Understanding the Importance of Content Intelligence for PCB Manufacturing

By:Admin

[City, State]

[Company Name], a leading provider of advanced technology solutions, is set to revolutionize the electronics industry with its cutting-edge vision PCB technology. Vision PCB, which stands for Printed Circuit Board, encompasses the integration of artificial intelligence and advanced sensors to optimize the functionality and performance of electronic devices.

With the rise of smart technology and the Internet of Things (IoT), the demand for highly advanced and efficient PCBs has surged. Traditional PCBs are limited in their ability to adapt to changing environmental conditions, leading to decreased performance and reliability. Vision PCB, on the other hand, is equipped with AI algorithms that allow it to dynamically adjust to varying conditions, ensuring optimal performance at all times.

The integration of advanced sensors further enhances the capabilities of Vision PCB. These sensors enable real-time monitoring of environmental factors such as temperature, humidity, and pressure, allowing the PCB to make instant adjustments to its operations. This level of adaptability is unparalleled in the electronics industry, setting a new standard for PCB technology.

In addition to its adaptability, Vision PCB is also designed to improve energy efficiency. By constantly analyzing and optimizing its power consumption, it minimizes wastage and prolongs the lifespan of electronic devices. This is particularly valuable in the context of IoT devices, where energy efficiency is a critical factor in overall performance and longevity.

Furthermore, Vision PCB has the potential to significantly reduce maintenance and repair costs for electronic devices. Its ability to self-diagnose and address issues in real time minimizes the need for manual intervention, thus reducing downtime and costs associated with repairs. This is a game-changer for industries relying on electronic systems, such as manufacturing, healthcare, and transportation.

[Company Name] is at the forefront of this groundbreaking technology, leveraging its expertise in AI and sensor integration to develop Vision PCB. The company has a proven track record of delivering innovative solutions to its clients across various industries, and Vision PCB is poised to further solidify its position as a leader in the electronics industry.

[Company Name] is committed to working closely with partners and clients to integrate Vision PCB into their products and systems. This collaboration is essential to harness the full potential of Vision PCB and maximize its benefits across different applications. The company is already in talks with several major players in the electronics industry to explore potential partnerships and collaborations.

The potential impact of Vision PCB on the electronics industry cannot be overstated. Its ability to adapt, optimize energy efficiency, and minimize maintenance costs will undoubtedly reshape the way electronic devices are designed, manufactured, and operated. As the demand for smart and connected devices continues to grow, Vision PCB is well-positioned to meet the evolving needs of the market.

In conclusion, [Company Name] is on the cusp of revolutionizing the electronics industry with its groundbreaking Vision PCB technology. By combining artificial intelligence and advanced sensors, Vision PCB offers unparalleled adaptability, energy efficiency, and cost savings. With the company's proven track record of innovation and commitment to collaboration, Vision PCB is set to transform the way electronic devices are designed, manufactured, and operated.

For more information about Vision PCB and [Company Name]'s range of technology solutions, please visit [company website].

Company News & Blog

High-Quality Printing Services for Your Business Growth

PBC Printing, one of the leading printing companies in the industry, has made significant advancements in the field of print technology. With a strong emphasis on quality, efficiency, and customer satisfaction, PBC Printing has become a trusted partner for businesses and organizations looking for high-quality printing solutions.The company's commitment to excellence is evident in its state-of-the-art printing facilities, equipped with the latest printing technology and a highly skilled team of professionals. PBC Printing offers a wide range of printing services including offset printing, digital printing, large format printing, and packaging solutions. This versatility allows the company to cater to a diverse clientele, including businesses, advertising agencies, publishers, and individual clients.In addition to its printing capabilities, PBC Printing also provides comprehensive pre-press and post-press services, ensuring that every aspect of the printing process is handled with precision and attention to detail. From file preparation and proofing to finishing and binding, the company's team of experts ensures that every project meets the highest standards of quality.One of the key factors that sets PBC Printing apart from its competitors is its commitment to sustainability. The company has invested in environmentally friendly printing technology and materials, minimizing its impact on the environment while delivering exceptional printing results. This focus on sustainability has earned PBC Printing a reputation for being an eco-friendly and socially responsible printing partner.Moreover, PBC Printing has established a strong track record of delivering printing solutions on time and within budget. The company understands the importance of meeting deadlines and works tirelessly to ensure that every project is completed to the client's satisfaction. This dedication to customer service has earned PBC Printing a loyal customer base and a reputation for reliability and professionalism.In line with its commitment to innovation, PBC Printing continues to invest in research and development, constantly exploring new technologies and techniques to improve its printing capabilities. The company's dedication to staying ahead of the curve in the ever-evolving printing industry has positioned it as a leader in the market.Additionally, PBC Printing places a strong emphasis on building strong and lasting relationships with its clients. The company takes the time to understand each client's unique needs and preferences, offering personalized solutions that exceed expectations. PBC Printing's focus on customer satisfaction has resulted in long-standing partnerships with many of its clients, who continue to rely on the company for their printing needs.In conclusion, PBC Printing has established itself as a leading force in the printing industry, known for its commitment to excellence, sustainability, innovation, and customer satisfaction. With its state-of-the-art facilities, versatile printing capabilities, and dedication to quality, the company continues to set the benchmark for printing services. As PBC Printing continues to evolve and expand its offerings, it remains dedicated to providing the highest level of service and expertise to its clients, solidifying its position as a trusted printing partner.

Top Quality HDI PCB Production for Your Electronic Needs

HDI PCB Production: Taking Innovation to the Next LevelIn the constantly evolving world of technology, the demand for high-quality PCB (Printed Circuit Board) production is on the rise. With the increasing complexity of electronic devices, there is a need for PCBs that can support more advanced functionalities in a compact and efficient manner. This is where HDI (High Density Interconnect) PCB production comes into play.One company that has been at the forefront of HDI PCB production is {}. With a track record of delivering cutting-edge electronic solutions, {} has established itself as a leader in the industry.Founded in {}, {} has grown to become a top-tier provider of advanced PCB production services. The company's commitment to innovation and quality has set it apart from its competitors. With a focus on research and development, {} continues to push the boundaries of what is possible in PCB production.One of the key areas of expertise for {} is HDI PCB production. HDI technology allows for more complex and densely packed PCBs, enabling the design and manufacture of smaller and more powerful electronic devices. This is especially crucial in industries such as telecommunications, medical devices, and aerospace, where space is at a premium and performance is non-negotiable.{}'s state-of-the-art facilities are equipped with the latest machinery and technology to support HDI PCB production. With a team of highly skilled engineers and technicians, the company is able to handle the entire production process in-house, ensuring strict quality control and timely delivery.The company's dedication to customer satisfaction is reflected in its ability to offer customized solutions for a wide range of industries. Whether it's a complex multi-layer HDI PCB for a medical device or a high-speed, high-density board for a telecommunications application, {} has the expertise and capabilities to meet the unique requirements of its clients.{}'s commitment to sustainability and environmental responsibility is also evident in its production processes. The company adheres to strict environmental standards and utilizes eco-friendly materials in its PCB production, minimizing its carbon footprint and contributing to a greener future.As the demand for smaller, more powerful electronic devices continues to grow, the importance of HDI PCB production cannot be overstated. With {} at the helm, customers can be assured of top-notch quality, innovation, and reliability in their PCB solutions.In conclusion, HDI PCB production is a critical component of the ever-evolving electronic industry, and {} is leading the charge with its cutting-edge technology, unwavering commitment to quality, and customer-centric approach. As the company continues to innovate and push the boundaries of what is possible in PCB production, it is clear that {} is poised to make a lasting impact on the electronic industry for years to come.

Durable and Versatile Metal Core Board: A Must-Have for Your Projects

Metal Core Board, a vital component in the manufacturing of various electronic devices, is making waves in the industry due to its exceptional properties and applications. This specialized circuit board has been gaining attention for its high thermal conductivity, excellent mechanical stability, and superior electrical insulation. These properties make it an ideal choice for applications in industries such as automotive, aerospace, and LED lighting.Metal Core Board, also known as MCPCB, is a type of specialized circuit board that has a layer of metal in its construction. This metal layer provides excellent heat dissipation properties, making it suitable for applications where high levels of heat are generated. This feature is particularly valuable in electronics that demand efficient cooling, such as LED lighting, power supplies, and automotive electronics.One of the key players in the Metal Core Board industry is the company {}, which has been at the forefront of developing and manufacturing high-quality MCPCBs for a wide range of applications. With a strong focus on research and development, the company has consistently delivered innovative solutions that meet the demanding requirements of the modern electronics industry.{} is known for its ability to customize Metal Core Boards to meet the specific needs of its customers. The company's in-house design and manufacturing capabilities allow it to produce MCPCBs in various shapes, sizes, and materials, catering to a diverse range of applications. This flexibility has made {} a preferred supplier for many leading manufacturers in the automotive, aerospace, and LED lighting industries.In addition to its customization capabilities, {} has also established a reputation for its strict quality control processes. The company adheres to international standards and regulations, ensuring that its products meet the highest quality and safety requirements. This commitment to quality has earned {} the trust and confidence of its customers, further solidifying its position as a reliable supplier of Metal Core Boards.One of the key advantages of Metal Core Boards is their ability to improve the overall performance and reliability of electronic devices. The excellent thermal conductivity of the metal layer allows for efficient heat dissipation, which in turn extends the lifespan of electronic components. This is especially important in applications where thermal management is critical, such as LED lighting fixtures and power supplies.The automotive industry is another sector where Metal Core Boards are seeing increased adoption. The growing demand for electric vehicles and advanced driver-assistance systems has created a need for high-performance electronics with superior thermal management capabilities. MCPCBs are well-suited for these applications due to their ability to withstand high temperatures and maintain stable performance under challenging conditions.Furthermore, Metal Core Boards are also finding applications in the aerospace industry, where advanced electronics are used in avionics and communication systems. The ability of MCPCBs to withstand vibration and mechanical stress makes them an ideal choice for aerospace applications, where reliability and performance are of utmost importance.As the demand for high-performance electronics continues to rise across various industries, the importance of Metal Core Boards is expected to grow significantly. With their unique combination of thermal conductivity, mechanical stability, and electrical insulation, MCPCBs are poised to play a crucial role in the development of next-generation electronic devices.In conclusion, Metal Core Boards have emerged as a key enabler for the design and manufacture of high-performance electronic devices. With their exceptional properties and wide-ranging applications, MCPCBs are proving to be an essential component in industries such as automotive, aerospace, and LED lighting. As companies like {} continue to innovate and push the boundaries of what is possible with Metal Core Boards, the future looks bright for this specialized circuit board technology.

Essential Tips for Successfully Engineering PCBs

Pcb Engineering Expands its Business OperationsPcb Engineering, a leading engineering and manufacturing company, is expanding its business operations to better serve its growing customer base. With a focus on providing high-quality and innovative engineering solutions, Pcb Engineering is committed to meeting the needs of its clients in various industries, including automotive, aerospace, telecommunications, and medical devices.The company, headquartered in the United States, is known for its expertise in developing and manufacturing printed circuit boards (PCBs) and electronic components. With a team of highly skilled engineers and technicians, Pcb Engineering has built a reputation for delivering reliable and cutting-edge solutions to its clients.“We are thrilled to announce the expansion of our business operations,” said the CEO of Pcb Engineering. “As the demand for our products and services continues to grow, we are committed to investing in our infrastructure and expanding our capabilities to meet the needs of our clients. This expansion will allow us to increase our production capacity, improve our efficiency, and ultimately, better serve our customers.”In order to support its growth, Pcb Engineering has recently invested in state-of-the-art manufacturing equipment and technology. This investment will not only enhance the company’s production capabilities but also enable it to offer a wider range of engineering solutions to its clients.In addition to its investment in technology, Pcb Engineering is also expanding its workforce by hiring new talent across various functions, including engineering, manufacturing, quality control, and customer service. By bringing in new expertise and capabilities, the company aims to strengthen its position as a leading provider of engineering solutions in the industry.The expansion will also allow Pcb Engineering to further diversify its product offerings and enter new market segments. With a focus on continuous innovation, the company is committed to developing new and advanced engineering solutions that will address the evolving needs of its clients in different industries.Pcb Engineering’s commitment to quality and customer satisfaction has earned it a loyal and growing customer base. By expanding its business operations, the company aims to build on its strong reputation and further solidify its position as a trusted partner for engineering and manufacturing solutions.As part of its expansion plans, Pcb Engineering is also exploring opportunities to collaborate with strategic partners and suppliers to further enhance its capabilities and offerings. By leveraging the expertise and resources of its partners, the company aims to provide comprehensive and integrated solutions that meet the complex needs of its clients.With its expanded business operations, Pcb Engineering is well-positioned to capitalize on the growing demand for high-quality engineering solutions in the global market. The company’s dedication to innovation, quality, and customer satisfaction will continue to drive its growth and success in the industry.As Pcb Engineering continues to expand its operations, the company remains committed to upholding the highest standards of engineering excellence and customer service. With a focus on continuous improvement and innovation, the company is well-prepared to meet the evolving needs of its clients and deliver value-added solutions that drive their success.The expansion of Pcb Engineering’s business operations marks an exciting new chapter for the company as it seeks to further strengthen its position as a leading provider of engineering and manufacturing solutions globally. With its commitment to quality, innovation, and customer satisfaction, Pcb Engineering is poised for continued growth and success in the years to come.About Pcb EngineeringPcb Engineering is a leading engineering and manufacturing company that specializes in developing and manufacturing printed circuit boards and electronic components for various industries. With a focus on quality, innovation, and customer satisfaction, the company has built a strong reputation for delivering reliable and cutting-edge solutions to its clients. Headquartered in the United States, Pcb Engineering is committed to meeting the diverse needs of its customers by providing comprehensive and integrated engineering solutions.

High-quality SMD Chip Inductor for Electronic Devices - Everything You Need to Know

Smd chip inductors are essential components used in a wide range of electronic devices, including smartphones, tablets, computers, and many other consumer electronics. These inductors play a crucial role in the performance and efficiency of electronic circuits, making them a vital part of the electronics industry.One company that has been at the forefront of producing high-quality Smd chip inductors is [Company Name]. With a strong focus on innovation and a commitment to delivering top-notch products, [Company Name] has established itself as a leading supplier of Smd chip inductors in the global market.[Company Name] was founded [X years ago] and has since become a trusted name in the electronics industry. The company's dedication to research and development has led to the creation of a diverse range of Smd chip inductors that cater to the demands of various electronic applications. From high-frequency inductors to power inductors, [Company Name] has a comprehensive product portfolio to meet the needs of its customers.In addition to its broad product range, [Company Name] prides itself on its state-of-the-art manufacturing facilities and stringent quality control measures. These factors enable the company to consistently produce Smd chip inductors that meet the highest industry standards and exceed customer expectations. By prioritizing quality and reliability, [Company Name] has built a reputation for excellence in the electronics market.Furthermore, [Company Name] places a strong emphasis on customer satisfaction and strives to provide exceptional service to its clients. The company's team of experienced professionals is dedicated to offering technical support and guidance to customers, ensuring that they find the right Smd chip inductors for their specific needs. This commitment to customer service has helped [Company Name] foster long-lasting relationships with clients around the world.In recent news, [Company Name] has announced the release of a new line of Smd chip inductors that are set to raise the bar in terms of performance and efficiency. These innovative inductors have been designed to meet the evolving demands of the electronics industry and provide superior reliability in a compact form factor. By leveraging the latest technologies and materials, [Company Name] aims to further solidify its position as a leading provider of Smd chip inductors.The new line of Smd chip inductors from [Company Name] is expected to offer improved characteristics such as higher inductance, lower resistance, and better thermal stability. These enhancements will enable electronic device manufacturers to achieve higher levels of performance and energy efficiency in their products. With the demand for smaller, faster, and more power-efficient electronics on the rise, these advanced inductors are poised to make a significant impact in the industry."We are excited to introduce our latest Smd chip inductors, which showcase our ongoing commitment to technological advancement and customer satisfaction," said [Spokesperson] of [Company Name]. "We believe that these new inductors will empower our customers to create cutting-edge electronic devices that deliver exceptional performance and reliability."The release of the new line of Smd chip inductors represents another milestone for [Company Name], as it continues to push the boundaries of innovation in the electronics industry. As the demand for high-quality Smd chip inductors continues to grow, [Company Name] remains at the forefront, providing superior products and exceptional service to its global customer base. With a solid track record of success and a forward-looking approach, [Company Name] is poised to maintain its position as a leader in the market for years to come.

Key Steps for Successful Surface Mount Assembly Process

Today, we are excited to announce that our company, a leading provider of electronic manufacturing services, has integrated an advanced Surface Mount Assembly Process into our production capabilities. This cutting-edge technology will enable us to deliver high-quality and cost-effective electronic assemblies to our customers across a variety of industries.Our Surface Mount Assembly Process is a crucial part of our overall electronic manufacturing services. This process allows us to mount electronic components directly onto the surface of printed circuit boards, as opposed to through-hole mounting, which requires drilling holes in the circuit board for component leads to pass through. This method offers several advantages, including smaller component sizes, higher component density, and improved electrical performance.Incorporating this advanced assembly process into our manufacturing capabilities is a testament to our commitment to staying at the forefront of technological advancements in electronic manufacturing. We understand the importance of continuously improving our processes and investing in state-of-the-art equipment to meet the evolving needs of our customers and the industry as a whole.Our company has a long-standing reputation for delivering high-quality electronic assemblies, and the addition of the Surface Mount Assembly Process further solidifies our position as a reliable and innovative partner for electronic manufacturing needs. With this new capability, we are equipped to handle complex and high-volume production requirements while maintaining the highest standards of quality and efficiency.We are dedicated to providing comprehensive electronic manufacturing services to a wide range of industries, including aerospace, automotive, telecommunications, medical devices, and more. Our expertise in Surface Mount Assembly, combined with our extensive experience in electronic design, prototyping, and testing, positions us as a trusted partner for companies seeking reliable and cost-effective manufacturing solutions.Furthermore, our commitment to quality and reliability is reflected in our adherence to industry standards and certifications. Our manufacturing facilities are equipped with the latest technology and staffed by highly skilled professionals who undergo continuous training to ensure that our processes meet the stringent requirements of the industry.With the integration of the Surface Mount Assembly Process, we are able to offer our customers streamlined production processes, reduced manufacturing costs, and faster time-to-market for their electronic products. This is particularly advantageous for industries with rapidly changing technological landscapes and increasing demand for compact and high-performance electronic devices.In addition to enhancing our manufacturing capabilities, the Surface Mount Assembly Process aligns with our efforts to embrace environmentally friendly practices. By minimizing material waste and energy consumption, we are contributing to sustainable and responsible manufacturing processes, which is an important consideration for many of our customers and the industry as a whole.To celebrate the integration of the Surface Mount Assembly Process, we are offering special promotions for new and existing customers who are looking to take advantage of our enhanced capabilities. We invite companies seeking electronic manufacturing solutions to get in touch with us to learn more about how our Surface Mount Assembly Process can benefit their specific requirements.In conclusion, the integration of the Surface Mount Assembly Process into our electronic manufacturing services represents a significant milestone for our company. This advanced technology, combined with our dedication to quality, reliability, and environmental sustainability, further strengthens our position as a leading provider of electronic manufacturing solutions. We are excited to continue serving the needs of our customers with innovative and cost-effective electronic assembly capabilities.

The Future of Smart Manufacturing: The Impact of IoT Technology on Production

In today's fast-paced and ever-evolving world, the manufacturing industry is constantly looking for ways to improve production efficiency, reduce costs, and deliver superior quality products to meet the demands of the market. The emergence of Industry 4.0 and the Internet of Things (IoT) has revolutionized the way manufacturing companies operate, bringing about a new era of smart, connected, and automated production processes.With the integration of IoT in manufacturing, companies are able to gather and analyze real-time data from their production equipment, allowing for better decision-making, predictive maintenance, and overall optimization of the manufacturing process. This technology has the potential to transform traditional factories into smart factories, where machines, systems, and products communicate with each other to improve operational efficiency and drive innovation.One company that has been at the forefront of IoT manufacturing is {}. specializes in providing cutting-edge IoT solutions for manufacturers to help them optimize their production processes and achieve higher levels of productivity and quality. With a strong focus on innovation and customer satisfaction, {} has established itself as a leading provider of IoT manufacturing solutions, partnering with manufacturers across various industries to help them embrace the digital transformation of their operations.{}'s IoT manufacturing solutions are tailored to meet the specific needs of each customer, providing a seamless integration of IoT technologies into their existing production systems. By leveraging the power of IoT, manufacturers are able to monitor and control their production processes in real-time, identify potential issues before they escalate, and make informed decisions to improve overall efficiency and reduce downtime.One of the key features of {}'s IoT manufacturing solutions is the use of advanced sensors and connected devices to collect and transmit data from the factory floor to a centralized system. This real-time data can then be analyzed using sophisticated analytics tools to gain insights into production performance, equipment utilization, and quality control. By harnessing this wealth of information, manufacturers can proactively address production inefficiencies, optimize resource utilization, and continuously improve their processes to stay ahead of the competition.Furthermore, {}'s IoT manufacturing solutions enable manufacturers to implement predictive maintenance strategies, where equipment health and performance data are used to predict potential failures and schedule maintenance activities accordingly. This proactive approach to maintenance not only helps to prevent costly downtime but also extends the lifespan of equipment, reducing overall maintenance costs and improving the reliability of production systems.Another significant benefit of {}'s IoT manufacturing solutions is the ability to enable remote monitoring and control of production processes. With the use of connected devices and cloud-based platforms, manufacturers can access real-time production data from anywhere, allowing them to monitor and adjust their processes on the go. This level of flexibility and control is essential for manufacturers to adapt to changing market demands, address production issues promptly, and make data-driven decisions to optimize their operations.As manufacturers continue to embrace the digital transformation of their operations, {} remains committed to empowering them with the latest IoT manufacturing technologies and expertise. By collaborating closely with manufacturers, understanding their unique challenges, and delivering tailored IoT solutions, {} is driving the adoption of Industry 4.0 principles within the manufacturing industry, helping companies to unlock new levels of efficiency, productivity, and competitiveness.In conclusion, the integration of IoT in manufacturing has disrupted traditional production processes, paving the way for smart factories that are equipped with advanced technologies to drive operational excellence. With {}'s leading IoT manufacturing solutions, manufacturers are able to harness the power of real-time data, predictive analytics, and remote monitoring to transform their operations, achieve higher levels of efficiency, and stay ahead in today's highly competitive market. As the manufacturing industry continues to evolve, companies like {} will play a pivotal role in helping manufacturers navigate the complexities of digital transformation and realize the full potential of IoT in manufacturing.

High-Quality Printed Control Board for Manufactured goods

Printed Control Board (PCB) is a vital component in the electronics industry, playing a crucial role in the functioning of various electronic devices and equipment. These boards are a crucial part of a wide range of products including smartphones, tablets, computers, medical equipment, automotive systems, and much more. As the demand for electronic devices continues to grow, the need for high-quality PCBs is also on the rise.With this increasing demand, companies like {} are taking the lead in manufacturing top-notch PCBs to cater to the needs of various industries. {} is a leading provider of advanced PCB solutions, offering a wide range of products tailored to the specific needs of their clients. With a commitment to quality, innovation, and customer satisfaction, {} has established itself as a key player in the electronics industry.The company prides itself on its state-of-the-art manufacturing facilities that are equipped with the latest technology and machinery to produce high-quality PCBs. {} offers a wide range of PCB products including single-sided PCBs, double-sided PCBs, multi-layer PCBs, flexible PCBs, and rigid-flex PCBs. Their diverse product range allows them to cater to the needs of different industries and applications, ensuring that they can provide customized solutions to their clients.In addition to their extensive product range, {} also offers design and engineering services to assist their clients in developing custom PCB solutions. Their team of experienced engineers and designers work closely with clients to understand their specific requirements and provide them with tailored solutions that meet their exact needs. This collaborative approach has helped {} build strong and lasting relationships with their clients, establishing them as a trusted partner in the electronics industry.Furthermore, {} is dedicated to ensuring the quality and reliability of their products. They adhere to strict quality control measures throughout the manufacturing process to guarantee that each PCB meets the highest standards. This commitment to quality has earned {} various certifications and accreditations, further solidifying their reputation as a reliable and trustworthy PCB manufacturer.As a company focused on innovation and advancement, {} continues to invest in research and development to drive continuous improvement in their products and services. They keep abreast of the latest technological advancements and industry trends to ensure that they can offer cutting-edge solutions to their clients. This forward-thinking approach has allowed {} to stay ahead of the competition and maintain its position as a leader in the PCB manufacturing industry.With a strong foundation built on quality, innovation, and customer-centric approach, {} is well-positioned to meet the growing demand for PCBs in the electronics industry. Their commitment to excellence and dedication to customer satisfaction make them a preferred choice for businesses seeking reliable and high-quality PCB solutions.In conclusion, Printed Control Boards are an indispensable part of the electronics industry, and companies like {} are instrumental in meeting the increasing demand for top-quality PCBs. With a focus on quality, innovation, and customer satisfaction, {} has established itself as a leading provider of advanced PCB solutions, offering a diverse range of products and services to cater to the specific needs of their clients. As the electronics industry continues to evolve, {} is well-equipped to meet the challenges and opportunities that lie ahead, maintaining its position as a key player in the industry.

How to Conduct a Continuity Light Test for Effective Functionality

Continuity Light Test, a new and innovative product in electrical testing, is revolutionizing the way electrical systems are tested and maintained. This ground-breaking technology is the first of its kind, using advanced algorithms and precise measurements to quickly and accurately assess the continuity of electrical circuits. The Continuity Light Test is a game-changer in the electrical industry, providing a safe, efficient, and reliable method for testing electrical systems.One of the key features of the Continuity Light Test is its ability to test the continuity of electrical circuits without the need for physical contact with the circuit itself. This is achieved through advanced electromagnetic technology, which is capable of detecting the presence or absence of conductivity in the circuit without the need for direct contact. This eliminates the need for traditional testing methods, which often require the use of probes or other physical testing equipment that can be time-consuming and potentially dangerous.In addition to its non-contact testing capabilities, the Continuity Light Test also boasts an impressive level of accuracy and precision. Its advanced algorithms are able to analyze the electrical circuit and provide a clear indication of whether continuity is present or not. This level of accuracy is crucial in ensuring the safety and reliability of electrical systems, as any faults or breaks in continuity can lead to potentially dangerous electrical malfunctions.Furthermore, the Continuity Light Test is designed to be extremely user-friendly, making it accessible to electrical professionals of all levels of experience. The device is equipped with a clear and intuitive interface, making it easy to understand and operate. This allows for quick and efficient testing of electrical circuits, saving time and reducing the risk of errors or inaccuracies in testing.The Continuity Light Test is also designed with durability and reliability in mind. Its robust construction ensures that it can withstand the rigors of daily use in a variety of work environments, making it a long-lasting and dependable tool for electrical testing.In addition to its groundbreaking technology and user-friendly design, the Continuity Light Test has also garnered praise for its commitment to safety. The device is engineered to meet the highest safety standards, with built-in features to protect against electrical hazards and ensure the safety of the user during testing.{Company name}'s Continuity Light Test is changing the game in electrical testing, providing a safe, efficient, and reliable solution for testing the continuity of electrical circuits. With its non-contact testing capabilities, advanced algorithms, user-friendly design, and commitment to safety, the Continuity Light Test is quickly becoming the go-to choice for electrical professionals looking to ensure the safety and reliability of electrical systems.

Innovative Rigid Flex Assembly solutions for electronic devices

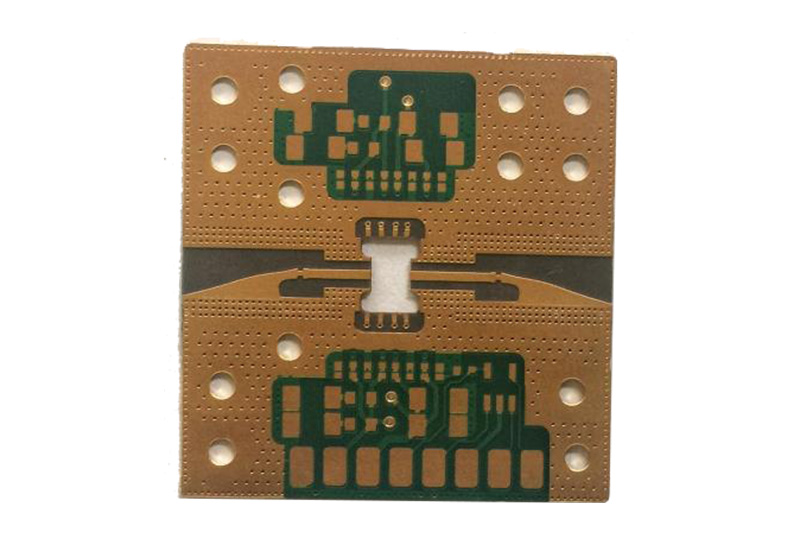

Rigid Flex Assembly is a process in which printed circuit boards (PCBs) are manufactured using a combination of both rigid and flexible materials. This innovative technology allows for increased durability and flexibility in the design and production of electronic products. As a leading provider of electronic manufacturing services, {} has been at the forefront of developing and implementing Rigid Flex Assembly solutions for a wide range of industries. With its state-of-the-art facilities and dedicated team of engineers, the company has earned a reputation for delivering high-quality, reliable, and cost-effective solutions to its clients.The Rigid Flex Assembly process involves the integration of both rigid and flexible PCBs into a single, seamless unit. This allows for greater freedom in designing the layout of the PCB, as well as increased durability and reliability in the finished product. By combining rigid and flexible materials, {} is able to create PCBs that can conform to the shape of the device they are installed in, making them ideal for use in small, compact electronic devices.One of the key advantages of Rigid Flex Assembly is its ability to reduce the number of interconnects required in a device. By eliminating the need for multiple separate PCBs and connectors, the overall size and weight of the device can be reduced, while also improving reliability and reducing the risk of failure. This makes Rigid Flex Assembly an ideal choice for use in products where space and weight are at a premium, such as in the aerospace, medical, and automotive industries.In addition to its technical advantages, Rigid Flex Assembly also offers cost savings for manufacturers. By reducing the number of individual components and simplifying the assembly process, {} is able to lower production costs and shorten lead times for its clients. This allows for quicker time-to-market for new products, as well as improved competitiveness in the marketplace.With its extensive experience in the field of electronic manufacturing, {} has developed a deep understanding of the specific needs and requirements of its clients. The company works closely with its customers to develop customized Rigid Flex Assembly solutions that are tailored to their unique applications and specifications. By providing a comprehensive suite of design, engineering, and manufacturing services, {} is able to deliver turnkey solutions that meet the highest standards of quality and reliability.As the demand for smaller, lighter, and more durable electronic products continues to grow, the use of Rigid Flex Assembly is expected to become increasingly prevalent across a wide range of industries. {} is well positioned to meet this demand, with its proven expertise and track record of success in delivering advanced electronic manufacturing solutions to its clients.In conclusion, Rigid Flex Assembly is a game-changing technology that offers numerous advantages for manufacturers of electronic products. By leveraging its expertise in this field, {} is able to provide its clients with innovative, cost-effective solutions that are tailored to their specific needs. With its commitment to quality, reliability, and customer satisfaction, {} is poised to remain a leader in the electronic manufacturing industry for years to come.