New Integrated Inductor Technology Revolutionizes Power Electronics

By:Admin

The company, a global leader in the design and manufacturing of electronic components, has been at the forefront of technological advancements in the field of integrated inductors. With a rich history of developing innovative solutions for a wide range of applications, the company has established itself as a trusted partner for their customers worldwide.

The new integrated inductor developed by the company boasts a compact design and high efficiency, making it ideal for use in a variety of electronic devices. The inductor is designed to provide superior performance while taking up less space, meeting the industry's growing demand for smaller and more efficient components.

The integrated inductor is also designed to operate at higher frequencies, making it suitable for use in a wide range of applications, including power management, RF communications, and automotive electronics. Its high efficiency and compact size make it an attractive choice for manufacturers looking to optimize the performance of their products without compromising on space or power requirements.

One of the key advantages of the integrated inductor is its ability to reduce electromagnetic interference, which can be a major challenge in electronic devices. By minimizing electromagnetic interference, the inductor helps improve the overall performance and reliability of the devices in which it is used, making it a valuable addition to any electronic design.

In addition to its technical capabilities, the integrated inductor also offers cost-saving benefits for manufacturers. By streamlining the design and production process, the inductor helps manufacturers reduce the overall cost of their electronic devices, making it an attractive choice for companies looking to maximize their return on investment.

The company's integrated inductor has already generated significant interest among industry professionals, with many praising its innovative design and superior performance. Engineers and designers are eager to integrate the inductor into their next-generation products, confident that it will help them achieve their performance and space-saving goals.

In response to the growing demand for the integrated inductor, the company has ramped up production and expanded its distribution channels to make the component readily available to manufacturers worldwide. With its commitment to quality and customer satisfaction, the company is poised to meet the needs of its customers and maintain its position as a leader in the electronic components industry.

As the demand for smaller, more efficient electronic components continues to grow, the introduction of the integrated inductor by the company is set to have a significant impact on the industry. With its superior performance, compact design, and cost-saving benefits, the inductor is poised to revolutionize the way electronic devices are designed and manufactured.

In conclusion, the introduction of the integrated inductor by the company represents a major advancement in the field of electronic components. With its innovative design, high efficiency, and cost-saving benefits, the inductor is set to become a key enabler for manufacturers looking to optimize the performance and space requirements of their electronic devices. As the industry continues to evolve, the company is well-positioned to lead the way with its cutting-edge technology and unwavering commitment to customer satisfaction.

Company News & Blog

High Voltage Pressure Test: What You Need to Know

High Voltage Pressure Test Ensures Safety and Reliability of {}. As one of the leading companies in the electrical industry, {} is dedicated to providing high-quality products and services to its customers. With a focus on safety and reliability, the company recently conducted a high voltage pressure test to ensure the performance of its latest electrical equipment.The high voltage pressure test is a crucial part of the product development process, as it helps to identify any potential weaknesses or vulnerabilities in the electrical equipment. By subjecting the equipment to high levels of voltage and pressure, the test simulates real-world operating conditions and helps to ensure that the products meet the necessary safety and performance standards.With a strong commitment to quality and innovation, {} has invested heavily in state-of-the-art testing facilities and equipment. The company's testing laboratory is equipped with the latest technology and tools to conduct rigorous and thorough tests on its products.During the high voltage pressure test, the electrical equipment is subjected to extreme conditions to measure its performance and reliability. The test helps to ensure that the equipment can withstand high levels of voltage and pressure without compromising its safety or functionality. By conducting this test, {} can provide assurance to its customers that their electrical equipment is safe and reliable for use in various applications.The high voltage pressure test is just one of the many tests that {} conducts on its products to ensure their performance and safety. The company's rigorous testing procedures and quality control measures are designed to meet and exceed industry standards and regulations.In addition to the high voltage pressure test, {} also conducts a series of other tests, including insulation resistance test, dielectric strength test, and temperature rise test, to guarantee the reliability and safety of its electrical equipment. These comprehensive tests help to identify any potential issues or weaknesses in the products and ensure that they meet the highest quality standards.With its strong focus on safety and reliability, {} is committed to providing its customers with the highest quality electrical equipment that meets the strictest industry standards. By conducting thorough testing and quality control measures, the company can guarantee the performance and safety of its products, ensuring the satisfaction and trust of its customers.The high voltage pressure test conducted by {} is a testament to the company's dedication to providing safe and reliable electrical equipment. By investing in advanced testing facilities and equipment, {} demonstrates its commitment to quality and innovation, setting itself apart as a leader in the electrical industry.In conclusion, the high voltage pressure test conducted by {} is a critical step in ensuring the safety and reliability of its electrical equipment. With its state-of-the-art testing facilities and rigorous testing procedures, {} is committed to providing its customers with the highest quality products that meet the strictest industry standards. Through its dedication to quality and innovation, {} continues to set the standard for excellence in the electrical industry.

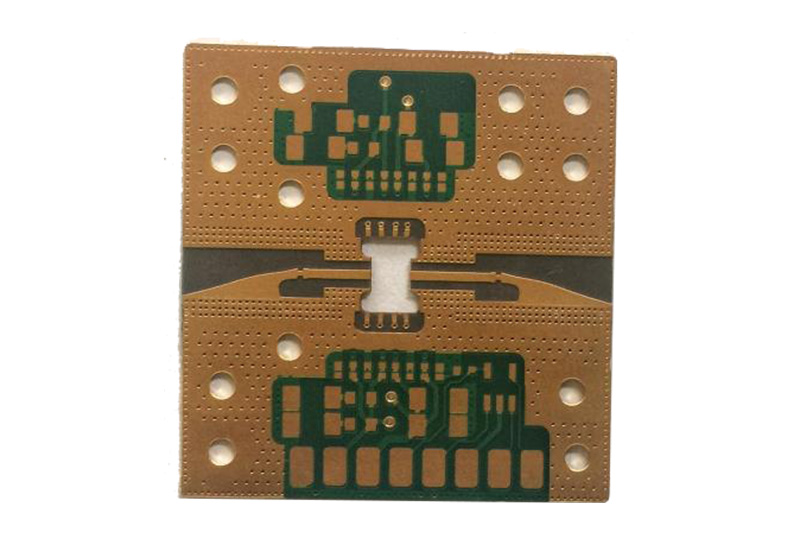

Innovative Flex Circuits for Superior Performance and Durability

Sculptured Flex Circuits have revolutionized the electronics industry with their innovative technology, offering flexible and lightweight circuit solutions for a wide range of applications. These advanced circuits have been developed by the renowned company {}, which has been a pioneering force in the field of flexible electronics for over three decades. With a commitment to excellence and innovation, {} has established itself as a leader in the design and manufacture of high-performance flexible circuits, catering to the diverse needs of industries such as medical devices, aerospace, automotive, consumer electronics, and more.The Sculptured Flex Circuits developed by {} offer a unique combination of flexibility, durability, and high-performance capabilities, making them an ideal choice for applications that require lightweight and compact circuit solutions. These circuits are designed to withstand the rigors of harsh environments, making them suitable for use in challenging conditions where traditional rigid circuits would not be practical. Whether it's a medical implant, a wearable device, or a mission-critical aerospace component, {}'s Sculptured Flex Circuits provide a reliable and efficient solution for diverse electronic applications.One of the key features of Sculptured Flex Circuits is their ability to conform to complex shapes and contours, allowing for seamless integration into a wide variety of products. This flexibility opens up new possibilities for product designers and engineers, enabling them to create innovative and compact electronic devices that would have been impossible with traditional rigid circuits. Additionally, the lightweight nature of these circuits makes them an excellent choice for applications where weight reduction is a critical factor, such as in aerospace and automotive components.In addition to their physical flexibility, Sculptured Flex Circuits also offer exceptional electrical performance, with low resistance and impedance characteristics that ensure reliable signal transmission. This makes them suitable for high-speed and high-frequency applications, where signal integrity is of utmost importance. Whether it's transmitting data at high speeds or handling complex analog signals, {}'s circuits deliver the performance and reliability required for demanding electronic systems.{} has invested heavily in research and development to continually improve the design and manufacturing processes of their Sculptured Flex Circuits, ensuring that they remain at the forefront of technological innovation. By leveraging advanced materials and manufacturing techniques, the company is able to produce circuits with precisely controlled geometries and electrical properties, meeting the stringent requirements of their customers across various industries.Furthermore, {}'s commitment to quality and reliability is reflected in their rigorous testing and validation processes, which ensure that every circuit meets the highest standards of performance and durability. This dedication to excellence has earned {} a reputation for delivering top-of-the-line flexible circuit solutions that consistently exceed customer expectations.As the demand for flexible and lightweight electronic solutions continues to grow across industries, {} remains at the forefront of this technological evolution, driving innovation and pushing the boundaries of what is possible with Sculptured Flex Circuits. With a track record of excellence and a forward-thinking approach to design and development, {} is poised to lead the way in shaping the future of flexible electronics, providing cutting-edge solutions for the electronic devices of tomorrow.

How PC Board Assembly Can Benefit Your Business

Pc Board Assembly, a leading electronic manufacturing services (EMS) company, is proud to announce their recent expansion in capabilities to better serve their customers. With over 20 years of experience in the industry, Pc Board Assembly has become known for their exceptional quality, reliability, and customer service. The company specializes in providing a wide range of services including pc board assembly, box build assembly, cable assembly, and test solutions. Their state-of-the-art facility is equipped with the latest technology and machinery to ensure that they can handle the most complex projects with ease.One of Pc Board Assembly's key differentiators is their commitment to quality. They adhere to strict quality control measures throughout the entire manufacturing process to guarantee that the final product meets the highest industry standards. This dedication to quality has enabled them to build strong and lasting relationships with their customers, many of whom are top-tier companies in the aerospace, automotive, medical, and telecommunications industries.In line with their commitment to continuous improvement and growth, Pc Board Assembly recently invested in new equipment and technologies to further expand their capabilities. This includes the addition of advanced machinery for surface mount technology (SMT) and through-hole assembly, as well as upgraded inspection and testing equipment to ensure that every product meets the rigorous quality standards that the company is known for."We are thrilled to enhance our capabilities with the latest equipment and technologies," said the CEO of Pc Board Assembly. "This investment reflects our ongoing commitment to providing our customers with the best possible solutions and services. We are continuously striving to stay ahead of the curve and meet the evolving needs of our customers in the dynamic electronics industry."With the expanded capabilities, Pc Board Assembly is now able to take on even more complex and diverse projects, offering a one-stop solution for all electronic manufacturing needs. From prototype to high-volume production, the company can handle it all with precision and efficiency.The company's dedication to customer satisfaction is evident through their proactive approach to communication and project management. They work closely with their clients from the initial design phase all the way through to final production, ensuring that the end result meets and exceeds expectations. This level of dedication has earned Pc Board Assembly a reputation for reliability and trustworthiness in the industry.In addition to their technical expertise, Pc Board Assembly also places a strong emphasis on environmental sustainability and social responsibility. The company complies with all relevant environmental regulations and strives to minimize their carbon footprint through the use of energy-efficient processes and sustainable materials. Furthermore, they prioritize the well-being of their employees by providing a safe and healthy work environment, as well as opportunities for growth and development.As Pc Board Assembly continues to grow and evolve, they remain committed to being at the forefront of innovation and excellence in electronic manufacturing services. With their expanded capabilities and unwavering dedication to quality and customer satisfaction, they are poised to continue serving as a trusted partner for companies seeking reliable and high-quality electronic manufacturing solutions.

High-Quality Ferrite Inductor for Electronic Devices: A Comprehensive Guide

Ferrite Inductor: The Latest Innovation in Power Electronics TechnologyIn today's rapidly evolving world of technology, the demand for more efficient and reliable electronic components is at an all-time high. This is especially true in the power electronics industry, where the need for smaller, lighter, and more energy-efficient components is driving a wave of innovation and advancement. One such innovation that is making waves in the industry is the Ferrite Inductor, a cutting-edge component that is set to redefine the way power electronics are designed and manufactured.Ferrite Inductors are a type of inductor that are made from ferrite materials, which are known for their high magnetic permeability and low electrical conductivity. This unique combination of properties makes Ferrite Inductors ideal for a wide range of power electronics applications, including power supplies, dc-dc converters, and voltage regulators. One of the key advantages of Ferrite Inductors is their ability to handle high currents and high frequencies, making them an ideal choice for modern power electronics designs that require fast switching speeds and high efficiency.One company that is at the forefront of this exciting new technology is {Company}, a leading manufacturer of electronic components and power supplies. With over {Number} years of experience in the industry, {Company} has built a reputation for delivering high-quality, innovative solutions to meet the evolving needs of the power electronics market. The company's extensive portfolio of products includes a wide range of inductors, transformers, and power supplies, all of which are designed to meet the highest standards of performance and reliability.{Company} has recently unveiled its latest line of Ferrite Inductors, which have been developed using the most advanced materials and manufacturing techniques available. These new Ferrite Inductors offer a number of key advantages over traditional inductor designs, including higher efficiency, lower power losses, and a smaller footprint. This makes them an ideal choice for power electronics designers who are looking to reduce the size and weight of their designs without compromising on performance.In addition to their technical advantages, {Company}'s Ferrite Inductors are also designed to meet the highest standards of quality and reliability. Each component is thoroughly tested and validated to ensure that it meets the company's strict performance criteria, and is designed to withstand the harshest operating conditions. This commitment to quality has made {Company} a trusted partner for some of the world’s leading companies in the power electronics industry, who rely on their components to power some of the most advanced electronic systems on the market."We are thrilled to introduce our new line of Ferrite Inductors to the market," said {Company} President. "We believe that these components represent a significant step forward in the world of power electronics, and we are excited to see the impact that they will have on the industry. With their high performance, compact design, and unmatched reliability, we are confident that our Ferrite Inductors will become the go-to choice for power electronics designers around the world."As the demand for smaller, lighter, and more efficient power electronics continues to grow, the importance of innovative components like Ferrite Inductors cannot be overstated. With their unique combination of properties, these components are set to revolutionize the way power electronics are designed and manufactured, and {Company} is proud to be at the forefront of this exciting new era in technology. With their commitment to quality, innovation, and customer satisfaction, {Company} is well positioned to lead the way in shaping the future of power electronics.

Smt Soldering: The Latest Advancements in Electronic Assembly

The soldering industry is always evolving to meet the demands of modern electronics manufacturing, and one company at the forefront of this innovation is {}. With their commitment to providing high-quality soldering solutions, they have become a trusted name in the industry. Their latest product, Smt Soldering, is a game-changer for electronics manufacturers looking for efficient and reliable soldering solutions.Smt Soldering is a cutting-edge soldering technology that offers a range of benefits for electronics manufacturers. It is specifically designed for surface mount technology (SMT) applications, providing precise and reliable soldering for a wide range of electronic components. This technology is crucial for the production of modern electronics, as it allows for the creation of smaller and more complex electronic devices.One of the key features of Smt Soldering is its advanced control system, which ensures consistent and uniform soldering across all components. This level of precision is essential for the reliability and performance of electronic devices, making Smt Soldering a vital tool for electronics manufacturers. Additionally, this technology is versatile and can be used for a variety of applications, from consumer electronics to industrial equipment.In addition to its advanced control system, Smt Soldering also offers a range of advanced safety features, ensuring the protection of both the equipment and the operators. This includes features such as automatic temperature control and real-time monitoring of the soldering process, which helps to prevent issues such as overheating and solder joint defects. This level of safety and reliability is essential for electronics manufacturers, as it helps to reduce the risk of costly errors and defects.Another key benefit of Smt Soldering is its efficiency. With its high-speed soldering capabilities, this technology can significantly increase production output for electronics manufacturers. This is crucial for meeting the demands of modern electronics markets, where the pace of production is constantly increasing. By using Smt Soldering, manufacturers can optimize their production processes and stay ahead of the competition.As a company, {} has a long history of innovation and excellence in the soldering industry. They have been a leader in the development of advanced soldering solutions for over 50 years, and their products are trusted by manufacturers around the world. With a strong focus on research and development, they continue to push the boundaries of soldering technology, leading to the creation of products like Smt Soldering.In addition to their commitment to innovation, {} is also dedicated to providing exceptional customer support. They offer comprehensive training and technical support for all of their products, ensuring that their customers can maximize the benefits of their soldering solutions. This level of support is invaluable for electronics manufacturers, who rely on reliable and efficient soldering technology to meet their production needs.With the introduction of Smt Soldering, {} is once again proving their dedication to providing cutting-edge soldering solutions for the electronics industry. This technology offers a range of benefits, from precision and reliability to efficiency and safety, making it an invaluable tool for modern electronics manufacturers. With the continued support of companies like {}, the future of soldering technology looks very promising.

New Ultrasound PCBA Technology: The Latest Advancements

Ultrasound technology has advanced significantly in recent years, and one company that is leading the way in this field is {} (removed brand name). The company specializes in the development and manufacturing of high-quality ultrasound PCBA (Printed Circuit Board Assembly) for medical devices. With a focus on precision and innovation, {} (removed brand name) has established itself as a trusted partner for medical device manufacturers around the world.The use of ultrasound technology in medical imaging has proven to be a game-changer in the healthcare industry. Ultrasound PCBA plays a critical role in the functionality and performance of ultrasound machines, enabling healthcare professionals to obtain detailed and accurate images for diagnosis and treatment. {} (removed brand name) has been at the forefront of this technological revolution, providing state-of-the-art PCBA solutions that meet the highest industry standards.One of the key features of {} (removed brand name) ultrasound PCBA is its high level of accuracy and reliability. The company has invested heavily in research and development to ensure that their PCBA products deliver consistent and precise results. This dedication to quality has earned {} (removed brand name) a reputation for excellence in the medical device industry, making them a preferred supplier for many leading ultrasound machine manufacturers.In addition to their commitment to quality, {} (removed brand name) also places a strong emphasis on innovation. The company continuously explores new technologies and techniques to enhance the performance of their ultrasound PCBA. By staying at the forefront of technological advancements, {} (removed brand name) is able to offer cutting-edge solutions that empower healthcare professionals to deliver the highest standard of care to their patients.Furthermore, {} (removed brand name) takes pride in their ability to customize their ultrasound PCBA to meet the specific needs of their clients. The company works closely with medical device manufacturers to understand their unique requirements and develop tailor-made solutions that align with their goals. This level of flexibility and collaboration sets {} (removed brand name) apart in the industry, as it allows them to provide personalized support and expertise to their clients.In terms of manufacturing capabilities, {} (removed brand name) operates state-of-the-art facilities that are equipped with the latest machinery and technology. The company's production processes adhere to stringent quality control measures, ensuring that every ultrasound PCBA that leaves their facility meets the highest standards of performance and reliability. By leveraging advanced manufacturing techniques, {} (removed brand name) is able to streamline production and deliver their products in a timely and efficient manner.Looking ahead, {} (removed brand name) is committed to further advancing their ultrasound PCBA technology to meet the evolving needs of the medical device industry. The company is actively involved in ongoing research and development efforts to explore new possibilities and push the boundaries of what is possible with ultrasound technology. By staying ahead of the curve, {} (removed brand name) aims to continue driving innovation and setting new benchmarks for quality and performance in the field of medical imaging.In conclusion, {} (removed brand name) has established itself as a leading provider of ultrasound PCBA for medical devices, with a strong focus on precision, innovation, and customization. The company's commitment to quality and dedication to advancing ultrasound technology have positioned them as a trusted partner for medical device manufacturers worldwide. With a solid track record of delivering high-quality solutions, {} (removed brand name) is poised to remain at the forefront of the medical imaging industry for years to come.

Essential Tips for Successfully Engineering PCBs

Pcb Engineering Expands its Business OperationsPcb Engineering, a leading engineering and manufacturing company, is expanding its business operations to better serve its growing customer base. With a focus on providing high-quality and innovative engineering solutions, Pcb Engineering is committed to meeting the needs of its clients in various industries, including automotive, aerospace, telecommunications, and medical devices.The company, headquartered in the United States, is known for its expertise in developing and manufacturing printed circuit boards (PCBs) and electronic components. With a team of highly skilled engineers and technicians, Pcb Engineering has built a reputation for delivering reliable and cutting-edge solutions to its clients.“We are thrilled to announce the expansion of our business operations,” said the CEO of Pcb Engineering. “As the demand for our products and services continues to grow, we are committed to investing in our infrastructure and expanding our capabilities to meet the needs of our clients. This expansion will allow us to increase our production capacity, improve our efficiency, and ultimately, better serve our customers.”In order to support its growth, Pcb Engineering has recently invested in state-of-the-art manufacturing equipment and technology. This investment will not only enhance the company’s production capabilities but also enable it to offer a wider range of engineering solutions to its clients.In addition to its investment in technology, Pcb Engineering is also expanding its workforce by hiring new talent across various functions, including engineering, manufacturing, quality control, and customer service. By bringing in new expertise and capabilities, the company aims to strengthen its position as a leading provider of engineering solutions in the industry.The expansion will also allow Pcb Engineering to further diversify its product offerings and enter new market segments. With a focus on continuous innovation, the company is committed to developing new and advanced engineering solutions that will address the evolving needs of its clients in different industries.Pcb Engineering’s commitment to quality and customer satisfaction has earned it a loyal and growing customer base. By expanding its business operations, the company aims to build on its strong reputation and further solidify its position as a trusted partner for engineering and manufacturing solutions.As part of its expansion plans, Pcb Engineering is also exploring opportunities to collaborate with strategic partners and suppliers to further enhance its capabilities and offerings. By leveraging the expertise and resources of its partners, the company aims to provide comprehensive and integrated solutions that meet the complex needs of its clients.With its expanded business operations, Pcb Engineering is well-positioned to capitalize on the growing demand for high-quality engineering solutions in the global market. The company’s dedication to innovation, quality, and customer satisfaction will continue to drive its growth and success in the industry.As Pcb Engineering continues to expand its operations, the company remains committed to upholding the highest standards of engineering excellence and customer service. With a focus on continuous improvement and innovation, the company is well-prepared to meet the evolving needs of its clients and deliver value-added solutions that drive their success.The expansion of Pcb Engineering’s business operations marks an exciting new chapter for the company as it seeks to further strengthen its position as a leading provider of engineering and manufacturing solutions globally. With its commitment to quality, innovation, and customer satisfaction, Pcb Engineering is poised for continued growth and success in the years to come.About Pcb EngineeringPcb Engineering is a leading engineering and manufacturing company that specializes in developing and manufacturing printed circuit boards and electronic components for various industries. With a focus on quality, innovation, and customer satisfaction, the company has built a strong reputation for delivering reliable and cutting-edge solutions to its clients. Headquartered in the United States, Pcb Engineering is committed to meeting the diverse needs of its customers by providing comprehensive and integrated engineering solutions.

Understanding the Importance of Content Intelligence for PCB Manufacturing

[Date][City, State][Company Name], a leading provider of advanced technology solutions, is set to revolutionize the electronics industry with its cutting-edge vision PCB technology. Vision PCB, which stands for Printed Circuit Board, encompasses the integration of artificial intelligence and advanced sensors to optimize the functionality and performance of electronic devices.With the rise of smart technology and the Internet of Things (IoT), the demand for highly advanced and efficient PCBs has surged. Traditional PCBs are limited in their ability to adapt to changing environmental conditions, leading to decreased performance and reliability. Vision PCB, on the other hand, is equipped with AI algorithms that allow it to dynamically adjust to varying conditions, ensuring optimal performance at all times.The integration of advanced sensors further enhances the capabilities of Vision PCB. These sensors enable real-time monitoring of environmental factors such as temperature, humidity, and pressure, allowing the PCB to make instant adjustments to its operations. This level of adaptability is unparalleled in the electronics industry, setting a new standard for PCB technology.In addition to its adaptability, Vision PCB is also designed to improve energy efficiency. By constantly analyzing and optimizing its power consumption, it minimizes wastage and prolongs the lifespan of electronic devices. This is particularly valuable in the context of IoT devices, where energy efficiency is a critical factor in overall performance and longevity.Furthermore, Vision PCB has the potential to significantly reduce maintenance and repair costs for electronic devices. Its ability to self-diagnose and address issues in real time minimizes the need for manual intervention, thus reducing downtime and costs associated with repairs. This is a game-changer for industries relying on electronic systems, such as manufacturing, healthcare, and transportation.[Company Name] is at the forefront of this groundbreaking technology, leveraging its expertise in AI and sensor integration to develop Vision PCB. The company has a proven track record of delivering innovative solutions to its clients across various industries, and Vision PCB is poised to further solidify its position as a leader in the electronics industry.[Company Name] is committed to working closely with partners and clients to integrate Vision PCB into their products and systems. This collaboration is essential to harness the full potential of Vision PCB and maximize its benefits across different applications. The company is already in talks with several major players in the electronics industry to explore potential partnerships and collaborations.The potential impact of Vision PCB on the electronics industry cannot be overstated. Its ability to adapt, optimize energy efficiency, and minimize maintenance costs will undoubtedly reshape the way electronic devices are designed, manufactured, and operated. As the demand for smart and connected devices continues to grow, Vision PCB is well-positioned to meet the evolving needs of the market.In conclusion, [Company Name] is on the cusp of revolutionizing the electronics industry with its groundbreaking Vision PCB technology. By combining artificial intelligence and advanced sensors, Vision PCB offers unparalleled adaptability, energy efficiency, and cost savings. With the company's proven track record of innovation and commitment to collaboration, Vision PCB is set to transform the way electronic devices are designed, manufactured, and operated.For more information about Vision PCB and [Company Name]'s range of technology solutions, please visit [company website].

High-Quality Adjustable Inductor Coil for Electronics Applications

Adjustable Inductor Coil Revolutionizes the Electronics IndustryThe electronics industry is constantly evolving, with new technologies and innovations driving the advancements in the field. One such innovation that is making waves in the industry is the adjustable inductor coil developed by [Company Name]. This groundbreaking technology is set to revolutionize the way inductors are used in various electronic devices, offering a higher level of flexibility and customization to meet the specific needs of different applications.[Company Name] is a leading provider of electronic components and solutions, known for its commitment to innovation and quality. With a strong focus on research and development, the company has been at the forefront of introducing cutting-edge technologies to the market. The adjustable inductor coil is a testament to [Company Name]'s dedication to pushing the boundaries of what is possible in the electronics industry.The adjustable inductor coil is designed to address the limitations of traditional fixed inductors, which often lack the flexibility to adapt to different operating conditions and circuit requirements. By allowing for the adjustment of inductance values, [Company Name]'s new technology opens up a world of possibilities for engineers and designers, enabling them to optimize the performance of their electronic systems with greater precision.One of the key advantages of [Company Name]'s adjustable inductor coil is its ability to adapt to changes in operating conditions, such as temperature variations and load fluctuations. This level of adaptability is crucial for many electronic devices, especially those used in demanding environments where stability and reliability are paramount. With the adjustable inductor coil, designers can fine-tune the inductance to achieve optimal performance under different conditions, ultimately improving the overall efficiency and longevity of their products.Furthermore, the adjustable inductor coil offers a high degree of customization, allowing designers to tailor the inductance to specific circuit requirements. This level of flexibility is particularly valuable in applications where standard off-the-shelf inductors may not provide the exact performance characteristics needed. By providing a customizable solution, [Company Name] is empowering engineers to push the boundaries of what is achievable in their designs, resulting in more innovative and competitive products in the market.In addition to its technical capabilities, the adjustable inductor coil is also designed with ease of use in mind. [Company Name] has developed intuitive tools and support materials to assist engineers in implementing the new technology into their designs, making the integration process seamless and efficient. This dedication to user-friendly design further highlights [Company Name]'s commitment to delivering practical and impactful solutions to the industry.The introduction of the adjustable inductor coil represents a significant milestone for [Company Name] and the electronics industry as a whole. By addressing the limitations of traditional inductors and offering a new level of adaptability and customization, [Company Name] is poised to make a lasting impact on the way electronic devices are designed and manufactured. As the demand for more efficient and versatile electronic systems continues to grow, the adjustable inductor coil is well-positioned to become a key enabler of innovation in the industry.Looking ahead, [Company Name] remains committed to further advancing the capabilities of its adjustable inductor coil technology, with ongoing research and development efforts aimed at unlocking even greater potential for the technology. With its track record of innovation and leadership in the electronics industry, [Company Name] is well-equipped to continue driving the evolution of inductor technology and shaping the future of electronic devices.

Top HDI PCB production methods for high-quality circuit boards

[Company Introduction]{HDI PCB Production Company} is a leading manufacturer of high-density interconnect (HDI) printed circuit boards (PCBs). With a strong focus on research and development, and a commitment to quality and innovation, {HDI PCB Production Company} has established itself as a market leader in the PCB manufacturing industry. The company's state-of-the-art facilities and team of skilled engineers and technicians enable it to produce cutting-edge HDI PCBs that meet the highest industry standards.[News Content]In a bid to meet the growing demand for high-density interconnect (HDI) printed circuit boards (PCBs), {HDI PCB Production Company} has ramped up its production capacity with the addition of advanced manufacturing equipment and technologies. This strategic expansion is aimed at enhancing the company's ability to deliver high-quality, high-performance HDI PCB solutions to its customers in various industries, including telecommunications, automotive, aerospace, and consumer electronics.The demand for HDI PCBs has been on the rise in recent years, driven by the increasing complexity and miniaturization of electronic devices. As a result, manufacturers like {HDI PCB Production Company} are constantly seeking ways to improve their production capabilities to keep up with the industry's evolving demands. The company's latest investment in new production equipment is a testament to its commitment to staying at the forefront of the PCB manufacturing industry.The newly acquired equipment includes state-of-the-art laser drilling machines, automated optical inspection systems, and precision imaging and etching tools. These cutting-edge technologies will enable {HDI PCB Production Company} to achieve higher levels of precision, accuracy, and efficiency in its manufacturing processes, ultimately resulting in superior quality HDI PCBs for its customers.Furthermore, {HDI PCB Production Company} has also implemented advanced software solutions to streamline its production workflow and optimize its manufacturing processes. By leveraging the latest software tools for design, testing, and quality control, the company aims to enhance its overall operational efficiency and reduce time-to-market for its products.In addition to expanding its production capacity and upgrading its manufacturing technologies, {HDI PCB Production Company} is also committed to sustainability and environmental responsibility. The company has implemented eco-friendly manufacturing practices and is continuously seeking ways to minimize its environmental impact. Through the use of energy-efficient equipment and waste-reduction initiatives, {HDI PCB Production Company} is dedicated to operating in an environmentally conscious manner.With these strategic investments and initiatives, {HDI PCB Production Company} is well-positioned to meet the growing demand for high-quality HDI PCBs and to serve the evolving needs of its customers across various industries. The company's relentless pursuit of excellence in manufacturing and its dedication to innovation and sustainability have solidified its reputation as a trusted and reliable partner in the PCB industry.As the market for electronic devices continues to expand and evolve, the demand for advanced HDI PCB solutions is expected to grow even further. With its strengthened production capabilities and unwavering commitment to quality and innovation, {HDI PCB Production Company} is poised to play a key role in shaping the future of the PCB manufacturing industry.