Top 5 Key Factors in Electronic Board Assembly

By:Admin

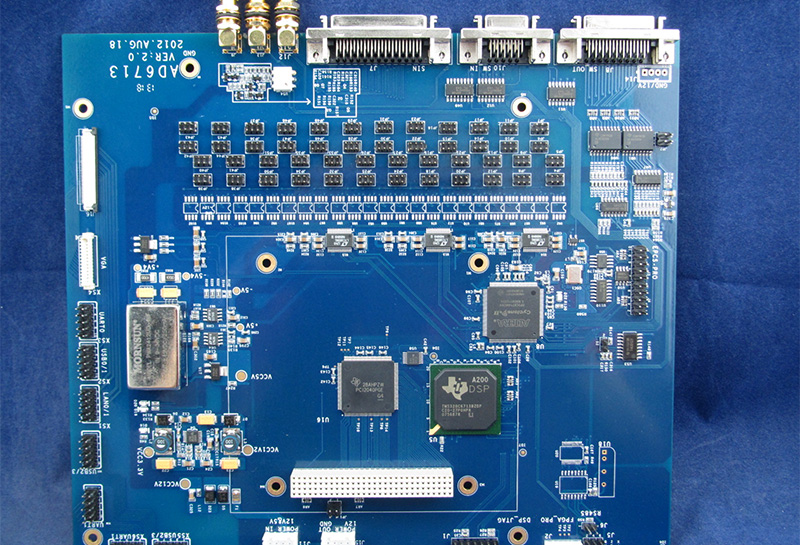

{Company name} is a leading provider of electronic manufacturing services, offering a wide range of solutions, including electronic board assembly, prototyping, product testing, and full turnkey manufacturing. The company has a state-of-the-art facility equipped with advanced machinery and a highly skilled workforce, enabling them to deliver top-notch products to their clients. With a strong focus on research and development, {company name} constantly strives to adapt to the ever-changing technological landscape and deliver cutting-edge solutions to its customers.

In line with its commitment to innovation, {company name} has recently introduced a new electronic board assembly process that is set to revolutionize the industry. The company's new assembly process incorporates the latest technology and industry best practices to ensure superior quality, reliability, and cost-effectiveness. This innovation is a result of {company name}'s continuous investment in research and development, as well as its dedication to staying ahead of the curve in the electronic manufacturing services sector.

The new electronic board assembly process developed by {company name} offers several key benefits to its clients. Firstly, the process is highly efficient, leading to shorter lead times and increased productivity. This is especially crucial in today's fast-paced business environment, where time-to-market is a critical factor in the success of any product. Additionally, the new assembly process ensures the highest level of quality and reliability, meeting the stringent requirements of various industries such as aerospace, automotive, medical devices, and consumer electronics.

Furthermore, {company name}'s new electronic board assembly process is designed to be highly flexible, allowing for customization and scalability to meet the specific needs of its clients. Whether it is a small-scale project or a large-scale production run, the company's advanced assembly process can adapt to the unique requirements of each client, offering a truly tailor-made solution. This level of flexibility is a testament to {company name}'s commitment to customer satisfaction and its ability to offer end-to-end electronic manufacturing services.

As the demand for electronic board assembly continues to rise, {company name} is well-positioned to capitalize on this market growth with its innovative solutions and customer-centric approach. The company's new assembly process is expected to be a game-changer in the industry, setting new standards for quality, efficiency, and reliability. With its proven track record and a strong focus on technological advancement, {company name} is poised to maintain its position as a leader in the electronic manufacturing services sector.

In conclusion, {company name} has once again demonstrated its prowess in the electronic board assembly industry with the introduction of its new assembly process. This innovation is a testament to the company's dedication to staying ahead of the curve and delivering the best-in-class solutions to its clients. As the industry continues to evolve, {company name} remains a reliable partner for electronic manufacturing services, offering cutting-edge solutions that meet the diverse needs of its clients across various sectors.

Company News & Blog

Essential Guide to Understanding the Empty PCB Board

It has recently been reported that a leading manufacturer of electronic components, {Company}, has launched a new line of empty PCB boards. These PCB boards are designed to provide a versatile and customizable solution for electronic manufacturers and hobbyists.{Company} is known for its innovative approach to electronic components, and the introduction of these empty PCB boards is a testament to their commitment to providing quality products to their customers. The company specializes in the production of a wide range of electronic components, including PCB boards, connectors, and cables. With a focus on research and development, {Company} has built a strong reputation for producing high-quality and reliable electronic components.The new line of empty PCB boards from {Company} offers a range of benefits for electronic manufacturers and hobbyists. These boards are designed to be easily customizable, allowing users to create unique designs tailored to their specific needs. The empty PCB boards also provide a cost-effective solution for manufacturers, as they can be easily integrated into existing electronic products.In addition to their customizability and cost-effectiveness, the empty PCB boards from {Company} are also known for their high-quality construction. The company utilizes advanced production techniques and strict quality control measures to ensure that each PCB board meets the highest standards of performance and reliability.Furthermore, the introduction of these empty PCB boards reflects {Company}'s commitment to sustainability. The company has implemented eco-friendly production practices and uses recyclable materials in the manufacturing of their products. By offering an option for reusable and customizable PCB boards, {Company} is providing a sustainable solution for electronic manufacturers and hobbyists.{Company}'s empty PCB boards have already garnered significant interest from the electronic manufacturing industry. Many manufacturers are excited about the prospect of being able to create unique electronic products with the help of these customizable PCB boards. Additionally, hobbyists are also eager to take advantage of the versatility and cost-effectiveness offered by {Company}'s new line of products.As the demand for customizable electronic components continues to grow, {Company} is well-positioned to become a leading provider of empty PCB boards. With their commitment to innovation, quality, and sustainability, the company is poised to set a new standard in the electronic manufacturing industry.Overall, the introduction of empty PCB boards from {Company} represents a significant development in the electronic manufacturing industry. The customizable nature, cost-effectiveness, and high-quality construction of these boards make them an attractive option for manufacturers and hobbyists alike. With a strong reputation for producing reliable electronic components, {Company} is well-equipped to meet the growing demand for customizable and sustainable PCB boards.

High-Quality PCB Assembly Services: Get Your Order Completed Today

Order Pcb Assembly, a leading provider of high-quality printed circuit board (PCB) assembly services, has recently announced the launch of their latest product. With a commitment to delivering innovative solutions and exceptional customer service, Order Pcb Assembly is dedicated to meeting the needs of their clients in various industries.With extensive experience in PCB assembly, Order Pcb Assembly has earned a reputation for delivering reliable and cost-effective solutions. The company's state-of-the-art facilities and advanced technology enable them to produce high-quality PCB assemblies with precision and efficiency. Whether it's a simple prototype or a complex production run, Order Pcb Assembly has the capabilities to meet the unique requirements of their clients.One of the key factors that sets Order Pcb Assembly apart from their competitors is their commitment to quality. The company adheres to strict quality control measures throughout the assembly process to ensure that each product meets the highest standards. By utilizing advanced testing and inspection procedures, Order Pcb Assembly is able to identify and rectify any potential issues before the final product is delivered to the client.In addition to their dedication to quality, Order Pcb Assembly is also known for their exceptional customer service. The company's team of experienced professionals works closely with clients to understand their specific needs and provide tailored solutions. From the initial design phase to final production, Order Pcb Assembly is committed to delivering excellent service every step of the way."We are thrilled to launch our latest product and to continue serving our clients with the exceptional quality and service they have come to expect from us," said [Company Representative]. "At Order Pcb Assembly, we understand the importance of reliable and high-quality PCB assemblies in the success of our clients' projects, and we are dedicated to meeting their needs with precision and efficiency."With the launch of their latest product, Order Pcb Assembly aims to further solidify their position as a leading provider of PCB assembly services. The company's continued investment in technology and their commitment to delivering exceptional quality and service have positioned them as a trusted partner for clients across various industries.As a testament to their success, Order Pcb Assembly has received accolades from clients for their exceptional performance and reliability. The company's ability to deliver high-quality PCB assemblies within tight deadlines has earned them a loyal customer base and a strong reputation in the industry.In conclusion, Order Pcb Assembly's latest product launch further solidifies their position as a leading provider of high-quality PCB assembly services. With a commitment to quality, innovation, and exceptional customer service, the company continues to meet the unique needs of their clients and exceed their expectations. As they continue to invest in technology and expand their capabilities, Order Pcb Assembly is well-positioned to lead the industry in delivering reliable and cost-effective PCB assembly solutions.

New Integrated Inductor Technology Revolutionizes Power Electronics

Integrated inductors are an essential component in many electronic devices, and the demand for smaller, more efficient inductors has been growing in recent years. This demand has been met by the innovative technology developed by a leading electronics company, which has introduced a cutting-edge integrated inductor that is set to revolutionize the industry.The company, a global leader in the design and manufacturing of electronic components, has been at the forefront of technological advancements in the field of integrated inductors. With a rich history of developing innovative solutions for a wide range of applications, the company has established itself as a trusted partner for their customers worldwide.The new integrated inductor developed by the company boasts a compact design and high efficiency, making it ideal for use in a variety of electronic devices. The inductor is designed to provide superior performance while taking up less space, meeting the industry's growing demand for smaller and more efficient components.The integrated inductor is also designed to operate at higher frequencies, making it suitable for use in a wide range of applications, including power management, RF communications, and automotive electronics. Its high efficiency and compact size make it an attractive choice for manufacturers looking to optimize the performance of their products without compromising on space or power requirements.One of the key advantages of the integrated inductor is its ability to reduce electromagnetic interference, which can be a major challenge in electronic devices. By minimizing electromagnetic interference, the inductor helps improve the overall performance and reliability of the devices in which it is used, making it a valuable addition to any electronic design.In addition to its technical capabilities, the integrated inductor also offers cost-saving benefits for manufacturers. By streamlining the design and production process, the inductor helps manufacturers reduce the overall cost of their electronic devices, making it an attractive choice for companies looking to maximize their return on investment.The company's integrated inductor has already generated significant interest among industry professionals, with many praising its innovative design and superior performance. Engineers and designers are eager to integrate the inductor into their next-generation products, confident that it will help them achieve their performance and space-saving goals.In response to the growing demand for the integrated inductor, the company has ramped up production and expanded its distribution channels to make the component readily available to manufacturers worldwide. With its commitment to quality and customer satisfaction, the company is poised to meet the needs of its customers and maintain its position as a leader in the electronic components industry.As the demand for smaller, more efficient electronic components continues to grow, the introduction of the integrated inductor by the company is set to have a significant impact on the industry. With its superior performance, compact design, and cost-saving benefits, the inductor is poised to revolutionize the way electronic devices are designed and manufactured.In conclusion, the introduction of the integrated inductor by the company represents a major advancement in the field of electronic components. With its innovative design, high efficiency, and cost-saving benefits, the inductor is set to become a key enabler for manufacturers looking to optimize the performance and space requirements of their electronic devices. As the industry continues to evolve, the company is well-positioned to lead the way with its cutting-edge technology and unwavering commitment to customer satisfaction.

Create Stunning Street Art with Large Stencil Designs

Company X, a leading provider of innovative stencils and printing solutions, has recently unveiled a new addition to its product lineup - the Big Size Stencil. This new stencil is designed to meet the increasing demand for larger-scale printing in various industries, including advertising, signage, and manufacturing.The Big Size Stencil is part of Company X's commitment to providing high-quality and versatile printing solutions to its customers. With its large size capabilities, the stencil is ideal for creating eye-catching and impactful designs on a variety of surfaces, including walls, floors, and outdoor spaces. Whether used for branding, promotional purposes, or artistic expressions, the Big Size Stencil offers endless possibilities for businesses and individuals looking to make a statement with their printed materials.In addition to its impressive size, the Big Size Stencil is also known for its durability and ease of use. Made from high-quality materials, the stencil is built to withstand the rigors of outdoor use, ensuring that the printed designs remain vibrant and long-lasting. Furthermore, it is easy to clean and maintain, making it a practical and cost-effective choice for businesses and organizations looking to invest in a reliable printing solution."We are thrilled to introduce the Big Size Stencil to the market," said the spokesperson for Company X. "We understand the growing demand for large-scale printing and the need for high-quality, durable stencils that can deliver outstanding results. The Big Size Stencil is a testament to our dedication to innovation and our commitment to providing our customers with the best printing solutions available."The introduction of the Big Size Stencil comes at a time when businesses are increasingly looking for effective ways to stand out and make an impact with their marketing and branding efforts. With its ability to produce large, attention-grabbing designs, the Big Size Stencil is poised to become a valuable tool for businesses looking to create memorable experiences for their customers and target audience.In addition to its use in the commercial sector, the Big Size Stencil also has applications in the artistic and creative fields. Artists and designers can use the stencil to create large-scale murals and artworks, adding a new dimension to their creative expressions. The versatility of the stencil opens up new opportunities for artistic collaborations and community projects, further demonstrating its potential as a valuable and impactful tool for creative endeavors.As Company X continues to expand its product offerings and explore new avenues for innovation, the introduction of the Big Size Stencil represents an exciting development for the company and its customers. With its emphasis on quality, durability, and versatility, the Big Size Stencil is poised to become a game-changer in the world of large-scale printing, offering businesses and individuals a powerful tool for making a lasting impression with their printed materials.In conclusion, the launch of the Big Size Stencil underscores Company X's commitment to providing cutting-edge printing solutions that meet the evolving needs of its customers. With its impressive size, durability, and versatility, the Big Size Stencil is set to redefine the possibilities of large-scale printing, offering businesses, organizations, and creatives a powerful tool for bringing their visions to life. As the demand for impactful and eye-catching printed materials continues to grow, the Big Size Stencil is well-positioned to become an essential tool for those looking to make a lasting impression in the ever-competitive marketplace.

Flexible PCB with Two Layers: What You Need to Know

Two Layers Flexible PCB Market Growing at a Rapid PaceThe global Two Layers Flexible PCB market is anticipated to witness significant growth in the coming years, primarily due to the increasing demand for flexible electronic devices in various industries. A Two Layers Flexible PCB, also known as a Flexible Printed Circuit Board, is a type of circuit board that can be bent, twisted, and folded to fit into compact and irregularly shaped electronic devices. These boards are made from flexible and durable materials, such as polyimide or PEEK, which allows them to withstand high temperatures, vibrations, and mechanical stress.One of the key players in the Two Layers Flexible PCB market is [], a leading manufacturer and supplier of flexible electronic components. The company offers a wide range of Two Layers Flexible PCBs that are designed to meet the specific requirements of various industries, including automotive, aerospace, medical, and consumer electronics. Their Two Layers Flexible PCBs are known for their high flexibility, reliability, and durability, making them ideal for use in a wide range of applications.The increasing adoption of flexible electronic devices in the automotive industry is expected to be a major driving force behind the growth of the Two Layers Flexible PCB market. Car manufacturers are increasingly incorporating flexible electronic components, such as Two Layers Flexible PCBs, into their vehicles to improve safety, convenience, and performance. These flexible components allow for greater design flexibility, reduced weight, and improved space utilization, which is driving their adoption in automotive applications.In addition to the automotive industry, the aerospace sector is also expected to drive the demand for Two Layers Flexible PCBs. The lightweight and durable nature of Two Layers Flexible PCBs make them well-suited for use in aircraft systems, including avionics, communication systems, and entertainment systems. As the aerospace industry continues to focus on improving fuel efficiency and reducing emissions, the demand for lightweight and flexible electronic components is expected to increase, further driving the growth of the Two Layers Flexible PCB market.The medical industry is another key segment expected to contribute to the growth of the Two Layers Flexible PCB market. Flexible electronic devices are becoming increasingly important in medical applications, as they allow for greater flexibility and freedom of movement. Two Layers Flexible PCBs are used in medical devices such as wearable health monitors, implantable devices, and diagnostic equipment, driving the demand for these flexible components in the medical industry.The consumer electronics industry is also expected to play a significant role in the growth of the Two Layers Flexible PCB market. The demand for flexible electronic devices, such as foldable smartphones, wearable devices, and flexible displays, is on the rise, driving the need for Two Layers Flexible PCBs. As consumer electronics manufacturers continue to innovate and develop new products, the demand for flexible electronic components is expected to increase, further fueling the growth of the Two Layers Flexible PCB market.With the increasing demand for flexible electronic devices across various industries, the global Two Layers Flexible PCB market is expected to witness significant growth in the coming years. As a leading manufacturer and supplier of flexible electronic components, [] is well-positioned to capitalize on this growing market opportunity. Their high-quality and reliable Two Layers Flexible PCBs are expected to play a key role in meeting the increasing demand for flexible electronic components in the automotive, aerospace, medical, and consumer electronics industries.

Rigid PCB: Latest News and Developments in the Industry

[Company Name] Introduces State-of-the-Art Fr4 Rigid PCB for Enhanced Electronic Performance[City, State] – [Company Name], a leading manufacturer of high-quality electronic components, is proud to announce the launch of its latest innovation in the field of printed circuit boards (PCBs). The new Fr4 Rigid PCB is specially designed to meet the increasing demand for high-performance and reliable electronic devices in various industries.The Fr4 Rigid PCB is a type of printed circuit board that is known for its durability, stability, and excellent electrical performance. It is made from a type of flame-retardant fiberglass material known as Fr4, which provides the PCB with exceptional strength and resistance to heat. This makes it an ideal choice for electronic applications that require reliable and long-lasting performance.With the increasing complexity and miniaturization of electronic devices, there is a growing need for PCBs that can accommodate more components and deliver higher performance. The Fr4 Rigid PCB from [Company Name] is designed to address these demands by offering a robust and versatile platform for a wide range of electronic applications.“Our new Fr4 Rigid PCB is the result of our continuous commitment to excellence and innovation in electronic component manufacturing,” said [Spokesperson’s Name], the CEO of [Company Name]. “We have leveraged our expertise in PCB manufacturing to develop a product that meets the highest standards of quality, reliability, and performance. We are confident that our Fr4 Rigid PCB will exceed the expectations of our customers and provide them with a competitive edge in their respective industries.”The Fr4 Rigid PCB from [Company Name] is available in a variety of configurations to meet the specific requirements of different electronic applications. It can be customized to support different layer counts, trace widths, and materials to ensure optimal performance and compatibility with various electronic designs. Additionally, the PCB can be manufactured with advanced technologies such as controlled impedance and blind/buried vias to further enhance its functionality and integration capabilities.One of the key advantages of the Fr4 Rigid PCB is its ability to withstand harsh environmental conditions and mechanical stresses. This makes it an ideal choice for applications in industries such as aerospace, automotive, telecommunications, and industrial automation, where reliability and durability are crucial requirements. The PCB is also suitable for high-frequency and high-speed applications, thanks to its excellent electrical properties and signal integrity.In addition to its technical capabilities, the Fr4 Rigid PCB from [Company Name] is manufactured in compliance with industry standards and regulatory requirements. It undergoes rigorous quality control processes to ensure that it meets the highest standards of performance, reliability, and safety. This attention to quality and consistency reflects [Company Name]’s long-standing reputation for delivering superior electronic components to its customers.The introduction of the Fr4 Rigid PCB solidifies [Company Name]’s position as a leading provider of advanced electronic solutions for various industries. The company’s commitment to innovation, quality, and customer satisfaction has earned it a strong presence in the global market, and the launch of the new PCB is expected to further enhance its reputation and competitiveness. With its state-of-the-art manufacturing facilities and dedicated team of professionals, [Company Name] is well-positioned to meet the evolving needs of the electronic industry and drive technological advancements.For more information about the Fr4 Rigid PCB and other electronic components from [Company Name], please visit [company website] or contact their sales team at [contact information].About [Company Name]:[Company Name] is a leading manufacturer of high-quality electronic components, including PCBs, connectors, and assemblies. With a focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for various industries, ranging from aerospace and automotive to telecommunications and industrial automation. With state-of-the-art manufacturing facilities and a commitment to excellence, [Company Name] is dedicated to delivering superior electronic solutions that meet the highest standards of performance and reliability.

Top Benefits of Using LED PCB for Your Electronic Projects

Innovative LED PCB Technology Revolutionizes the Electronics IndustryThe global electronics industry is constantly evolving and seeking new technologies to enhance product performance and design. One of the latest advancements in this field is the development of LED PCB technology, which has the potential to revolutionize the way electronic devices are manufactured and used. This groundbreaking technology is being spearheaded by a leading company in the industry- [Company Name].[Company Name] is a renowned leader in the development and manufacturing of innovative electronic components, and their latest breakthrough in LED PCB technology is set to reshape the industry. With a strong focus on research and development, [Company Name] has successfully created a range of LED PCB products that offer unparalleled performance and versatility.LED (Light Emitting Diode) technology has been widely used in various electronic devices and lighting applications due to its energy efficiency, durability, and design flexibility. However, the integration of LED technology into printed circuit boards (PCBs) has been limited by technical challenges. [Company Name] has overcome these limitations by designing and producing LED PCBs that deliver exceptional performance and reliability.By incorporating LED technology directly into the PCB, [Company Name] has opened up new possibilities for product design and functionality. LED PCBs offer a compact and efficient solution for integrating lighting and display functions into a wide range of electronic devices. From consumer electronics to automotive applications, LED PCB technology has the potential to enhance the performance and aesthetics of various products.The benefits of LED PCB technology go beyond just improved design and functionality. These innovative products also contribute to energy savings and environmental sustainability. LED lighting is known for its low power consumption and long lifespan, and when integrated into PCBs, it can help reduce the overall energy consumption of electronic devices. This aligns with [Company Name]'s commitment to sustainable and eco-friendly solutions.With the introduction of LED PCB technology, [Company Name] has solidified its position as a pioneer in the electronics industry. The company's extensive experience and expertise in electronic component manufacturing have allowed them to push the boundaries of innovation and set new standards for the industry. Their LED PCB products have already gained recognition and praise from customers and partners around the world.In addition to the development of LED PCB technology, [Company Name] has also been actively involved in collaborating with partners to explore new applications and markets for this revolutionary technology. By working closely with manufacturers, designers, and engineers, [Company Name] aims to expand the use of LED PCBs across various industries and create new opportunities for growth and innovation.The future of the electronics industry is bright with the emergence of LED PCB technology, and [Company Name] is at the forefront of this transformation. With a strong track record of delivering high-quality electronic components and a clear vision for the future, [Company Name] is poised to lead the way in driving the adoption of LED PCB technology and shaping the next generation of electronic devices.In conclusion, LED PCB technology represents a significant advancement in the electronics industry, and [Company Name] is driving this innovation forward with its cutting-edge products and strategic collaborations. As the demand for energy-efficient and high-performance electronic devices continues to grow, LED PCB technology is poised to play a crucial role in shaping the future of product design and functionality. With [Company Name]'s leadership and expertise in this field, the industry can expect to see a new wave of innovative electronic devices that are powered by LED PCB technology.

Complete Guide to Flexible Circuit Assembly: Tips and Techniques

Flexible Circuit Assembly, based in California, is a leading provider of flexible and rigid-flex printed circuit board assembly, serving the aerospace, medical, defense, and commercial industries. With over 20 years of experience in the industry, Flexible Circuit Assembly has established itself as a reliable and innovative partner for its customers.The company specializes in the design and assembly of custom flexible and rigid-flex circuits, offering a wide range of capabilities to meet the unique needs of its clients. From prototypes to high-volume production, Flexible Circuit Assembly has the expertise and resources to deliver high-quality, reliable solutions for even the most demanding applications.In addition to its manufacturing capabilities, Flexible Circuit Assembly also provides a range of value-added services, including design for manufacturability (DFM) support, component sourcing, test and inspection, and supply chain management. This comprehensive approach allows the company to offer end-to-end solutions to its customers, streamlining the production process and minimizing time-to-market.One of Flexible Circuit Assembly's key differentiators is its commitment to innovation and continuous improvement. The company invests in the latest manufacturing equipment and technology, and its team of engineers and technicians are constantly exploring new materials and techniques to push the boundaries of what is possible with flexible and rigid-flex circuits. This dedication to innovation has enabled Flexible Circuit Assembly to stay ahead of the curve and provide its customers with cutting-edge solutions that meet their evolving needs.Flexible Circuit Assembly takes pride in its quality management system, which is certified to ISO 9001 and AS9100 standards. This commitment to quality ensures that every product that leaves its facility meets the highest standards of reliability and performance, giving customers peace of mind that their circuits will perform as intended in the most demanding environments.As a responsible corporate citizen, Flexible Circuit Assembly also places a strong emphasis on environmental sustainability and social responsibility. The company complies with all relevant environmental regulations and strives to minimize its environmental footprint through responsible manufacturing practices. Additionally, Flexible Circuit Assembly is committed to creating a safe and inclusive workplace for its employees, and actively supports the local communities in which it operates.Looking to the future, Flexible Circuit Assembly is poised for continued growth and success. The company is constantly expanding its capabilities and capacity to meet the growing demand for flexible and rigid-flex circuits, while also exploring new opportunities in emerging technologies such as wearable electronics and Internet of Things (IoT) devices. With its strong foundation of expertise, innovation, and commitment to quality, Flexible Circuit Assembly is well-positioned to be a trusted partner for its customers for years to come.In conclusion, Flexible Circuit Assembly is a leading provider of flexible and rigid-flex printed circuit board assembly, with the expertise and capabilities to meet the unique needs of customers in a variety of industries. The company's commitment to innovation, quality, and social responsibility makes it a valuable partner for customers seeking reliable and high-performance circuit solutions. As the demand for flexible and rigid-flex circuits continues to grow, Flexible Circuit Assembly is well-positioned to capitalize on new opportunities and drive the industry forward.

How to Make a Multilayer PCB for DIY Projects

Multilayer PCBs are widely used in various electronic devices and systems due to their ability to accommodate more complex circuitry in a smaller space. With the increasing demand for advanced electronics, the need for high-quality multilayer PCBs has become more significant than ever. As a leading manufacturer in the industry, {Company Name} has been at the forefront of producing innovative multilayer PCBs to meet the evolving needs of the market.{Company Name} is recognized for its expertise in designing and manufacturing high-density interconnect (HDI) PCBs, rigid-flex PCBs, and of course, multilayer PCBs. With a strong focus on research and development, the company has consistently pushed the boundaries of technology to deliver cutting-edge solutions for its customers. The commitment to quality and reliability has made {Company Name} a trusted partner for businesses across various sectors including telecommunications, automotive, consumer electronics, and aerospace.In line with its dedication to innovation, {Company Name} has recently introduced a new DIY multilayer PCB solution that empowers customers to create customized multilayer PCBs tailored to their specific requirements. This new offering is set to revolutionize the way businesses approach PCB design and manufacturing, giving them greater control and flexibility in producing high-quality multilayer PCBs.The DIY multilayer PCB solution from {Company Name} leverages advanced technologies and state-of-the-art production processes to enable customers to design and assemble their multilayer PCBs with ease. The solution provides a user-friendly interface and intuitive tools that simplify the design process, allowing customers to bring their ideas to life without the need for extensive technical knowledge or expertise in PCB design.One of the key features of the DIY multilayer PCB solution is its modular approach, which allows customers to select from a range of materials, stackup configurations, and technologies to create a customized multilayer PCB that meets their specific performance and application requirements. This level of customization gives customers the freedom to optimize their multilayer PCBs for factors such as signal integrity, power distribution, thermal management, and EMI/EMC considerations.Additionally, the DIY multilayer PCB solution from {Company Name} streamlines the assembly process by providing customers with access to a comprehensive set of assembly guidelines and best practices. This ensures that customers can effectively translate their designs into fully functional multilayer PCBs with minimal room for error, thereby reducing time-to-market and overall production costs.Furthermore, {Company Name} offers technical support and expertise to assist customers throughout the DIY multilayer PCB assembly process, ensuring that they can leverage the full potential of the solution and achieve optimal results. The company's team of experienced engineers and PCB specialists are on hand to provide guidance, troubleshoot any issues, and offer valuable insights to help customers maximize the performance and reliability of their multilayer PCBs.The introduction of the DIY multilayer PCB solution represents a significant milestone for {Company Name} as it reaffirms the company's commitment to empowering its customers with cutting-edge technologies and innovative solutions. By enabling customers to take control of their multilayer PCB designs and assembly processes, {Company Name} is providing a competitive edge that can drive greater innovation and success for businesses across diverse industries.In conclusion, the DIY multilayer PCB solution from {Company Name} sets a new standard for flexibility, customization, and ease of assembly in the multilayer PCB market. With its advanced capabilities and comprehensive support, the solution is poised to reshape the landscape of multilayer PCB design and manufacturing, offering customers unparalleled opportunities to realize their unique visions and achieve superior performance in their electronic products and systems.

How Circuit Board Assembly Works: Everything You Need to Know

[Company Introduction: eManufacturing Solutions (EMS) is a leading provider of electronic manufacturing services, specializing in PCB assembly, cable assembly, and electronic product assembly. With state-of-the-art facilities and advanced technology, EMS is committed to delivering high-quality, cost-effective solutions to meet the diverse needs of its clients. The company's team of experienced professionals ensures efficient production, timely delivery, and exceptional customer service.]Circuit Board Assembly: Innovating for the FutureIn the fast-paced world of electronics manufacturing, the assembly of circuit boards is a critical process that requires precision, skill, and advanced technology. With the demand for smaller, more powerful electronic devices on the rise, manufacturers are constantly seeking innovative ways to improve their circuit board assembly processes. One company at the forefront of this innovation is eManufacturing Solutions (EMS), a leading provider of electronic manufacturing services.EMS has established itself as a trusted partner for clients seeking high-quality PCB assembly, cable assembly, and electronic product assembly. The company's state-of-the-art facilities and cutting-edge technology enable it to meet the diverse and demanding needs of its clients, delivering exceptional results every time.At the heart of EMS's electronic manufacturing services is its circuit board assembly process. This crucial step in the production of electronic devices requires precision and expertise to ensure optimal performance and reliability. EMS's team of skilled professionals is dedicated to meeting these high standards, using advanced equipment and industry-leading techniques to achieve superior results.One of the key factors that set EMS apart in the field of circuit board assembly is its commitment to innovation. The company continually invests in research and development to stay ahead of the curve, incorporating the latest technological advancements into its assembly processes. This dedication to innovation enables EMS to offer cutting-edge solutions that meet the evolving needs of the electronics industry.In addition to innovation, EMS prioritizes quality in its circuit board assembly services. The company has implemented rigorous quality control measures to ensure the highest level of reliability and performance in every circuit board it assembles. By adhering to industry standards and best practices, EMS consistently delivers products that meet or exceed its clients' expectations.Furthermore, EMS's expertise in circuit board assembly extends to a wide range of electronic devices, from consumer electronics to industrial equipment. The company's versatile capabilities and adaptable processes enable it to support clients across various sectors, delivering tailored solutions to meet their specific requirements.As a leader in electronic manufacturing services, EMS understands the importance of collaboration and partnership. The company works closely with its clients to develop customized circuit board assembly solutions that align with their unique needs and objectives. Whether it's a complex, high-density PCB or a specialized assembly process, EMS has the expertise and resources to deliver the best possible outcome.Looking ahead, EMS is poised to continue its legacy of excellence in circuit board assembly and electronic manufacturing services. With a strong focus on innovation, quality, and customer satisfaction, the company is well-equipped to meet the evolving demands of the electronics industry and to contribute to its continued growth and advancement.In conclusion, circuit board assembly is a critical aspect of electronic manufacturing, and EMS is a leading provider of cutting-edge solutions in this field. With its commitment to innovation, quality, and customer partnership, EMS sets the standard for excellence in PCB assembly and electronic manufacturing services. As the electronics industry continues to evolve, EMS is well-positioned to drive progress and deliver superior results for its clients.