Top 5 Tips for Flex Circuit Assembly to Boost Efficiency and Quality

By:Admin

Flex Circuit Assembly is a leading provider of high-quality flex circuit assembly solutions. With over 20 years of experience in the industry, the company has built a strong reputation for delivering innovative and reliable products to its clients. Now, Flex Circuit Assembly is expanding its offerings to further revolutionize the electronics industry.

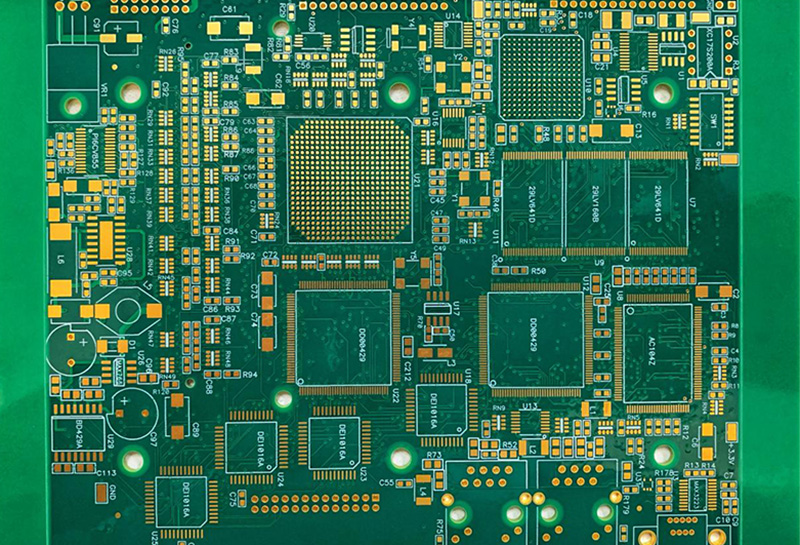

The company specializes in the design, manufacturing, and assembly of flexible printed circuit boards (FPCBs) and rigid-flex circuits. These products are used in a wide range of applications, including consumer electronics, medical devices, automotive systems, and aerospace technology. Flex Circuit Assembly's expertise in flex circuit assembly has made it a trusted partner for many leading companies in these industries.

With the expansion of its offerings, Flex Circuit Assembly is poised to take its capabilities to the next level. The company is investing in state-of-the-art equipment and technology to enhance its manufacturing processes and deliver even higher quality products to its customers. By leveraging advanced materials and manufacturing techniques, Flex Circuit Assembly aims to push the boundaries of what is possible in the electronics industry.

One of the key areas of focus for Flex Circuit Assembly is the development of flexible and wearable electronics. As the demand for smaller, lighter, and more flexible electronic devices continues to grow, the company is committed to meeting this need with its cutting-edge solutions. Flex Circuit Assembly's expertise in flex circuit assembly makes it well-positioned to lead the way in this emerging field.

In addition to its focus on flexible electronics, Flex Circuit Assembly is also expanding its capabilities in rigid-flex circuits. These products are becoming increasingly important in a wide range of industries, and the company is dedicated to meeting the growing demand for high-quality rigid-flex circuits. With its extensive experience and expertise, Flex Circuit Assembly is well-equipped to deliver custom solutions that meet the unique needs of its clients.

Furthermore, Flex Circuit Assembly is committed to sustainability and environmental responsibility. The company is actively seeking out eco-friendly materials and manufacturing processes that minimize waste and reduce its carbon footprint. By integrating sustainable practices into its operations, Flex Circuit Assembly is demonstrating its dedication to corporate social responsibility and making a positive impact on the environment.

Flex Circuit Assembly's expanded offerings are set to make a significant impact on the electronics industry. By delivering innovative and reliable products, the company is empowering its clients to develop cutting-edge devices and technologies. With its commitment to quality, sustainability, and continuous improvement, Flex Circuit Assembly is poised to revolutionize the way electronic products are designed and manufactured.

"We are excited to announce the expansion of our offerings at Flex Circuit Assembly," said [Company Spokesperson]. "With our focus on flexible and wearable electronics, as well as our dedication to sustainability, we are setting the stage for a new era in the electronics industry. We are committed to pushing the boundaries of what is possible and delivering the highest quality products to our clients."

As Flex Circuit Assembly continues to expand its capabilities and offerings, the company is positioned to play a pivotal role in shaping the future of the electronics industry. With its focus on innovation, sustainability, and quality, Flex Circuit Assembly is dedicated to driving positive change and creating new opportunities for its clients and partners.

Company News & Blog

How to Choose the Best Passive Income Opportunities

Passive Comp, a leading company in the field of passive components, has been making waves in the industry with its innovative and high-quality products. Since its inception, the company has strived to provide customers with the best passive components on the market, and it has consistently delivered on this promise.The company has a wide range of passive components, including resistors, capacitors, inductors, and more. These components are essential in electronic circuits, and Passive Comp has made it its mission to produce components that are reliable, durable, and efficient. The company's commitment to quality has earned it a stellar reputation in the industry, and it is trusted by countless customers around the world.Passive Comp's success can be attributed to several key factors. Firstly, the company's dedication to research and development has allowed it to stay ahead of the curve when it comes to technological advancements. This has enabled them to consistently produce components that meet the ever-evolving needs of the industry. Additionally, the company's state-of-the-art manufacturing facilities and stringent quality control measures ensure that every component that leaves their factory meets the highest standards.One of the company's flagship products is its range of resistors. These components are widely used in electronic circuits to limit current flow, and Passive Comp's resistors are renowned for their precision and reliability. The company offers a variety of resistor types, including film resistors, wirewound resistors, and more, catering to the diverse needs of its customers.In addition to resistors, Passive Comp also offers a wide range of capacitors. Capacitors are used to store and release electrical energy, and the company's capacitors are designed to offer excellent performance and longevity. Whether it's ceramic, electrolytic, or tantalum capacitors, customers can rely on Passive Comp to deliver top-quality products that meet their requirements.Furthermore, Passive Comp's range of inductors has also been well-received in the industry. Inductors are essential in electronic circuits for storing energy in the form of a magnetic field, and the company's inductors are known for their reliability and efficiency. With a variety of inductor types, including fixed inductors, variable inductors, and more, the company offers solutions for various applications.One of the company's key strengths is its ability to customize components according to customer specifications. This flexibility has allowed Passive Comp to cater to the unique needs of different industries and applications, earning the trust and loyalty of its customers. Whether it's a specific resistance value for a resistor or a particular capacitance for a capacitor, the company's engineering team works closely with customers to deliver components that precisely meet their requirements.Aside from its product offerings, Passive Comp is also committed to sustainability and environmental responsibility. The company adheres to strict environmental regulations and actively seeks to minimize its environmental impact through efficient manufacturing processes and waste reduction initiatives. This dedication to sustainability has not only earned the company accolades but has also positioned it as a responsible and ethical industry leader.Looking to the future, Passive Comp is focused on further expanding its product range and continuing to innovate in the field of passive components. With a strong emphasis on research and development, the company is constantly exploring new technologies and materials to improve its products and stay ahead of the competition. Additionally, as the demand for electronic components continues to grow, Passive Comp is committed to scaling its production capabilities to meet customer needs.In conclusion, Passive Comp has established itself as a powerhouse in the field of passive components. With its unwavering commitment to quality, technological innovation, and customer satisfaction, the company has earned the trust and respect of the industry. As it continues to push boundaries and set new standards, Passive Comp is poised to remain a top player in the market for years to come.

Latest News: PCB Converter Simplifies Content Conversion

At the forefront of innovation in the electronics industry, a leading company in the field of printed circuit board (PCB) manufacturing has announced the launch of a new content converter PCB. This state-of-the-art technology is set to revolutionize the way data is transmitted and processed, opening up possibilities for faster and more efficient communication in a wide range of electronic devices.With a focus on delivering high-quality and reliable PCB solutions, the company has built a strong reputation for its commitment to innovation and excellence. Their expertise in the design and manufacturing of PCBs has earned them a prominent position in the market, serving a diverse clientele across various industries.The new content converter PCB is designed to enhance the functionality and performance of electronic devices by efficiently converting data from one format to another. This innovative technology will enable seamless integration of different communication protocols, making it ideal for applications that require the exchange of data in various formats.One of the key features of the new content converter PCB is its ability to facilitate the conversion of digital signals, analog signals, and other data formats with minimal latency and maximum reliability. This will significantly benefit industries such as telecommunications, automotive, consumer electronics, and industrial automation, where efficient data conversion is critical for smooth and uninterrupted operations.Furthermore, the company's dedication to quality and precision is evident in the meticulous design and manufacturing process of the content converter PCB. With a focus on adhering to industry standards and best practices, the company ensures that their PCBs are of the highest quality, reliability, and performance.In addition to the technical capabilities of the new content converter PCB, the company also prides itself on providing exceptional customer support and technical assistance to their clients. Their team of experienced engineers and technicians are readily available to provide guidance and support throughout the entire integration process, ensuring that the content converter PCB meets the specific requirements of each application.The launch of the new content converter PCB is a testament to the company's ongoing commitment to innovation and advancement in the electronics industry. By combining their technical expertise with a dedication to delivering cutting-edge solutions, the company is poised to make a significant impact on the market and empower their clients with the latest technology.In conclusion, the introduction of the new content converter PCB represents a significant milestone for the company and the industry as a whole. With its advanced capabilities, precision engineering, and unwavering commitment to quality, the company is set to further solidify its position as a leader in PCB manufacturing and technology. As the demand for efficient data conversion solutions continues to grow, the new content converter PCB is poised to become a cornerstone technology for a wide range of electronic applications, driving innovation and progress in the ever-evolving electronics industry.

Ultimate Guide to Understanding Voltage Drop with a Multimeter

In today's fast-paced world, it is crucial to have the right tools to ensure efficiency and accuracy in various tasks. For professionals and hobbyists working with electrical circuits, a high-quality multimeter is an essential tool for measuring voltage, current, and resistance. With the recent release of the new Multimeter Voltage Drop from {}, individuals can now expect even greater accuracy and reliability in their voltage measurement needs.{}, a leading manufacturer of electrical testing equipment, has been at the forefront of innovation in the industry for over 50 years. The company's commitment to quality and precision has earned them a reputation as a trusted provider of electrical testing solutions. With a focus on meeting the needs of professionals and enthusiasts alike, {} continues to develop cutting-edge products that set the standard for performance and reliability.The Multimeter Voltage Drop is the latest addition to {}'s extensive line of multimeters, and it promises to deliver unmatched accuracy in voltage measurement. The device features a high-precision voltage measurement system that provides reliable readings for both AC and DC voltage, making it suitable for a wide range of applications. Additionally, the multimeter is equipped with advanced safety features to ensure user protection while working with high voltages.One of the key features of the Multimeter Voltage Drop is its ability to measure voltage drop across various components in an electrical circuit. This functionality is particularly useful for troubleshooting and diagnosing issues in both automotive and industrial electrical systems. By accurately measuring voltage drop, technicians can quickly identify areas of concern and address potential problems before they escalate.Furthermore, the Multimeter Voltage Drop from {} is designed with user convenience in mind. The device boasts a large, easy-to-read display, allowing users to view readings clearly in any lighting conditions. Additionally, the multimeter is ergonomically designed for comfort and ease of use, making it suitable for extended periods of operation.In addition to its high-precision measurement capabilities, the Multimeter Voltage Drop also offers a range of other useful functions. These include the ability to measure current, resistance, and continuity, making it a versatile tool for various electrical testing needs. Furthermore, the multimeter is designed to withstand the rigors of professional use, with a rugged construction that ensures durability in demanding work environments.With the release of the Multimeter Voltage Drop, {} continues to demonstrate its commitment to quality and innovation in the field of electrical testing equipment. By combining advanced measurement capabilities with user-friendly design, the company has once again raised the bar for multimeter performance.As professionals and enthusiasts seek reliable and accurate tools for electrical testing, the Multimeter Voltage Drop from {} stands out as a top choice. With its precision measurement capabilities, safety features, and user-friendly design, this multimeter is poised to become an indispensable tool for anyone working with electrical circuits.In conclusion, the release of the Multimeter Voltage Drop from {} represents a significant advancement in the field of electrical testing equipment. With its high-precision measurement capabilities, advanced safety features, and user-friendly design, this multimeter sets a new standard for accuracy and reliability in voltage measurement. As {} continues to lead the way in innovation, professionals and enthusiasts can rely on the company to provide cutting-edge solutions for their electrical testing needs.

Essential Tips for Using a PCB Stencil for Manufacturing

PCB Company Introduces Innovative Stencil for Enhanced PCB ManufacturingIn the world of PCB (Printed Circuit Board) manufacturing, precision and accuracy are crucial. With the advancement of technology, the demand for high-quality PCB stencils has increased significantly. To meet this demand, {Company Name}, a leading PCB manufacturing company, has introduced an innovative stencil for PCB use. This new stencil is designed to provide enhanced precision and efficiency in the PCB manufacturing process.The new stencil is a result of extensive research and development efforts by the {Company Name} team. It is created using high-quality materials and advanced manufacturing techniques to ensure superior performance. The stencil is designed to accurately transfer solder paste onto the PCB, enabling precise placement of surface mount components during the assembly process.One of the key features of the new stencil is its durability. It is made from a highly durable material that can withstand the rigors of the PCB manufacturing process, including multiple uses and cleaning cycles. This durability ensures that the stencil maintains its precision and performance over time, resulting in consistent high-quality PCB assemblies.In addition to durability, the new stencil also offers improved accuracy. Its advanced design and manufacturing process result in fine detail and precise openings, allowing for precise and consistent solder paste deposition. This level of accuracy is essential for the assembly of increasingly complex and miniaturized electronic components.Moreover, the new stencil is designed for ease of use. It is compatible with various PCB manufacturing equipment and processes, making it easy to integrate into existing manufacturing workflows. This compatibility ensures a smooth transition for PCB manufacturers who choose to adopt the new stencil for their operations.{Company Name} is renowned for its commitment to innovation and quality in PCB manufacturing. With the introduction of this new stencil, the company aims to further solidify its position as a leader in the industry. The innovative features of the new stencil demonstrate {Company Name}'s dedication to addressing the evolving needs of PCB manufacturers and supporting them in achieving outstanding results.In a statement, {Spokesperson Name}, {Title} at {Company Name}, expressed enthusiasm about the new stencil and its potential impact on the industry. "We are thrilled to introduce this advanced stencil for PCB use. It represents our ongoing efforts to push the boundaries of innovation in PCB manufacturing. We believe that this stencil will empower our customers to achieve new levels of precision and efficiency in their manufacturing processes."The introduction of the new stencil has already generated significant interest within the PCB manufacturing community. Several industry experts have lauded {Company Name} for its commitment to advancing the field of PCB manufacturing and providing practical solutions to industry challenges.In conclusion, the introduction of the innovative stencil for PCB use by {Company Name} represents a significant development in the PCB manufacturing industry. The new stencil's durability, accuracy, and ease of use are poised to make a positive impact on the efficiency and quality of PCB assembly processes. As the demand for high-quality PCBs continues to grow, {Company Name} is well-positioned to meet the needs of PCB manufacturers with its cutting-edge solutions.

Efficient Turnaround Time for PCBA Services

Fast Turnaround PCBA: A Game Changer in Electronic ManufacturingIn today's fast-paced world, the demand for electronic devices is constantly growing. From smartphones to medical devices, the need for electronic components is ever-increasing. With such high demand, there is also a greater need for quick and efficient electronic manufacturing processes. This is where Fast Turnaround PCBA comes into play.Fast Turnaround PCBA, which stands for Printed Circuit Board Assembly, is a revolutionary method in electronic manufacturing that allows for quick turnaround times without compromising on quality. By leveraging advanced technologies and streamlined processes, companies are now able to produce high-quality electronic components in a fraction of the time it used to take.One company that has been at the forefront of this technological advancement is {Company Name}. With their state-of-the-art facilities and cutting-edge equipment, {Company Name} has been able to deliver fast and reliable PCBA services to their clients, ensuring that they stay ahead of the competition.Established in {year}, {Company Name} has quickly become a trusted name in the electronic manufacturing industry. With a strong focus on innovation and customer satisfaction, they have continuously pushed the boundaries of what is possible in electronic manufacturing. Their dedicated team of engineers and technicians are committed to providing the best-in-class solutions to their clients, and Fast Turnaround PCBA is just one of the many ways they have been able to achieve this.Fast Turnaround PCBA has completely transformed the way electronic components are manufactured. In the past, the traditional PCBA process could take weeks or even months to complete. This not only delayed the time to market for new products but also increased the risk of obsolescence. With Fast Turnaround PCBA, however, companies are now able to get their electronic components produced in a matter of days, significantly reducing the time it takes to bring new products to market.The key to Fast Turnaround PCBA lies in the optimization of the manufacturing process. By utilizing advanced automation and robotics, {Company Name} has been able to streamline their production line, effectively reducing the time it takes to assemble and test electronic components. This not only allows for faster turnaround times but also ensures that the quality of the products remains consistently high.Another benefit of Fast Turnaround PCBA is its ability to support rapid prototyping and small batch production. In the past, companies would have to wait for weeks before they could receive a prototype of a new electronic device. With Fast Turnaround PCBA, however, companies can now get their prototypes produced in a matter of days, allowing them to quickly iterate and test new designs. This has been a game-changer for companies looking to stay ahead of the competition and bring innovative products to market faster.Furthermore, Fast Turnaround PCBA has also been instrumental in reducing the lead times for production runs. With the traditional PCBA process, companies would have to wait for weeks before they could receive their production runs. This often led to delays in product launches and missed opportunities. With Fast Turnaround PCBA, companies can now receive their production runs in a fraction of the time, allowing them to better meet customer demand and capitalize on market trends.As the demand for electronic devices continues to grow, the need for Fast Turnaround PCBA will only become more crucial. Companies like {Company Name} are leading the way in revolutionizing the electronic manufacturing industry, and their commitment to innovation and excellence is setting a new standard for the industry. With Fast Turnaround PCBA, companies can now expect faster lead times, higher quality products, and a competitive edge in the market.In conclusion, Fast Turnaround PCBA has been a game-changer in electronic manufacturing, and companies like {Company Name} are at the forefront of this technological advancement. With their dedication to innovation and customer satisfaction, {Company Name} has been able to deliver fast and reliable PCBA services to their clients, setting a new standard for the industry. As the demand for electronic devices continues to grow, the need for Fast Turnaround PCBA will only become more crucial, and companies can rely on {Company Name} to provide the best-in-class solutions for their electronic manufacturing needs.

Top Components for SMD Assembly in Electronics Manufacturing

SMD Components Are Revamping Electronics IndustryThe electronics industry has seen a significant revolution in recent years, thanks to the rapid advancements in surface mount device (SMD) components. These tiny electronic components have revolutionized the design and manufacturing processes of electronic devices, making them smaller, lighter, and more efficient. As a leading provider of SMD components, {company name} has played a pivotal role in this revolution.{company name} is a global leader in the production and distribution of SMD components for various electronic applications. Since its inception, the company has been at the forefront of innovation, constantly developing new and improved SMD components to meet the ever-evolving demands of the electronics industry.One of the key advantages of SMD components is their compact size, which allows for more efficient use of space on circuit boards. This, in turn, has enabled the development of smaller and more portable electronic devices, such as smartphones, tablets, and wearable technology. Additionally, the lightweight nature of SMD components has contributed to the overall reduction in the weight of electronic devices, making them more convenient for everyday use.Furthermore, SMD components offer superior thermal performance and energy efficiency, resulting in electronic devices that consume less power and produce less heat. This has not only extended the battery life of portable devices but also contributed to the overall sustainability of electronic products.In addition to these benefits, SMD components have also simplified the manufacturing process of electronic devices. Their compatibility with automated assembly processes has led to increased production efficiency and reduced manufacturing costs. This has enabled manufacturers to meet the growing demand for electronic devices while maintaining high-quality standards.{company name} has been instrumental in driving these advancements in SMD technology. The company's commitment to research and development has led to the creation of innovative SMD components that have set new industry standards. By constantly pushing the boundaries of what is possible with SMD technology, {company name} has earned a reputation for delivering high-quality, reliable components that meet the diverse needs of its customers.One of the flagship products of {company name} is the cutting-edge SMD resistor series, which offers unparalleled performance and reliability. These resistors are designed to meet the stringent requirements of modern electronic devices, providing stable and accurate resistance values in a compact form factor. With a focus on precision engineering and quality control, {company name} has established itself as a trusted supplier of SMD resistors for a wide range of applications, from consumer electronics to industrial equipment.Moreover, {company name} offers a comprehensive range of SMD capacitors, inductors, and diodes, catering to the diverse needs of its customers. These components are designed to deliver exceptional electrical performance, ensuring the optimal functioning of electronic circuits in various applications. With a strong emphasis on technological innovation and product reliability, {company name} has become a preferred choice for electronic manufacturers worldwide.As the demand for smaller, faster, and more efficient electronic devices continues to grow, the role of SMD components in shaping the future of the electronics industry becomes increasingly important. {company name} remains committed to driving innovation in SMD technology, providing its customers with the tools they need to stay ahead in a rapidly evolving market.In conclusion, SMD components have revolutionized the electronics industry, enabling the design and manufacturing of smaller, lighter, and more efficient electronic devices. {company name} stands at the forefront of this revolution, driving innovation and setting new industry standards with its comprehensive range of high-quality SMD components. As the demand for advanced electronic devices continues to grow, {company name} remains dedicated to delivering cutting-edge SMD solutions that redefine the possibilities of modern electronics.

High-Quality Speaker Inductor Coils: A Comprehensive Guide

Speaker Inductor Coil Technology: Enhancing Sound QualityThe demand for high-quality audio products has been on the rise as people are becoming more conscious about their entertainment experience. Companies are consistently looking for ways to innovate their products and enhance the sound quality to meet the growing demands of the market. One such innovation is the use of speaker inductor coil technology, which has been gaining popularity in the audio industry.Speaker inductor coil technology is a crucial component in the design and production of high-quality speakers. It plays a significant role in enhancing the sound quality and overall performance of speakers. As a result, many leading audio companies, including {Company Name}, have incorporated this technology into their products to provide an exceptional audio experience to their customers.{Company Name} has been a pioneer in the audio industry, known for its commitment to delivering superior sound solutions to its customers. The company has been at the forefront of technological advancements, and its integration of speaker inductor coil technology is a testament to its dedication to innovation. By incorporating this technology into their speakers, {Company Name} has been able to set itself apart from its competitors and establish a strong presence in the market.The speaker inductor coil serves as a critical component in the audio system, playing a crucial role in producing high-quality sound. It is responsible for filtering out unnecessary frequencies and ensuring that the speaker produces clear and crisp sound. This technology allows for better control and accuracy in sound reproduction, resulting in an immersive and detailed audio experience for the listeners.One of the key advantages of speaker inductor coil technology is its ability to improve the overall efficiency of speakers. By reducing distortion and minimizing power loss, this technology enables speakers to operate at their optimal performance levels, thus delivering a more robust and dynamic sound output. As a result, customers can enjoy a more immersive and enjoyable listening experience, whether it be for music, movies, or gaming.Furthermore, the integration of speaker inductor coil technology has allowed {Company Name} to expand its product offerings and cater to a wider range of customers. By incorporating this technology into their speakers, the company has been able to develop a diverse portfolio of high-quality audio products that cater to the varying needs and preferences of consumers. Whether it's for home audio systems, professional studio monitors, or portable Bluetooth speakers, {Company Name} has been able to deliver exceptional sound quality across its product range.In addition to enhancing sound quality, speaker inductor coil technology also contributes to the durability and longevity of speakers. By ensuring that the speaker operates at its optimum level, this technology minimizes the risk of damage to the speaker's components, thus prolonging its lifespan. This has been a key factor in the success of {Company Name}, as customers have come to trust the reliability and durability of their products.Moving forward, {Company Name} remains committed to further advancing its audio technologies and raising the bar for sound quality in the industry. With the integration of speaker inductor coil technology, the company continues to set new standards for audio excellence and provide customers with unparalleled listening experiences.In conclusion, the integration of speaker inductor coil technology has played a pivotal role in enhancing the sound quality and performance of speakers. {Company Name} has been at the forefront of this innovation, leveraging this technology to deliver high-quality audio products to its customers. As the demand for premium audio solutions continues to grow, the role of speaker inductor coil technology in shaping the future of the audio industry cannot be overstated.

Ultimate Guide to Understanding Rigid Flex PCB Technology

In the world of technology and electronics, innovation is key, and the latest breakthrough in PCB technology is the development of rigid-flex PCBs. These advanced circuit boards offer a unique combination of flexibility and durability, making them ideal for a wide range of applications. One company at the forefront of this cutting-edge technology is {Company}, a leading manufacturer of electronic components and systems.{Company} has been a pioneer in the development of rigid-flex PCBs, and their latest offering is set to revolutionize the industry. These innovative circuit boards are designed to provide the best of both worlds – the flexibility of a traditional flex PCB, combined with the rigidity of a standard rigid PCB. This unique combination allows for greater design flexibility and a wider range of applications, making them the ideal choice for a variety of electronic devices.One of the key advantages of rigid-flex PCBs is their durability and reliability. Unlike traditional PCBs, which are prone to damage from bending and flexing, rigid-flex PCBs are designed to withstand the rigors of constant movement and high-stress environments. This makes them the perfect choice for applications where reliability is paramount, such as medical devices, aerospace systems, and industrial equipment.In addition to their durability, rigid-flex PCBs also offer a number of practical benefits. Their unique design allows for more efficient use of space, making them ideal for compact electronic devices where space is at a premium. This can lead to cost savings and improved performance, making rigid-flex PCBs a smart choice for manufacturers looking to optimize their designs.{Company}’s commitment to innovation and excellence has made them a leader in the development of rigid-flex PCBs. With a dedicated team of engineers and technicians, they have been able to push the boundaries of what is possible in PCB technology, bringing cutting-edge solutions to their customers around the world.The company’s state-of-the-art manufacturing facilities are equipped with the latest technology and equipment, allowing them to produce rigid-flex PCBs to the highest standards of quality and precision. Their focus on continuous improvement and investment in research and development has allowed them to stay ahead of the competition and provide their customers with the most advanced solutions on the market.{Company}’s rigid-flex PCBs have already been met with great enthusiasm from their customers, who are excited about the possibilities that this innovative technology offers. Whether it’s for a medical device, a consumer electronics product, or an industrial application, {Company}’s rigid-flex PCBs are sure to make a lasting impact.Looking to the future, {Company} is committed to continuing their work at the forefront of PCB technology, constantly pushing the boundaries of what is possible and bringing new, exciting solutions to the market. With their dedication to innovation and their track record of success, there is no doubt that {Company} will continue to be a driving force in the development of rigid-flex PCBs and other advanced electronic components.In conclusion, rigid-flex PCBs are a game-changer in the world of electronic design, and {Company} is leading the charge in bringing this exciting technology to the market. With their commitment to excellence and their reputation for innovation, {Company} is set to continue making a significant impact in the world of electronic components and systems. Watch this space for more exciting developments from {Company}, and see how they continue to shape the future of electronics with their cutting-edge solutions.

Understanding the Difference Between SMD and THT Components

Over the years, the demand for innovative and efficient electronic components has been on the rise as the technology industry continues to advance at a rapid pace. In response to this growing need, {} has been making great strides in the development and production of SMD and THT components.With a wide range of products to offer, {} has established itself as a leading provider of electronic components for various industries including telecommunications, automotive, consumer electronics, and more. The company takes pride in its ability to deliver high-quality components that meet the stringent requirements of modern technology and has earned a reputation for reliability and excellence in the industry.SMD (Surface Mount Device) and THT (Through-Hole Technology) components are essential building blocks in the manufacturing of electronic devices. SMD components are small, lightweight, and ideal for high-density circuit board assembly, while THT components are suitable for applications where durability and ease of servicing are paramount. {} produces a comprehensive range of SMD and THT components, including resistors, capacitors, diodes, integrated circuits, and more, to cater to a wide variety of electronic applications.One of the key strengths of {} lies in its ability to adapt to the constantly evolving needs of the market. The company invests heavily in research and development to stay ahead of industry trends and to continuously improve its product offerings. This commitment to innovation has enabled {} to introduce cutting-edge SMD and THT components that meet the demands of the latest technologies, making the company a preferred choice for many leading electronics manufacturers.In addition to its focus on technological advancements, {} places a strong emphasis on quality and reliability. The company adheres to strict quality control measures throughout the manufacturing process to ensure that its components meet the highest standards. By maintaining stringent quality assurance practices, {} has earned the trust and confidence of its customers, solidifying its position as a trusted supplier of SMD and THT components.Furthermore, {} is committed to sustainability and environmental responsibility in its operations. The company strives to minimize its environmental impact by implementing eco-friendly manufacturing practices and embracing renewable energy sources. By doing so, {} not only contributes to a more sustainable future but also provides eco-conscious solutions to its customers.As the demand for electronic devices continues to grow across various industries, the need for reliable and high-performance SMD and THT components becomes increasingly critical. {} is well-positioned to meet this demand with its comprehensive product range and commitment to technological innovation and quality. The company's dedication to staying ahead of the curve and delivering exceptional products has positioned it as a leader in the electronic components market.In conclusion, {} has solidified its position as a leading provider of SMD and THT components, offering a wide range of high-quality, reliable, and innovative electronic components. With a focus on technological advancement, quality, and sustainability, {} continues to drive progress in the field of electronic components and is well-equipped to meet the evolving needs of the industry. As the company looks to the future, it remains steadfast in its commitment to providing cutting-edge solutions for the rapidly changing technology landscape.

The Role of Passive Devices in Electronic Technology

Passive Devices in Electronics: The Backbone of TechnologyIn the world of electronics, passive devices play a crucial role in the functioning of a wide range of electronic products and systems. These components may not be as flashy or high-profile as their active counterparts, but they are the unsung heroes that provide stability and support to electronic circuits. From resistors and capacitors to inductors and transformers, passive devices are the backbone of technology, enabling the seamless operation of various electronic devices.Among the leading companies in the realm of passive devices is {}. With a long history of innovation and expertise in electronic components, {} has established itself as a trusted name in the industry. The company's dedication to quality and performance has made its products a key component in a diverse array of electronic applications, from consumer electronics to industrial equipment.Resistors are one of the most basic yet essential passive devices used in electronics. They are used to limit the flow of electric current in a circuit and are integral to controlling voltage and current levels. Capacitors, on the other hand, store and release electrical energy, helping to stabilize voltage and filter out noise in electronic circuits. Inductors, with their ability to store energy in a magnetic field, are used in applications such as signal processing and power conversion. Meanwhile, transformers are crucial for converting voltage levels in power distribution systems.In the realm of consumer electronics, passive devices are used in products such as smartphones, tablets, and laptops. These devices rely on resistors, capacitors, and inductors to ensure stable power supply, signal processing, and connectivity. Additionally, passive components play a significant role in the automotive industry, where they are used in various applications such as engine control units, infotainment systems, and advanced driver-assistance systems.In the realm of industrial electronics, passive devices are used in a wide range of applications including power distribution, motor control, and factory automation. The reliability and performance of these components are crucial in ensuring the smooth operation of industrial systems, where downtime can be costly and disruptive.The success of {} in the realm of passive devices can be attributed to its commitment to research and development, as well as its focus on providing high-quality, reliable components. The company's extensive portfolio of passive devices caters to a diverse range of industries and applications, making it a go-to choice for electronic designers and manufacturers.With the rapid advancement of technology, the demand for innovative passive devices continues to grow. As the Internet of Things (IoT) and 5G technology become more pervasive, the need for high-performance passive components that can handle increased data traffic and higher frequencies has become increasingly important. In this dynamic landscape, {} is at the forefront of developing cutting-edge passive devices that are tailored to meet the evolving needs of the industry.In conclusion, passive devices are the unsung heroes of the electronics industry, providing stability and support to a wide range of electronic applications. With a strong focus on quality and innovation, {} has solidified its position as a leading provider of passive devices, catering to the diverse needs of industries ranging from consumer electronics to industrial automation. As technology continues to advance, the role of passive devices in enabling the next generation of electronic products and systems will only become more pronounced.