Buried vias are used to connect the inner layers of the PCB. Buried vias are not visible from the outside of the PCB. Micro via Micro vias are the smallest via size less than 6 mils. You need to use laser drilling to form micro vias. So basically, microvias are used for HDI boards. This is because of its size. Since you need component density and cannot waste space in an HDI PCB, it is wise to replace other common vias with microvias. Additionally, microvias do not suffer from thermal expansion issues (CTE) because of their shorter barrels. Stackup HDI PCB stack-up is a layer-by-layer organization. The number of layers or stacks can be determined as required. However, this could be 8 layers to 40 layers or more. But the exact number of layers depends on the density of the traces. Multilayer stacking can help you reduce PCB size. It also reduces manufacturing costs. By the way, to determine the number of layers on an HDI PCB, you need to determine the trace size and the nets on each layer. After identifying them, you can calculate the layer stackup required for your HDI board. Tips to design HDI PCB 1. Precise component selection. HDI boards require high pin count SMDs and BGAs smaller than 0.65mm. You need to choose them wisely as they affect via type, trace width and HDI PCB stack-up. 2. You need to use microvias on the HDI board. This will allow you to get double the space of a via or other. 3. Materials that are both effective and efficient must be used. It is critical to the manufacturability of the product. 4. To get a flat PCB surface, you should fill the via holes. 5. Try to choose materials with the same CTE rate for all layers. 6. Pay close attention to thermal management. Make sure you properly design and organize the layers that can properly dissipate excess heat. About:

Through hole via It goes through the entire PCB, from the surface layer to the bottom layer, and is called a via. At this point, they connect all layers of the printed circuit board. However, vias take up more space and reduce component space. Blind via Blind vias simply connect the outer layer to the inner layer of the PCB. No need to drill the entire PCB. Buried via Buried vias are used to connect the inner layers of the PCB. Buried vias are not visible from the outside of the PCB. Micro via Micro vias are the smallest via size less than 6 mils. You need to use laser drilling to form micro vias. So basically, microvias are used for HDI boards. This is because of its size. Since you need component density and cannot waste space in an HDI PCB, it is wise to replace other common vias with microvias. Additionally, microvias do not suffer from thermal expansion issues (CTE) because of their shorter barrels. Stackup HDI PCB stack-up is a layer-by-layer organization. The number of layers or stacks can be determined as required. However, this could be 8 layers to 40 layers or more. But the exact number of layers depends on the density of the traces. Multilayer stacking can help you reduce PCB size. It also reduces manufacturing costs. By the way, to determine the number of layers on an HDI PCB, you need to determine the trace size and the nets on each layer. After identifying them, you can calculate the layer stackup required for your HDI board. Tips to design HDI PCB 1. Precise component selection. HDI boards require high pin count SMDs and BGAs smaller than 0.65mm. You need to choose them wisely as they affect via type, trace width and HDI PCB stack-up. 2. You need to use microvias on the HDI board. This will allow you to get double the space of a via or other. 3. Materials that are both effective and efficient must be used. It is critical to the manufacturability of the product. 4. To get a flat PCB surface, you should fill the via holes. 5. Try to choose materials with the same CTE rate for all layers. 6. Pay close attention to thermal management. Make sure you properly design and organize the layers that can properly dissipate excess heat. About: Located in Shenzhen, ANKE PCB is a professional PCB production service provider with more than 10 years of experience in the electronics manufacturing industry. We've manufactured printed circuit boards and assembly service over 80 countries around the world. Our customer satisfaction rate is around 99%, and we take pride in providing the best service around.

We specialize in providing companies with full-range and high-quality PCB fabrication, PCB assembly and components sourcing services of prototype, small/medium/high volume products on the basis of 2,000 square meters and skilled employees over 400. We are dedicated to providing a complete electronic service that will help PCB designers bring their projects to market on time and on budget.

What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.