Effective Multilayer RF PCB Design for Improved Performance

By:Admin

One company that has been at the forefront of this innovation is {}. With a strong focus on research and development, the company has established itself as a leader in providing advanced PCB solutions for a wide range of industries including telecommunications, aerospace, automotive, and consumer electronics.

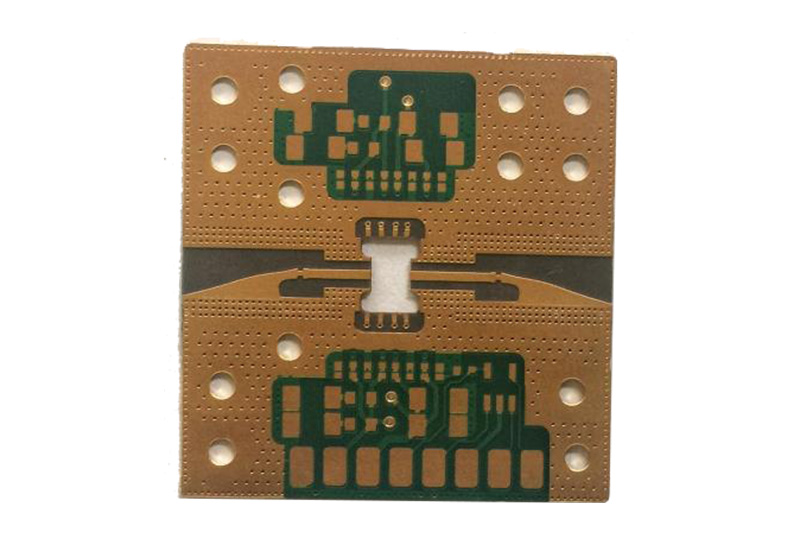

Multilayer RF PCBs are specially designed to handle high-frequency signals, making them ideal for applications such as wireless communication, radar systems, and satellite communication. The multilayer design allows for better signal integrity, reduced electromagnetic interference, and improved thermal management, which are essential for achieving optimal performance in today's electronic devices.

{}'s expertise in multilayer RF PCB design is evident in their capability to deliver high-quality solutions that meet the stringent requirements of modern electronic applications. By leveraging state-of-the-art design and fabrication techniques, the company ensures that its multilayer RF PCBs offer superior electrical performance, reliability, and durability.

One of the key advantages of {}'s multilayer RF PCBs is their ability to accommodate complex circuit designs in a compact form factor. This is instrumental in enabling the development of smaller and lighter electronic devices without compromising on performance. Additionally, the company's expertise in material selection and stackup design allows for the customization of PCBs to meet specific application requirements, providing customers with tailored solutions for their unique needs.

Moreover, {}'s commitment to quality and innovation is reflected in its investment in cutting-edge manufacturing capabilities. The company's advanced facilities are equipped with the latest machinery and inspection technologies, allowing for the precise fabrication of multilayer RF PCBs with tight tolerances and high reliability. This ensures that customers receive PCBs that not only meet their performance requirements but also adhere to the highest quality standards.

In addition to its technical capabilities, {}'s customer-centric approach sets it apart in the industry. The company works closely with its clients to understand their specific needs and challenges, offering comprehensive support throughout the design, development, and production processes. By fostering strong collaborative relationships, {} aims to provide its customers with unparalleled value and expertise, ultimately contributing to the success of their projects.

Looking ahead, {} remains committed to pushing the boundaries of multilayer RF PCB technology, driving advancements that will empower the next generation of electronic devices. With a focus on continuous innovation and customer satisfaction, the company is poised to further solidify its position as a leading provider of high-performance PCB solutions.

In conclusion, as the demand for high-frequency electronic applications continues to rise, the significance of multilayer RF PCB design cannot be overstated. With its expertise, technical capabilities, and customer-centric approach, {} is well-positioned to address the evolving needs of the industry and deliver advanced multilayer RF PCB solutions that pave the way for the next wave of innovation in electronic design.

Company News & Blog

High-Quality Assembled PCB SMT Services for Your Electronic Devices

Assembled PCB SMT Services Enhance Efficiency and Quality for Electronics ManufacturingIn today's rapidly evolving technological landscape, the demand for high-quality and efficient electronics manufacturing solutions has never been greater. Companies across various industries are constantly seeking ways to improve their production processes in order to stay ahead of the competition. This is where Assembled PCB SMT services come into play, offering a range of benefits that can greatly enhance the efficiency and quality of electronic manufacturing.Assembled PCB SMT, which stands for Surface Mount Technology, is a method used to assemble electronic circuits in which the components are mounted directly onto the surface of the printed circuit board (PCB). This process involves the use of automated equipment to place and solder the components onto the PCB, resulting in a more streamlined and efficient manufacturing process compared to traditional through-hole assembly methods.One company that has been at the forefront of providing high-quality Assembled PCB SMT services is {}. They have established themselves as a trusted partner for a wide range of industries, including telecommunications, automotive, consumer electronics, and medical devices. With their state-of-the-art facilities and advanced equipment, they are able to offer a comprehensive suite of PCB assembly services, including surface mount technology, through-hole assembly, and final product assembly and testing.The advantages of Assembled PCB SMT are numerous. One of the key benefits is the ability to achieve higher component densities on the PCB, leading to smaller and more compact electronic devices. This is particularly important in industries where space is a premium, such as automotive and aerospace. Additionally, the use of surface mount technology allows for faster production speeds and higher throughput, resulting in reduced lead times and overall cost savings for manufacturers.Furthermore, Assembled PCB SMT offers improved reliability and performance compared to through-hole assembly methods, as the solder joints are smaller and more consistent, resulting in better electrical connections and overall product quality. This is especially important for applications in which reliability is critical, such as medical devices and telecommunications equipment.In addition to their technical expertise, {} is also committed to providing exceptional customer service and support throughout the entire manufacturing process. They work closely with their clients to understand their specific requirements and provide customized solutions to meet their needs. Their team of experienced engineers and technicians ensure that every project is completed with the highest level of precision and quality.With the increasing demand for smaller, faster, and more reliable electronic devices, the importance of Assembled PCB SMT services in the manufacturing industry cannot be overstated. Companies like {} are playing a pivotal role in driving innovation and efficiency in electronics manufacturing, and their contributions are poised to have a lasting impact on a wide range of industries. As technology continues to advance, the need for high-quality PCB assembly services will only continue to grow, and companies that invest in Assembled PCB SMT will be well-positioned to succeed in the competitive global marketplace.

Complete Guide to SMD Mounting: Techniques and Best Practices

SMD Mounting: Revolutionizing the Electronics IndustryIn the fast-paced world of electronic manufacturing, precision and efficiency are paramount. As technology continues to advance, the demand for smaller, more powerful electronics is driving the need for advanced manufacturing techniques. SMD mounting, also known as surface mount device mounting, has become increasingly popular due to its ability to meet the demands of modern electronics manufacturing.SMD mounting is a process of directly mounting electronic components onto the surface of a printed circuit board (PCB). This method eliminates the need for holes or leads, allowing for smaller and more densely packed PCBs. The components used in SMD mounting are also smaller and lighter, making them ideal for the production of compact and high-performance electronics.{} is a leading expert in SMD mounting technology, providing advanced solutions for electronic manufacturing. With a focus on innovation and quality, {} has revolutionized the electronics industry with their state-of-the-art SMD mounting capabilities. The company’s commitment to research and development has enabled them to stay ahead of the curve, offering cutting-edge solutions for a wide range of industries.One of the key advantages of SMD mounting is its ability to improve the overall functionality and performance of electronic devices. By eliminating the need for through-holes, SMD mounting can reduce signal distortion and improve the overall signal integrity of the PCB. This results in electronics that are more reliable and efficient, making them ideal for a variety of applications.In addition to improved performance, SMD mounting also offers significant cost savings for electronic manufacturers. The smaller size and weight of SMD components reduce material and shipping costs, while also enabling more efficient use of PCB real estate. This allows manufacturers to produce smaller, lighter, and more cost-effective electronics without sacrificing performance or quality.{}’s expertise in SMD mounting has allowed them to cater to a diverse range of industries, including consumer electronics, telecommunications, automotive, and aerospace. With a focus on precision and reliability, {} has earned a reputation for delivering innovative solutions that meet the demands of the modern electronics industry.The future of electronic manufacturing is undoubtedly driven by the demand for smaller, more powerful devices. As consumer expectations continue to evolve, the need for advanced manufacturing techniques such as SMD mounting will only grow. By leveraging the expertise of companies like {}, electronic manufacturers can stay ahead of the curve and continue producing cutting-edge electronics that meet the demands of today’s tech-savvy consumers.In conclusion, SMD mounting is revolutionizing the electronics industry by enabling the production of smaller, more powerful, and more cost-effective electronic devices. As the demand for advanced manufacturing techniques continues to grow, companies like {} are at the forefront of innovation, providing state-of-the-art solutions for a wide range of industries. With a focus on precision, reliability, and efficiency, {} is shaping the future of electronic manufacturing and driving the industry forward into a new era of innovation.

Top PCB Manufacturer Offers Competitive Quotes for Quality Printed Circuit Boards

Pcb Quote, a leading printed circuit board (PCB) manufacturer, has recently announced a significant milestone in its growth trajectory. The company has expanded its market reach and solidified its position as a key player in the global PCB industry. With a strong focus on innovation, quality, and customer satisfaction, Pcb Quote has emerged as a preferred partner for businesses seeking reliable and high-performance PCB solutions.Established in [year], Pcb Quote has built a reputation for excellence in the PCB manufacturing sector. The company's state-of-the-art facilities and cutting-edge technology allow it to meet the diverse needs of clients across various industries, including automotive, telecommunications, healthcare, aerospace, and more. Pcb Quote's commitment to delivering top-notch PCBs with uncompromised quality has earned it the trust of customers worldwide.As part of its growth strategy, Pcb Quote has invested heavily in research and development to stay at the forefront of technological advancements in the PCB industry. This has enabled the company to offer a comprehensive range of PCB products, including single-sided, double-sided, and multi-layer boards, as well as flexible and rigid-flex PCBs. In addition, Pcb Quote provides custom PCB solutions tailored to the specific requirements of clients, ensuring that their unique needs are met with precision and efficiency.Furthermore, Pcb Quote has focused on building strong relationships with its customers by providing unparalleled customer service and technical support. The company's team of experienced professionals works closely with clients to understand their goals and challenges, offering valuable insights and guidance throughout the PCB manufacturing process. This collaborative approach has resulted in long-term partnerships with many clients, further solidifying Pcb Quote's position as a trusted PCB supplier.In line with its commitment to quality, Pcb Quote adheres to stringent quality control measures at every stage of the manufacturing process. From initial design and prototyping to production and testing, the company maintains strict quality standards to ensure that its PCBs meet the highest specifications and performance benchmarks. As a result, Pcb Quote has been able to consistently deliver reliable, durable, and high-performance PCBs that exceed customer expectations.In addition to its focus on quality and innovation, Pcb Quote places a strong emphasis on environmental sustainability and corporate responsibility. The company has implemented eco-friendly practices in its manufacturing processes, minimizing its environmental impact and promoting a greener, more sustainable future. Pcb Quote's commitment to sustainability reflects its dedication to ethical and responsible business practices.Looking ahead, Pcb Quote is poised for continued growth and success in the PCB industry. With a proven track record of excellence, a commitment to customer satisfaction, and a forward-thinking approach to technology and innovation, the company is well-positioned to meet the evolving needs of the market and expand its global presence. Supported by a team of industry experts and a strong customer base, Pcb Quote is set to maintain its leadership position in the PCB manufacturing sector for years to come.In conclusion, Pcb Quote's recent announcement of its growth milestone underscores the company's dedication to excellence, innovation, and customer satisfaction in the PCB industry. As it continues to expand its market reach and solidify its position as a key player in the global PCB market, Pcb Quote remains committed to delivering high-quality, reliable, and cutting-edge PCB solutions to its diverse clientele. With a focus on sustainability, customer service, and technological advancement, Pcb Quote is well-equipped to lead the way in the ever-evolving world of PCB manufacturing.

Top Quality Options for Component Replacement in the News

Alternative Components (AC), a leading supplier of electronic components and parts, has been making waves in the industry with their innovative and high-quality products. With a strong commitment to customer satisfaction and a focus on delivering top-notch components, AC has become a go-to source for businesses and individuals looking for reliable electronic parts.Established in 2005, AC has quickly grown to become a trusted name in the industry, offering a wide range of components including resistors, capacitors, connectors, and much more. The company has built a strong reputation for providing high-quality products that meet the demands of its customers.One of the key factors that sets AC apart from other component suppliers is their emphasis on alternative and hard-to-find components. The company has a vast inventory of obsolete and discontinued components, making it a valuable resource for customers in need of specific parts for their projects.In addition to their extensive product range, AC also prides itself on excellent customer service and support. The company has a team of knowledgeable and experienced professionals who are dedicated to helping customers find the right components for their needs. Whether it's a large-scale industrial project or a small DIY endeavor, AC is committed to ensuring that every customer receives the assistance they need.Furthermore, AC understands the importance of quality and reliability in the components they supply. The company has stringent quality control measures in place to ensure that every product meets the highest standards. This dedication to quality has earned AC a loyal customer base and a reputation for excellence in the industry.In recent news, AC has announced the launch of several new products aimed at meeting the changing needs of the market. These products include advanced resistors, state-of-the-art capacitors, and revolutionary connectors that offer enhanced performance and reliability. With these new offerings, AC is poised to further solidify its position as a leader in the electronic components industry.One of the standout products in the new lineup is the advanced resistors, which are designed to meet the demands of modern electronic devices. These resistors offer improved efficiency and stability, making them ideal for a wide range of applications. Whether it's for consumer electronics, automotive systems, or industrial equipment, AC's new resistors are engineered to deliver superior performance.Additionally, AC's new capacitors are designed to push the boundaries of performance and reliability. These capacitors are built to withstand the rigors of demanding applications while delivering exceptional performance. With advanced features such as high capacitance and low ESR, these capacitors are set to become a game-changer in the industry.Moreover, AC's new line of connectors offers unmatched reliability and versatility. These connectors are engineered with precision and durability in mind, making them suitable for a variety of applications. Whether it's for data communication, power transmission, or signal processing, AC's connectors are designed to provide seamless connectivity and long-term reliability.In response to the growing demand for environmentally friendly and sustainable components, AC has also introduced a range of eco-friendly products. These components are manufactured using green practices and materials, making them a responsible choice for businesses and individuals looking to reduce their environmental footprint.With their commitment to innovation and customer satisfaction, AC is well-positioned to continue leading the way in the electronic components industry. The company's dedication to providing high-quality, reliable, and sustainable products has earned it a reputation as a trusted partner for businesses and individuals alike.As AC continues to expand its product offerings and customer support, it is clear that the company is focused on meeting the evolving needs of the industry. With their dedication to quality, reliability, and innovation, AC is poised to remain a top choice for electronic components for years to come.

Fast PCB Fabrication - Get Your Circuit Boards Quickly Made

Quick PCB Fabrication: Revolutionizing the Electronics Manufacturing IndustryIn today's fast-paced world, the demand for quick and efficient printed circuit board (PCB) fabrication has never been higher. As electronic devices continue to permeate every aspect of our lives, the need for reliable and rapid PCBs has become a critical component of the electronics manufacturing industry. With this in mind, {Company Name}, a leading provider of advanced PCB solutions, has been at the forefront of revolutionizing the way PCBs are fabricated, meeting the growing demands for fast and high-quality PCB production.{Company Name} is a global leader in the electronics manufacturing industry, with a strong focus on innovation, quality, and customer satisfaction. With state-of-the-art facilities and cutting-edge technology, the company has been able to streamline the PCB fabrication process, offering quick turnarounds without compromising on quality.The company's commitment to excellence and continuous improvement has led to the development of a highly efficient PCB fabrication process that delivers fast and reliable results. By leveraging advanced manufacturing techniques and proprietary technologies, {Company Name} is able to produce high-quality PCBs in a fraction of the time it takes traditional manufacturers.One of the key advantages of {Company Name}'s quick PCB fabrication process is its ability to significantly reduce lead times. This means that customers can expect their PCBs to be manufactured and delivered in a matter of days, rather than weeks or months. This rapid turnaround time is especially beneficial for companies in the fast-paced electronics industry, where time-to-market is crucial for success.Furthermore, {Company Name} offers a wide range of PCB fabrication services, including single-sided, double-sided, and multilayer PCBs, as well as flexible and rigid-flex PCBs. This comprehensive suite of services allows customers to find the perfect solution for their specific needs, all while benefiting from quick turnarounds and exceptional quality.In addition to its quick turnaround times, {Company Name} prides itself on its unwavering commitment to quality. The company adheres to strict quality standards throughout the entire PCB fabrication process, ensuring that every PCB that leaves its facilities meets the highest industry standards. This dedication to quality has earned {Company Name} a stellar reputation as a trusted and reliable provider of PCB solutions.Moreover, {Company Name} also offers personalized customer support to ensure that each customer's unique needs are met. From initial design consultations to final production, the company's team of expert engineers and technicians work closely with customers to deliver tailored solutions that exceed expectations.As the electronics industry continues to evolve, the demand for quick and high-quality PCB fabrication will only continue to grow. With its innovative approach and unwavering commitment to excellence, {Company Name} is well-positioned to meet this demand and lead the way in revolutionizing the electronics manufacturing industry.In conclusion, {Company Name} is redefining the PCB fabrication process with its quick turnarounds, high-quality products, and personalized customer support. As the demand for fast and reliable PCBs continues to rise, {Company Name} stands ready to meet the needs of the electronics industry and drive innovation forward. With its advanced manufacturing capabilities and unwavering commitment to customer satisfaction, {Company Name} is poised to revolutionize the way PCBs are fabricated and pave the way for the future of electronics manufacturing.

Efficient PCB Assembly Services for Quick Turnaround Time

Fast Turn PCB Assembly, a leading provider of electronic manufacturing services, is revolutionizing the industry with its cutting-edge technology and commitment to superior quality and fast turnaround times.With over 20 years of experience, Fast Turn PCB Assembly has established itself as a trusted partner for industries ranging from aerospace and defense to medical and automotive. The company has earned a reputation for excellence in PCB assembly, offering a wide range of services including quick-turn prototypes, small batch production, and full-scale manufacturing.Fast Turn PCB Assembly stands out from its competitors by prioritizing customer satisfaction above all else. The company is dedicated to providing the highest quality products and services, and has implemented a strict quality control system to ensure that every product that leaves its facility meets the highest industry standards.One of the key factors that sets Fast Turn PCB Assembly apart is its commitment to fast turnaround times. The company understands the importance of speed in today's fast-paced market, and has invested in state-of-the-art equipment and streamlined processes to ensure that customers receive their products in a timely manner.Fast Turn PCB Assembly's latest innovation is its advanced PCB assembly technology, which allows for faster and more efficient production. This cutting-edge technology has significantly reduced lead times and increased production capacity, enabling the company to meet the growing demand for quick-turn prototypes and small batch production.In addition to its advanced technology and fast turnaround times, Fast Turn PCB Assembly also offers a range of value-added services to support its customers throughout the entire manufacturing process. These services include design for manufacturability (DFM) analysis, component sourcing, and supply chain management, ensuring that customers receive comprehensive support from start to finish.The company's commitment to excellence and customer satisfaction has earned it a loyal customer base, and its reputation for quality and reliability continues to attract new clients from around the world. From startups to Fortune 500 companies, Fast Turn PCB Assembly is trusted by industry leaders to deliver superior PCB assembly solutions.As the demand for fast-turn PCB assembly continues to grow, Fast Turn PCB Assembly remains at the forefront of the industry, continually pushing the boundaries of what is possible and setting new standards for quality and efficiency. With its relentless dedication to innovation and customer service, Fast Turn PCB Assembly is poised to remain a driving force in the electronic manufacturing industry for years to come.In conclusion, Fast Turn PCB Assembly is a trailblazer in the electronic manufacturing services industry, known for its advanced technology, fast turnaround times, and unwavering commitment to customer satisfaction. With a focus on quality, efficiency, and innovation, the company is well-positioned to continue leading the way in PCB assembly for years to come.

Understanding the Function and Benefits of Passive Crystal Oscillators

Passive Crystal Oscillator: The Future of Precision Timekeeping and Frequency ControlIn today's world, precision timekeeping and frequency control are crucial in a wide range of applications, including telecommunications, navigation systems, medical devices, and many more. Companies are constantly looking for advanced solutions to meet the increasing demand for accuracy and stability in their products. This is where Passive Crystal Oscillator technology comes into play. {Company Name}, a leading provider of electronic components and solutions, has recently developed an innovative Passive Crystal Oscillator that promises to revolutionize the way precision timekeeping and frequency control are achieved in various industries. The company, known for its expertise in designing and manufacturing high-quality electronic components, has once again proven its commitment to innovation and excellence with this groundbreaking technology.So, what exactly is a Passive Crystal Oscillator and what makes it stand out from traditional solutions? Unlike traditional crystal oscillators, which require an external power source to operate, Passive Crystal Oscillators are entirely self-sustaining, making them highly reliable and energy-efficient. This unique feature makes them an ideal choice for battery-powered devices and applications where power consumption is a critical factor.The Passive Crystal Oscillator developed by {Company Name} offers unparalleled frequency stability and accuracy, making it suitable for a wide range of critical applications. With its advanced design and manufacturing process, the oscillator provides excellent performance in terms of temperature stability, aging characteristics, and low phase noise. This makes it an ideal solution for demanding applications where precision timing and frequency control are essential.One of the key advantages of {Company Name}'s Passive Crystal Oscillator is its compact and low-profile design, which allows for easy integration into various devices and systems. This makes it an attractive choice for manufacturers looking to reduce the size and weight of their products without compromising on performance. Furthermore, the oscillator's robust construction and high shock and vibration resistance make it suitable for use in harsh operating environments, further expanding its potential applications.It is worth noting that {Company Name} has a strong track record of delivering high-quality electronic components to a wide range of industries, including aerospace, automotive, industrial, and consumer electronics. The company's commitment to innovation and excellence has earned it a reputation as a trusted partner for companies seeking advanced electronic solutions. With the introduction of the Passive Crystal Oscillator, {Company Name} continues to demonstrate its dedication to pushing the boundaries of technology and providing industry-leading solutions to its customers.The potential impact of {Company Name}'s Passive Crystal Oscillator in the market is significant. With its superior performance, reliability, and energy efficiency, the oscillator has the potential to become the new standard in precision timekeeping and frequency control. It is expected to open up new possibilities for advancements in various industries, enabling companies to develop innovative products with improved performance and efficiency.As the demand for precision timekeeping and frequency control continues to grow, companies are increasingly turning to advanced solutions such as Passive Crystal Oscillators to meet their requirements. {Company Name}, with its proven expertise and commitment to innovation, is well-positioned to lead the way in this rapidly evolving field. With its new Passive Crystal Oscillator technology, the company is set to shape the future of precision timing and frequency control, providing industry-leading solutions that redefine the standard for performance and reliability.In conclusion, the introduction of {Company Name}'s Passive Crystal Oscillator represents a significant milestone in the field of precision timekeeping and frequency control. With its advanced technology, superior performance, and wide-ranging potential applications, the oscillator has the potential to revolutionize the way companies approach precision timing and frequency control. {Company Name} continues to demonstrate its leadership in electronic component innovation, providing industry-leading solutions that drive advancements across various sectors.

High-Quality Printed Circuit Board Assembly Services - All You Need to Know

Printed Circuit Board Assembly (PCBA) is an essential part of electronic devices, and it plays a crucial role in the functionality of various electronic products. PCBA typically involves soldering various electronic components onto a printed circuit board, which is then used in devices such as smartphones, computers, and other electronic gadgets.{Company Name} is a leading manufacturer of PCBA, specializing in high-quality electronic assembly and manufacturing services. With a strong focus on innovation and technology, {Company Name} has built a reputation for delivering reliable and cost-effective PCBA solutions to a wide range of industries.Recently, {Company Name} announced the launch of its latest generation of PCBA, which features advanced technology and enhanced capabilities. The new PCBA is designed to meet the increasing demand for smaller, more powerful, and more energy-efficient electronics, offering customers a reliable and efficient solution for their electronic assembly needs.The new PCBA from {Company Name} incorporates the latest advancements in manufacturing technology, including state-of-the-art automated assembly equipment and advanced quality control processes. This allows {Company Name} to produce PCBA with higher precision and reliability, meeting the stringent quality standards required by the electronics industry.In addition to its advanced manufacturing capabilities, {Company Name} is committed to sustainability and environmental responsibility. The company has implemented eco-friendly practices in its manufacturing process, ensuring that its PCBA products are produced in a sustainable and environmentally responsible manner.With the launch of its latest generation of PCBA, {Company Name} aims to further solidify its position as a leading provider of electronic assembly solutions. The company's dedication to innovation and quality, combined with its commitment to sustainability, sets it apart as a trusted and reliable partner for businesses looking for high-quality PCBA solutions.{Company Name} is also focused on providing exceptional customer service, offering comprehensive technical support and personalized solutions to meet the unique needs of its clients. The company's team of experienced engineers and technicians are dedicated to delivering the highest level of service, ensuring that customers receive the best possible PCBA solutions for their specific requirements.As the demand for advanced electronic devices continues to grow, {Company Name} is well-positioned to meet the needs of the industry with its latest generation of PCBA. The company's commitment to innovation, quality, and sustainability, combined with its exceptional customer service, makes it a top choice for businesses seeking reliable and efficient electronic assembly solutions.In conclusion, {Company Name}'s latest generation of PCBA represents a significant advancement in electronic assembly technology, offering customers a reliable and efficient solution for their electronic manufacturing needs. With its dedication to innovation, quality, and sustainability, {Company Name} is poised to continue leading the industry in providing high-quality PCBA solutions to a wide range of industries.

Guide to Reflow Soldering Process: Everything You Need to Know

Smt Reflow Soldering Process Revolutionizes Electronics ManufacturingThe electronics manufacturing industry has always been at the forefront of innovation and technological advancement. With the constant demand for smaller, faster, and more efficient electronic products, manufacturers are continuously looking for ways to improve their production processes. One such advancement in electronics manufacturing is the Surface Mount Technology (SMT) reflow soldering process, which has revolutionized the way electronic components are soldered onto circuit boards. The SMT reflow soldering process is a method of attaching electronic components to a printed circuit board (PCB). It involves using solder paste, which is a mixture of solder particles and flux, to temporarily attach the components to their pads on the PCB. The PCB is then heated in a reflow oven, causing the solder paste to melt, creating a permanent bond between the components and the board. This process allows for high precision soldering of tiny components, making it an essential part of modern electronics manufacturing.One of the leading companies in the development and manufacturing of SMT reflow soldering equipment is {}. They have been at the forefront of innovation in the electronics manufacturing industry for over two decades. With a focus on providing high-quality and reliable equipment, they have established themselves as a trusted partner for electronics manufacturers worldwide.The company's SMT reflow soldering equipment is known for its precision, efficiency, and versatility. Their machines are designed to handle the soldering of a wide range of electronic components, from small surface mount devices to larger through-hole components. Their advanced reflow ovens are equipped with state-of-the-art heating elements and temperature control systems, ensuring that the soldering process is carried out with the highest level of accuracy and consistency.In addition to their cutting-edge equipment, {} also provides comprehensive technical support and training services to their customers. They understand the importance of having well-trained personnel operating their equipment, and they are committed to ensuring that their clients have the knowledge and skills necessary to maximize the performance of their soldering machines.With the increasing demand for smaller and more complex electronic devices, the SMT reflow soldering process has become an indispensable part of electronics manufacturing. The ability to solder components with high precision and reliability is crucial for producing advanced electronic products that meet the needs of today's technology-driven society.{}'s dedication to continuous improvement and innovation has made them a leader in the SMT reflow soldering equipment market. Their commitment to quality and customer satisfaction has earned them the trust and loyalty of electronics manufacturers around the world.As the electronics industry continues to evolve, the importance of advanced manufacturing processes like SMT reflow soldering will only continue to grow. With the expertise and dedication of companies like {}, the future of electronics manufacturing looks bright, with endless possibilities for innovation and advancement.

Create Custom Stencils with Laser Technology for Precision Designs

Laser Stencil Maker (LSM) is revolutionizing the manufacturing industry with its state-of-the-art stencil making technology. The company, which was founded in 2005, has quickly become a leader in the industry, providing high-quality stencils for a wide range of applications.LSM's stencil making process utilizes the latest in laser cutting technology to produce precise and reliable stencils for use in electronic assembly, PCB manufacturing, and other industrial applications. The company's commitment to quality and innovation has made it a go-to choice for manufacturers looking for reliable stencils that can meet their exact specifications.One of the key advantages of LSM's stencils is their precision. The company's laser cutting technology allows for the creation of stencils with incredibly fine detail, ensuring that every component is accurately placed on the PCB. This level of precision is essential for the successful manufacturing of electronic devices, where even minor errors can lead to costly defects and production delays.In addition to precision, LSM's stencils are also known for their durability. The company uses high-quality materials and advanced manufacturing processes to create stencils that can withstand the rigors of high-volume production. This means that manufacturers can rely on LSM's stencils to deliver consistent results, even in the most demanding production environments.Another key advantage of LSM's stencils is their versatility. The company can create stencils for a wide range of applications, from simple single-layer PCBs to complex multi-layer designs. This flexibility allows manufacturers to rely on LSM for all of their stencil needs, streamlining the production process and reducing the need to work with multiple suppliers.To further support its customers, LSM also offers a range of additional services, including design assistance and rapid prototyping. The company's team of experienced engineers can work with manufacturers to optimize their stencil designs, ensuring that they meet the unique requirements of each application. Additionally, LSM's rapid prototyping services allow manufacturers to quickly test and refine their stencil designs, accelerating the product development process.As a testament to its commitment to quality, LSM is proud to be ISO 9001 certified. This certification reflects the company's dedication to maintaining the highest standards of quality in its manufacturing processes, ensuring that its stencils consistently meet the needs of its customers.In addition to its commitment to quality, LSM is also dedicated to sustainability. The company has implemented a range of environmentally friendly practices in its manufacturing processes, including the use of recyclable materials and the minimization of waste. This commitment to sustainability has made LSM a preferred supplier for manufacturers looking to minimize their environmental impact.Looking to the future, LSM is committed to continued innovation in stencil making technology. The company is constantly investing in research and development to identify new ways to improve its processes and deliver even greater value to its customers. As the manufacturing industry continues to evolve, LSM remains at the forefront, providing manufacturers with the stencils they need to succeed in an increasingly competitive market.In conclusion, Laser Stencil Maker is a leading provider of high-quality stencils for the manufacturing industry. With its precision, durability, versatility, and commitment to quality and sustainability, the company has established itself as a reliable partner for manufacturers looking to streamline their production processes and achieve the highest standards of quality. As LSM continues to innovate and expand its capabilities, it will undoubtedly remain a key player in the manufacturing industry for years to come.