Essential Guide to Understanding the Empty PCB Board

By:Admin

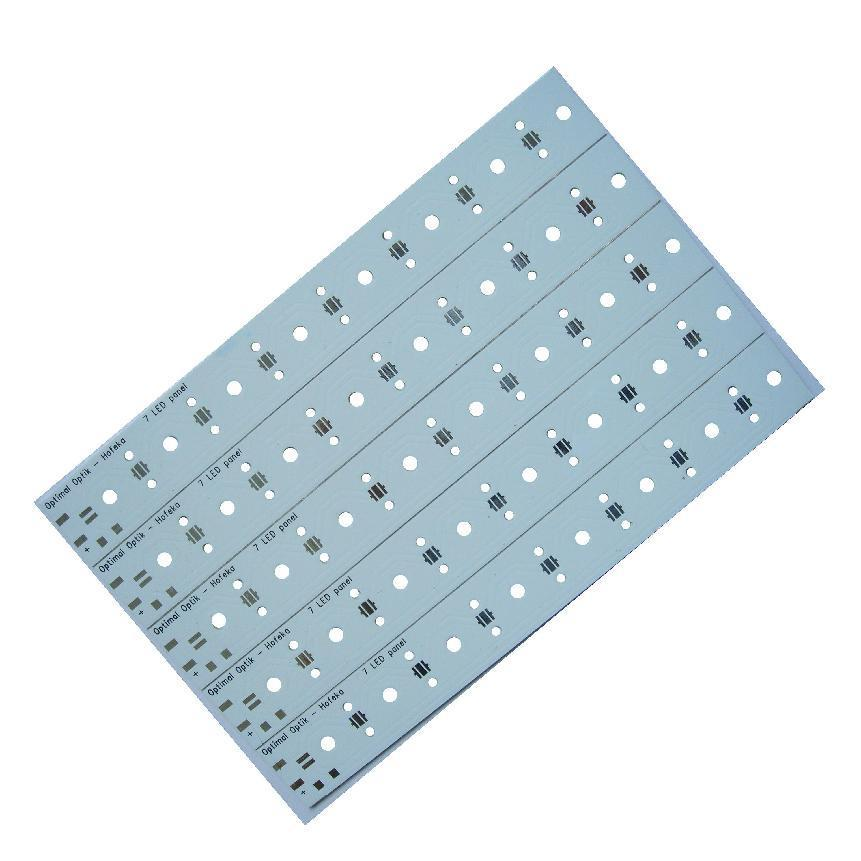

{Company} is known for its innovative approach to electronic components, and the introduction of these empty PCB boards is a testament to their commitment to providing quality products to their customers. The company specializes in the production of a wide range of electronic components, including PCB boards, connectors, and cables. With a focus on research and development, {Company} has built a strong reputation for producing high-quality and reliable electronic components.

The new line of empty PCB boards from {Company} offers a range of benefits for electronic manufacturers and hobbyists. These boards are designed to be easily customizable, allowing users to create unique designs tailored to their specific needs. The empty PCB boards also provide a cost-effective solution for manufacturers, as they can be easily integrated into existing electronic products.

In addition to their customizability and cost-effectiveness, the empty PCB boards from {Company} are also known for their high-quality construction. The company utilizes advanced production techniques and strict quality control measures to ensure that each PCB board meets the highest standards of performance and reliability.

Furthermore, the introduction of these empty PCB boards reflects {Company}'s commitment to sustainability. The company has implemented eco-friendly production practices and uses recyclable materials in the manufacturing of their products. By offering an option for reusable and customizable PCB boards, {Company} is providing a sustainable solution for electronic manufacturers and hobbyists.

{Company}'s empty PCB boards have already garnered significant interest from the electronic manufacturing industry. Many manufacturers are excited about the prospect of being able to create unique electronic products with the help of these customizable PCB boards. Additionally, hobbyists are also eager to take advantage of the versatility and cost-effectiveness offered by {Company}'s new line of products.

As the demand for customizable electronic components continues to grow, {Company} is well-positioned to become a leading provider of empty PCB boards. With their commitment to innovation, quality, and sustainability, the company is poised to set a new standard in the electronic manufacturing industry.

Overall, the introduction of empty PCB boards from {Company} represents a significant development in the electronic manufacturing industry. The customizable nature, cost-effectiveness, and high-quality construction of these boards make them an attractive option for manufacturers and hobbyists alike. With a strong reputation for producing reliable electronic components, {Company} is well-equipped to meet the growing demand for customizable and sustainable PCB boards.

Company News & Blog

The Future of Smart Manufacturing: The Impact of IoT Technology on Production

In today's fast-paced and ever-evolving world, the manufacturing industry is constantly looking for ways to improve production efficiency, reduce costs, and deliver superior quality products to meet the demands of the market. The emergence of Industry 4.0 and the Internet of Things (IoT) has revolutionized the way manufacturing companies operate, bringing about a new era of smart, connected, and automated production processes.With the integration of IoT in manufacturing, companies are able to gather and analyze real-time data from their production equipment, allowing for better decision-making, predictive maintenance, and overall optimization of the manufacturing process. This technology has the potential to transform traditional factories into smart factories, where machines, systems, and products communicate with each other to improve operational efficiency and drive innovation.One company that has been at the forefront of IoT manufacturing is {}. specializes in providing cutting-edge IoT solutions for manufacturers to help them optimize their production processes and achieve higher levels of productivity and quality. With a strong focus on innovation and customer satisfaction, {} has established itself as a leading provider of IoT manufacturing solutions, partnering with manufacturers across various industries to help them embrace the digital transformation of their operations.{}'s IoT manufacturing solutions are tailored to meet the specific needs of each customer, providing a seamless integration of IoT technologies into their existing production systems. By leveraging the power of IoT, manufacturers are able to monitor and control their production processes in real-time, identify potential issues before they escalate, and make informed decisions to improve overall efficiency and reduce downtime.One of the key features of {}'s IoT manufacturing solutions is the use of advanced sensors and connected devices to collect and transmit data from the factory floor to a centralized system. This real-time data can then be analyzed using sophisticated analytics tools to gain insights into production performance, equipment utilization, and quality control. By harnessing this wealth of information, manufacturers can proactively address production inefficiencies, optimize resource utilization, and continuously improve their processes to stay ahead of the competition.Furthermore, {}'s IoT manufacturing solutions enable manufacturers to implement predictive maintenance strategies, where equipment health and performance data are used to predict potential failures and schedule maintenance activities accordingly. This proactive approach to maintenance not only helps to prevent costly downtime but also extends the lifespan of equipment, reducing overall maintenance costs and improving the reliability of production systems.Another significant benefit of {}'s IoT manufacturing solutions is the ability to enable remote monitoring and control of production processes. With the use of connected devices and cloud-based platforms, manufacturers can access real-time production data from anywhere, allowing them to monitor and adjust their processes on the go. This level of flexibility and control is essential for manufacturers to adapt to changing market demands, address production issues promptly, and make data-driven decisions to optimize their operations.As manufacturers continue to embrace the digital transformation of their operations, {} remains committed to empowering them with the latest IoT manufacturing technologies and expertise. By collaborating closely with manufacturers, understanding their unique challenges, and delivering tailored IoT solutions, {} is driving the adoption of Industry 4.0 principles within the manufacturing industry, helping companies to unlock new levels of efficiency, productivity, and competitiveness.In conclusion, the integration of IoT in manufacturing has disrupted traditional production processes, paving the way for smart factories that are equipped with advanced technologies to drive operational excellence. With {}'s leading IoT manufacturing solutions, manufacturers are able to harness the power of real-time data, predictive analytics, and remote monitoring to transform their operations, achieve higher levels of efficiency, and stay ahead in today's highly competitive market. As the manufacturing industry continues to evolve, companies like {} will play a pivotal role in helping manufacturers navigate the complexities of digital transformation and realize the full potential of IoT in manufacturing.

Top Passive Resistors: What you need to know

Passive Resistor Company XYZ - A Leading Innovator in Electronic ComponentsPassive Resistor Company XYZ, based in [location], is a leading innovator in the field of electronic components. With a rich history spanning over 30 years, the company has established itself as a trusted provider of high-quality passive resistor products for a wide range of industries, including automotive, aerospace, telecommunications, and consumer electronics.The company's commitment to innovation and excellence has propelled it to the forefront of the electronic components industry. By leveraging cutting-edge technology and state-of-the-art manufacturing processes, Passive Resistor Company XYZ consistently delivers products that meet the highest standards of quality and performance.One of the key factors contributing to the company's success is its unwavering dedication to research and development. Passive Resistor Company XYZ invests heavily in R&D, continuously exploring new materials, designs, and manufacturing techniques to stay ahead of the curve. This relentless pursuit of innovation has led to the development of a diverse portfolio of passive resistor products that cater to the evolving needs of the market.Furthermore, the company's commitment to quality is evident in its rigorous testing and quality assurance processes. Before any product is released to the market, it undergoes thorough testing to ensure that it meets the stringent specifications and performance requirements set forth by Passive Resistor Company XYZ. This dedication to quality has earned the company a reputation for reliability and consistency, setting it apart from its competitors.In addition to its commitment to innovation and quality, Passive Resistor Company XYZ places a strong emphasis on customer satisfaction. The company's dedicated team of engineers and customer service professionals work closely with clients to understand their unique requirements and provide customized solutions that meet their specific needs. This customer-centric approach has cemented the company's position as a trusted partner for businesses seeking high-quality passive resistor products.The company's comprehensive product offering includes a wide range of passive resistor solutions, including film resistors, wirewound resistors, thick film resistors, and high voltage resistors. These products are designed to address the diverse needs of various applications, from precision instruments to heavy-duty industrial equipment.Passive Resistor Company XYZ's dedication to excellence has not gone unnoticed. The company has received numerous accolades and certifications for its outstanding performance and commitment to quality. It holds ISO 9001 certification, demonstrating its adherence to the highest standards of quality management.Looking ahead, Passive Resistor Company XYZ is poised for continued growth and success. With a strong focus on innovation and customer satisfaction, the company is well-positioned to capitalize on the expanding market for electronic components. As technology continues to advance and demand for reliable passive resistor products grows, Passive Resistor Company XYZ is committed to leading the way with cutting-edge solutions that meet the evolving needs of its customers.In conclusion, Passive Resistor Company XYZ has established itself as a leading innovator in the electronic components industry, with a strong commitment to quality, innovation, and customer satisfaction. With a rich history of success and a dedication to staying ahead of the curve, the company is well-equipped to meet the demands of a rapidly evolving market and continue its legacy of excellence in the years to come.

New Integrated Inductor Technology Revolutionizes Power Electronics

Integrated inductors are an essential component in many electronic devices, and the demand for smaller, more efficient inductors has been growing in recent years. This demand has been met by the innovative technology developed by a leading electronics company, which has introduced a cutting-edge integrated inductor that is set to revolutionize the industry.The company, a global leader in the design and manufacturing of electronic components, has been at the forefront of technological advancements in the field of integrated inductors. With a rich history of developing innovative solutions for a wide range of applications, the company has established itself as a trusted partner for their customers worldwide.The new integrated inductor developed by the company boasts a compact design and high efficiency, making it ideal for use in a variety of electronic devices. The inductor is designed to provide superior performance while taking up less space, meeting the industry's growing demand for smaller and more efficient components.The integrated inductor is also designed to operate at higher frequencies, making it suitable for use in a wide range of applications, including power management, RF communications, and automotive electronics. Its high efficiency and compact size make it an attractive choice for manufacturers looking to optimize the performance of their products without compromising on space or power requirements.One of the key advantages of the integrated inductor is its ability to reduce electromagnetic interference, which can be a major challenge in electronic devices. By minimizing electromagnetic interference, the inductor helps improve the overall performance and reliability of the devices in which it is used, making it a valuable addition to any electronic design.In addition to its technical capabilities, the integrated inductor also offers cost-saving benefits for manufacturers. By streamlining the design and production process, the inductor helps manufacturers reduce the overall cost of their electronic devices, making it an attractive choice for companies looking to maximize their return on investment.The company's integrated inductor has already generated significant interest among industry professionals, with many praising its innovative design and superior performance. Engineers and designers are eager to integrate the inductor into their next-generation products, confident that it will help them achieve their performance and space-saving goals.In response to the growing demand for the integrated inductor, the company has ramped up production and expanded its distribution channels to make the component readily available to manufacturers worldwide. With its commitment to quality and customer satisfaction, the company is poised to meet the needs of its customers and maintain its position as a leader in the electronic components industry.As the demand for smaller, more efficient electronic components continues to grow, the introduction of the integrated inductor by the company is set to have a significant impact on the industry. With its superior performance, compact design, and cost-saving benefits, the inductor is poised to revolutionize the way electronic devices are designed and manufactured.In conclusion, the introduction of the integrated inductor by the company represents a major advancement in the field of electronic components. With its innovative design, high efficiency, and cost-saving benefits, the inductor is set to become a key enabler for manufacturers looking to optimize the performance and space requirements of their electronic devices. As the industry continues to evolve, the company is well-positioned to lead the way with its cutting-edge technology and unwavering commitment to customer satisfaction.

High-Quality Printed Circuit Board Assembly Services - All You Need to Know

Printed Circuit Board Assembly (PCBA) is an essential part of electronic devices, and it plays a crucial role in the functionality of various electronic products. PCBA typically involves soldering various electronic components onto a printed circuit board, which is then used in devices such as smartphones, computers, and other electronic gadgets.{Company Name} is a leading manufacturer of PCBA, specializing in high-quality electronic assembly and manufacturing services. With a strong focus on innovation and technology, {Company Name} has built a reputation for delivering reliable and cost-effective PCBA solutions to a wide range of industries.Recently, {Company Name} announced the launch of its latest generation of PCBA, which features advanced technology and enhanced capabilities. The new PCBA is designed to meet the increasing demand for smaller, more powerful, and more energy-efficient electronics, offering customers a reliable and efficient solution for their electronic assembly needs.The new PCBA from {Company Name} incorporates the latest advancements in manufacturing technology, including state-of-the-art automated assembly equipment and advanced quality control processes. This allows {Company Name} to produce PCBA with higher precision and reliability, meeting the stringent quality standards required by the electronics industry.In addition to its advanced manufacturing capabilities, {Company Name} is committed to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing process, ensuring that its PCBA products are produced in a sustainable and environmentally responsible manner.With the launch of its latest generation of PCBA, {Company Name} aims to further solidify its position as a leading provider of electronic assembly solutions. The company's dedication to innovation and quality, combined with its commitment to sustainability, sets it apart as a trusted and reliable partner for businesses looking for high-quality PCBA solutions.{Company Name} is also focused on providing exceptional customer service, offering comprehensive technical support and personalized solutions to meet the unique needs of its clients. The company's team of experienced engineers and technicians are dedicated to delivering the highest level of service, ensuring that customers receive the best possible PCBA solutions for their specific requirements.As the demand for advanced electronic devices continues to grow, {Company Name} is well-positioned to meet the needs of the industry with its latest generation of PCBA. The company's commitment to innovation, quality, and sustainability, combined with its exceptional customer service, makes it a top choice for businesses seeking reliable and efficient electronic assembly solutions.In conclusion, {Company Name}'s latest generation of PCBA represents a significant advancement in electronic assembly technology, offering customers a reliable and efficient solution for their electronic manufacturing needs. With its dedication to innovation, quality, and sustainability, {Company Name} is poised to continue leading the industry in providing high-quality PCBA solutions to a wide range of industries.

How to Get a Custom Stencil Made for Your Project

Having A Stencil Made is an essential part of many businesses and industries. Whether you are a small business owner or a large corporation, having a custom stencil made can help you streamline your operations and create a consistent brand image. From manufacturing to marketing, stencils are used for a variety of purposes and can make a big impact on your business.At {}, we specialize in creating high-quality custom stencils for a wide range of applications. Our state-of-the-art manufacturing facility and skilled team of professionals allow us to produce stencils of all shapes and sizes with precision and accuracy. Whether you need a simple lettering stencil or a complex design, we have the capabilities to bring your vision to life.One of the biggest benefits of having a custom stencil made is the ability to efficiently mark products or packaging. This is especially important in industries such as manufacturing and logistics, where proper labeling and identification are crucial. A custom stencil allows you to apply the same marking consistently and quickly, saving time and reducing errors in the process. In addition, stencils can help you comply with industry regulations and standards, ensuring that your products are clearly and accurately labeled.In the world of marketing and advertising, stencils can also be a powerful tool for creating branded visuals and messaging. Whether you are a retailer looking to add a unique touch to your storefront or a marketing agency working on a large-scale promotional campaign, custom stencils can help you achieve a professional and eye-catching look. With our advanced manufacturing capabilities, we can create stencils that accurately replicate your logo, text, or graphics, allowing you to make a lasting impression on your customers and audience.For businesses in the construction and industrial sectors, stencils are often used for safety and warning signage. Whether you need to mark floors, walls, or equipment with important safety messages, having a custom stencil made is a cost-effective and efficient way to communicate vital information. Our durable and long-lasting stencils are designed to withstand the toughest conditions, ensuring that your safety messages remain clear and visible for years to come.At {}, we understand that every business has unique needs and requirements when it comes to stencils. That is why we offer a comprehensive range of customization options, including material selection, size, and design. Our team works closely with each client to understand their specific goals and deliver stencils that meet their exact specifications. Whether you need a one-time order or ongoing supply of stencils, we are committed to providing outstanding customer service and top-quality products.In addition to our custom stencil manufacturing capabilities, we also offer a range of related services to support our clients' needs. From design assistance to fast turnaround times, we strive to be a one-stop solution for all your stencil requirements. Our commitment to excellence and innovation has made us a trusted partner for businesses across various industries, and we take pride in helping our clients achieve their goals through our stencil solutions.In conclusion, having a custom stencil made can be a game-changer for your business. From streamlining operations to creating visually impactful marketing materials, the benefits of custom stencils are vast. With our expertise and capabilities at {}, we are dedicated to helping businesses harness the power of stencils and achieve their desired outcomes. Whether you are looking for a simple labeling stencil or a complex branding tool, we have the knowledge and resources to bring your vision to fruition. Contact us today to learn more about our custom stencil solutions and take your business to the next level.

Tips for Improving Functional QA Testing in Your Company

Functional Qa, a leading quality assurance company, has recently announced the launch of its new and improved quality testing software. The company, known for its innovative and reliable QA solutions, is bringing cutting-edge technology to the table with this new product. This software promises to revolutionize the way companies conduct quality assurance testing, making the process more efficient and effective.Functional Qa has been a key player in the QA industry for several years, providing top-notch testing services to a wide range of businesses. The company has built a strong reputation for its ability to deliver accurate and comprehensive QA results, helping clients identify and address any potential issues with their products or services. With the launch of this new software, Functional Qa aims to further solidify its position as a leader in the QA field.The new software is designed to offer a range of features that will greatly enhance the quality testing process. One of the key highlights of the software is its advanced automation capabilities, which will allow companies to streamline their testing procedures and save valuable time and resources. This will enable businesses to conduct more thorough and extensive testing, leading to better overall product quality.In addition to its automation features, the software also boasts a user-friendly interface that is intuitive and easy to navigate. This will make it simple for teams to collaborate and communicate effectively throughout the testing process. Furthermore, the software will provide detailed and customizable reporting, giving companies the insight they need to make informed decisions about their products.The launch of this new software is an exciting development for Functional Qa, as it represents the company's commitment to innovation and advancement in the QA industry. By leveraging the power of cutting-edge technology, Functional Qa is demonstrating its dedication to providing its clients with the best possible QA solutions. The company's investment in this new software underscores its goal to stay ahead of the curve and continually adapt to the evolving needs of the QA market.With its track record of success and its strong focus on delivering exceptional QA results, Functional Qa is well-positioned to make a significant impact with this new software. The company's deep understanding of the QA process, coupled with its dedication to excellence, makes it a trusted partner for businesses seeking reliable and effective quality testing solutions.As Functional Qa continues to push the boundaries of what is possible in the QA industry, its new software is sure to make waves. By providing businesses with a powerful tool for conducting QA testing, Functional Qa is empowering companies to take control of their product quality and deliver the best possible experience to their customers.The launch of this new software is a clear reflection of Functional Qa's unwavering commitment to innovation and excellence. With its focus on driving positive change in the QA industry, the company is poised to continue making a significant impact in the years to come. Through its dedication to providing top-notch QA solutions, Functional Qa is helping businesses around the world achieve their quality testing goals and deliver exceptional products and services.

Essential Tips for Using a PCB Stencil for Manufacturing

PCB Company Introduces Innovative Stencil for Enhanced PCB ManufacturingIn the world of PCB (Printed Circuit Board) manufacturing, precision and accuracy are crucial. With the advancement of technology, the demand for high-quality PCB stencils has increased significantly. To meet this demand, {Company Name}, a leading PCB manufacturing company, has introduced an innovative stencil for PCB use. This new stencil is designed to provide enhanced precision and efficiency in the PCB manufacturing process.The new stencil is a result of extensive research and development efforts by the {Company Name} team. It is created using high-quality materials and advanced manufacturing techniques to ensure superior performance. The stencil is designed to accurately transfer solder paste onto the PCB, enabling precise placement of surface mount components during the assembly process.One of the key features of the new stencil is its durability. It is made from a highly durable material that can withstand the rigors of the PCB manufacturing process, including multiple uses and cleaning cycles. This durability ensures that the stencil maintains its precision and performance over time, resulting in consistent high-quality PCB assemblies.In addition to durability, the new stencil also offers improved accuracy. Its advanced design and manufacturing process result in fine detail and precise openings, allowing for precise and consistent solder paste deposition. This level of accuracy is essential for the assembly of increasingly complex and miniaturized electronic components.Moreover, the new stencil is designed for ease of use. It is compatible with various PCB manufacturing equipment and processes, making it easy to integrate into existing manufacturing workflows. This compatibility ensures a smooth transition for PCB manufacturers who choose to adopt the new stencil for their operations.{Company Name} is renowned for its commitment to innovation and quality in PCB manufacturing. With the introduction of this new stencil, the company aims to further solidify its position as a leader in the industry. The innovative features of the new stencil demonstrate {Company Name}'s dedication to addressing the evolving needs of PCB manufacturers and supporting them in achieving outstanding results.In a statement, {Spokesperson Name}, {Title} at {Company Name}, expressed enthusiasm about the new stencil and its potential impact on the industry. "We are thrilled to introduce this advanced stencil for PCB use. It represents our ongoing efforts to push the boundaries of innovation in PCB manufacturing. We believe that this stencil will empower our customers to achieve new levels of precision and efficiency in their manufacturing processes."The introduction of the new stencil has already generated significant interest within the PCB manufacturing community. Several industry experts have lauded {Company Name} for its commitment to advancing the field of PCB manufacturing and providing practical solutions to industry challenges.In conclusion, the introduction of the innovative stencil for PCB use by {Company Name} represents a significant development in the PCB manufacturing industry. The new stencil's durability, accuracy, and ease of use are poised to make a positive impact on the efficiency and quality of PCB assembly processes. As the demand for high-quality PCBs continues to grow, {Company Name} is well-positioned to meet the needs of PCB manufacturers with its cutting-edge solutions.

Printed Circuit Assembly: Everything You Need to Know

Pca Printed Circuit Assembly, a Leading Provider of Advanced Electronics Manufacturing SolutionsPca Printed Circuit Assembly is a premier provider of advanced electronics manufacturing solutions, serving a wide range of industries including aerospace, defense, medical, automotive, and telecommunications. With a strong focus on quality, innovation, and customer satisfaction, Pca Printed Circuit Assembly has established itself as a leader in the field of printed circuit assembly and electronics manufacturing.Founded in 1985, Pca Printed Circuit Assembly has grown to become a trusted partner for some of the world's leading technology companies, providing tailored solutions to meet the most demanding requirements. The company's state-of-the-art facilities and advanced manufacturing capabilities enable them to deliver high-quality products with exceptional precision and reliability.Pca Printed Circuit Assembly offers a comprehensive range of services, including PCB assembly, box build assembly, cable and harness assembly, test and fulfillment services, and more. The company's team of highly skilled engineers and technicians work closely with customers to understand their specific needs and develop customized solutions to meet their exact requirements.With a strong commitment to quality, Pca Printed Circuit Assembly has achieved several industry certifications, including ISO 9001, AS9100, ITAR, and IPC-A-610 Class 3. These certifications reflect the company's dedication to maintaining the highest standards of excellence in every aspect of its operations.One of Pca Printed Circuit Assembly's core strengths is its ability to adapt to the rapidly evolving technology landscape. The company invests heavily in research and development to stay at the forefront of industry trends and emerging technologies. This proactive approach allows Pca Printed Circuit Assembly to offer innovative solutions that give its customers a competitive advantage in their respective markets.In addition to its focus on technology and innovation, Pca Printed Circuit Assembly places a strong emphasis on sustainability and environmental responsibility. The company is committed to minimizing its impact on the environment by implementing energy-efficient practices, reducing waste, and utilizing eco-friendly materials wherever possible.As a customer-centric organization, Pca Printed Circuit Assembly is dedicated to building long-term partnerships based on trust, integrity, and mutual success. The company's team is always responsive and attentive to customers' needs, providing expert guidance and support throughout every stage of the manufacturing process.Pca Printed Circuit Assembly's commitment to excellence has earned it a reputation for delivering consistently superior products and services. The company has received numerous accolades and awards for its achievements in electronics manufacturing, further cementing its position as an industry leader.Looking ahead, Pca Printed Circuit Assembly is poised for continued growth and success as it continues to expand its capabilities, strengthen its partnerships, and explore new opportunities for innovation and expansion. With its unwavering dedication to quality, customer satisfaction, and technological advancement, Pca Printed Circuit Assembly is well-positioned to remain at the forefront of the electronics manufacturing industry for years to come.In conclusion, Pca Printed Circuit Assembly is a dynamic and forward-thinking company that is shaping the future of electronics manufacturing. With its relentless commitment to excellence, innovation, and customer satisfaction, Pca Printed Circuit Assembly is a trusted partner for companies seeking high-quality, advanced electronics manufacturing solutions.

What Is a Passive Capacitor and How Does It Work?

Passive Capacitor, a leading provider of advanced electronic components and solutions, has recently introduced a new line of cutting-edge passive capacitors designed to meet the growing demands of the electronics industry. With their commitment to innovation and excellence, Passive Capacitor has solidified its position as a trusted partner for businesses, providing superior quality products and exceptional customer service.The newly launched passive capacitors by Passive Capacitor are specifically engineered to enhance the performance and reliability of electronic devices and systems. With the increasing complexity and functionality of modern electronics, there is a rising need for high-quality passive components that can meet the rigorous demands of various applications.Passive Capacitor's state-of-the-art manufacturing facilities and stringent quality control measures ensure that their passive capacitors are produced to the highest standards. By leveraging cutting-edge technologies and industry-leading expertise, Passive Capacitor has been able to develop a range of passive capacitors that offer exceptional electrical performance, stability, and durability.In addition to their superior technical specifications, Passive Capacitor's new line of passive capacitors is also designed to be compact and space-efficient, making them ideal for use in densely populated electronic assemblies. This feature is particularly valuable for manufacturers looking to maximize the functionality of their products without compromising on quality or reliability.One of the key factors that set Passive Capacitor apart from its competitors is its unwavering commitment to research and development. The company invests heavily in continuous innovation, seeking to push the boundaries of what is possible in passive component technology. This proactive approach to product development allows Passive Capacitor to stay ahead of industry trends and anticipate the evolving needs of their customers.Furthermore, Passive Capacitor offers a comprehensive range of passive capacitors, catering to a diverse array of applications and industries. Whether it is for consumer electronics, automotive systems, telecommunications, or industrial equipment, Passive Capacitor has the expertise and resources to deliver tailored solutions that meet the specific requirements of their clients."We are excited to introduce our new line of passive capacitors, which are the result of our unwavering commitment to innovation and quality," said a spokesperson for Passive Capacitor. "As the demand for advanced electronic components continues to grow, we are dedicated to providing our customers with the most reliable and high-performing products available in the market."In an industry where reliability and performance are paramount, Passive Capacitor has earned a reputation for delivering exceptional products that consistently outperform the competition. By leveraging their extensive experience and technical expertise, the company has established itself as a trusted partner for businesses seeking top-of-the-line passive components.As the global electronics market continues to expand, the demand for exceptional passive capacitors is only set to increase. With their latest product launch, Passive Capacitor has demonstrated their ability to stay ahead of the curve and anticipate the evolving needs of the industry. Their new line of passive capacitors not only showcases their technical prowess but also cements their position as a leader in the field of electronic components.With a proven track record of excellence and a dedication to pushing the boundaries of what is possible in passive component technology, Passive Capacitor is well-positioned to meet the growing demands of the electronics industry. Their innovative products and commitment to customer satisfaction make them a valuable partner for businesses looking to elevate the performance and reliability of their electronic devices and systems.In conclusion, the introduction of Passive Capacitor's new line of passive capacitors is a testament to their ongoing dedication to excellence and innovation. As the electronics industry continues to evolve, businesses can rely on Passive Capacitor to provide them with the most advanced and reliable passive components available, setting the stage for a future of cutting-edge electronic technology.

How to Debug Dotnet Test for Improved Performance

Debugging Dotnet Test NewsIn the world of software development, debugging is a crucial process that ensures the proper functioning of applications and systems. As technology continues to advance, the need for efficient debugging tools has become increasingly important. This is where the company specializing in providing cutting-edge software solutions comes into play.With a strong focus on innovation and customer satisfaction, the company has consistently pushed the boundaries of software development. The company's team of skilled professionals is committed to delivering high-quality products and services to their clients. They have a proven track record of success in helping businesses and organizations across various industries meet their software needs.Recently, the company launched a new debugging tool called Debug Dotnet Test. This innovative tool is designed to help developers identify and fix issues in their .NET applications with ease. It offers a comprehensive set of features that make the debugging process more efficient and effective.One of the key features of Debug Dotnet Test is its user-friendly interface. The tool is designed to be intuitive and easy to use, allowing developers to quickly navigate through the debugging process. Additionally, it offers real-time insights into the application's performance, making it easier for developers to pinpoint and address any issues that may arise.Furthermore, Debug Dotnet Test provides advanced debugging capabilities that enable developers to trace and analyze the behavior of their applications in real time. This feature is particularly useful for identifying complex bugs and performance issues that may otherwise be difficult to detect. With the ability to identify and resolve issues quickly, developers can ensure the smooth operation of their .NET applications.In addition to its powerful debugging capabilities, Debug Dotnet Test also offers seamless integration with other development tools. This compatibility allows developers to incorporate the debugging tool into their existing workflows, streamlining the development process. As a result, developers can save time and resources while maintaining the high quality of their applications.The launch of Debug Dotnet Test demonstrates the company's ongoing commitment to providing innovative solutions to the software development community. By addressing the growing need for effective debugging tools, the company continues to empower developers with the tools they need to succeed in a fast-paced and competitive industry.As the demand for reliable and efficient debugging tools continues to grow, the company's dedication to innovation and customer satisfaction sets them apart as a leader in the software development industry. Their commitment to delivering top-notch products and services has earned them a strong reputation among developers and businesses alike.With Debug Dotnet Test, the company aims to further solidify its position as a trusted provider of software solutions. As they continue to push the boundaries of technology and drive innovation in the industry, the company remains dedicated to helping their clients achieve success through cutting-edge software products.