New electric test improves performance and safety standards

By:Admin

Electric Test Working, a leading company in the electrical testing industry, is set to revolutionize the way electrical testing is conducted with its innovative technology. With a focus on efficiency, accuracy, and safety, Electric Test Working is poised to make a significant impact on the electrical testing market.

Founded in 2010, Electric Test Working has quickly established itself as a key player in the electrical testing industry. The company is known for its commitment to quality and innovation, and has built a reputation for delivering reliable and cutting-edge products and services to its clients. Electric Test Working's team of experienced engineers and technicians are dedicated to pushing the boundaries of technology to provide solutions that meet the evolving needs of the electrical testing industry.

One of Electric Test Working's most significant achievements to date is the development of its proprietary testing technology. This innovative technology is designed to streamline the testing process, making it faster, more accurate, and safer than ever before. By leveraging the latest advancements in automation and data analysis, Electric Test Working's testing technology is able to deliver results with unprecedented speed and precision, allowing for more efficient and effective testing procedures.

The impact of Electric Test Working's technology is already being felt across the industry. By enabling technicians to conduct tests with greater speed and accuracy, Electric Test Working is helping to reduce downtime and improve overall productivity for its clients. In addition, the enhanced safety features of the technology are providing peace of mind to technicians, ensuring that they can perform their jobs with confidence and security.

Electric Test Working is also committed to providing comprehensive training and support to its clients to ensure they can fully leverage the benefits of its technology. The company's team of experts offers hands-on training and ongoing support to help clients integrate the technology into their workflows and maximize its impact on their operations.

Looking ahead, Electric Test Working is dedicated to continuing its mission to revolutionize the electrical testing industry. The company is actively investing in research and development to further enhance its technology and explore new opportunities for innovation. Electric Test Working is also expanding its reach to new markets, seeking to introduce its cutting-edge solutions to a broader audience of clients around the world.

The future of electrical testing is rapidly evolving, and Electric Test Working is at the forefront of this transformation. Through its unwavering commitment to innovation and excellence, Electric Test Working is poised to continue shaping the industry and setting new standards for electrical testing technology.

As the industry continues to evolve, Electric Test Working remains firmly focused on delivering solutions that meet the evolving needs of its clients. With its innovative technology, commitment to quality, and dedication to advancement, Electric Test Working is set to remain a driving force in the electrical testing industry for years to come.

Company News & Blog

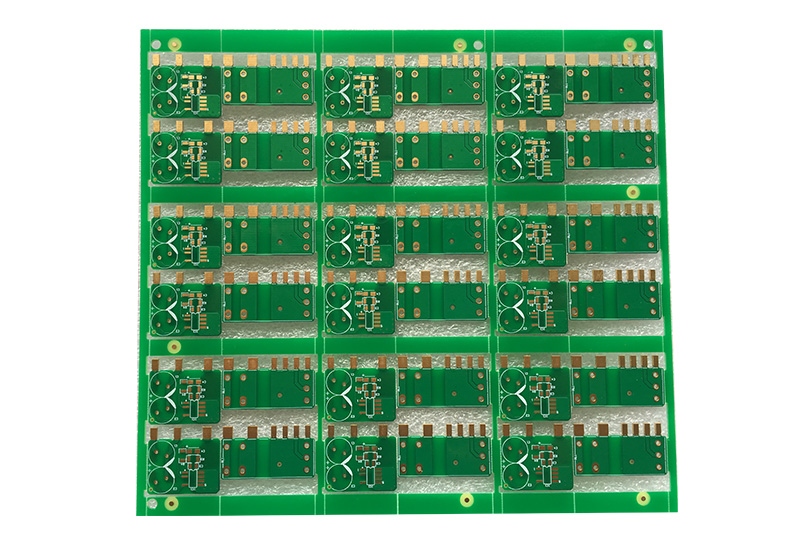

Essential guide to industrial control PCBA: Everything you need to know

Industrial Control PCBA: Revolutionizing Manufacturing ProcessesIn today's rapidly evolving manufacturing environment, the demand for efficient and reliable industrial control systems has never been higher. As factories strive to increase productivity and meet the growing demands of the market, the need for advanced control technologies has become increasingly apparent. One company that has been at the forefront of this technological revolution is {}, a leading provider of innovative industrial control PCBA solutions.Established in {}, {} has quickly established itself as a trusted name in the industry, with a strong track record of delivering high-quality PCBA solutions to a wide range of clients. Specializing in industrial control systems, the company has developed a reputation for innovation and excellence, consistently pushing the boundaries of what is possible in the world of manufacturing technology.At the heart of {}'s offerings is its industrial control PCBA, a cutting-edge solution that is designed to optimize the performance of manufacturing processes. By integrating state-of-the-art components and advanced software, the PCBA is able to provide precise control over a wide range of industrial equipment, helping to improve efficiency, reduce downtime, and minimize production costs.One of the key advantages of {}'s industrial control PCBA is its versatility. Whether it's being used in a large-scale automotive assembly line or a small-scale electronics manufacturing facility, the PCBA can be easily customized to meet the specific needs of the client. This flexibility has made it a popular choice among manufacturers looking to streamline their operations and gain a competitive edge in the market.In addition to its impressive capabilities, {}'s industrial control PCBA is also known for its reliability. Built to withstand the rigors of the industrial environment, the PCBA is engineered to deliver consistent performance even in the most challenging conditions. This level of durability has made it a popular choice among clients who are looking for a long-term solution that can stand the test of time.Another key feature of {}'s industrial control PCBA is its user-friendly interface. With intuitive controls and a simple, easy-to-understand layout, the PCBA is designed to be accessible to operators of all skill levels. This has helped to minimize training time and ensure that clients are able to make the most of their investment from day one.Looking ahead, {} is committed to continuing its tradition of innovation and excellence in the field of industrial control systems. The company's team of dedicated engineers and technicians are constantly working to develop new and improved solutions that will further enhance the efficiency and productivity of manufacturing processes. With a strong focus on research and development, {} is well-positioned to remain a leader in the industry for years to come.Overall, {}'s industrial control PCBA is playing a crucial role in revolutionizing manufacturing processes around the world. By providing clients with a powerful, reliable, and user-friendly solution, the company is helping to drive the industry forward and unlock new levels of productivity and efficiency. As the demand for advanced industrial control systems continues to grow, {} is well-equipped to meet the needs of the market and continue its success as an industry leader.

Assembly Board Discusses New Policies and Initiatives

Board Assembly (Yueqing City, China) recently held its annual board meeting to discuss the company's performance over the past year and to make plans for the future. The meeting was attended by the company's board members, executives, and key stakeholders, and it proved to be a successful and productive event.Board Assembly is a leading manufacturer of electronic components and accessories, serving a global customer base with high-quality products and excellent customer service. The company has been in business for over 20 years, and it has built a strong reputation for innovation, reliability, and value.During the board meeting, the company's Chairman, Mr. Zhang, started the proceedings by providing an overview of the company's performance in the past year. He highlighted the company's achievements, including revenue growth, improved production efficiency, and the successful launch of several new product lines. Mr. Zhang also praised the hard work and dedication of the company's employees, emphasizing their role in the company's success.Following Mr. Zhang's presentation, the board members and executives discussed the company's strengths and weaknesses, as well as the opportunities and threats facing the business. They analyzed market trends, customer feedback, and industry dynamics to identify areas for improvement and potential areas for expansion.One of the key topics of discussion was the company's commitment to sustainability and corporate social responsibility. Board Assembly has always been dedicated to operating in an environmentally friendly and socially responsible manner, and the company's leadership team reaffirmed their commitment to these values. They discussed plans to reduce the company's carbon footprint, minimize waste, and contribute to the communities in which the company operates.The board meeting also provided an opportunity for the company's executives to present their plans for the coming year. They outlined new product development initiatives, marketing strategies, and sales targets, all aimed at driving further growth and success for the company. The presentations were met with enthusiasm and support from the board members, who expressed confidence in the company's ability to achieve its goals.In addition to discussing the company's business strategy, the board meeting also addressed governance matters and corporate compliance. The board members reviewed the company's corporate governance framework, ensuring that it aligns with best practices and regulatory requirements. They also discussed risk management and internal controls, taking steps to ensure that the company operates with the highest standards of integrity and accountability.Overall, the board meeting proved to be a valuable and constructive event, providing a platform for the company's leadership to come together to reflect on the past and plan for the future. The company's commitment to excellence, innovation, and sustainability was evident throughout the meeting, and the board members and executives left feeling motivated and inspired.Looking ahead, Board Assembly is poised to continue its success, building on its strong foundation and leveraging its core strengths to drive further growth and value for its customers, employees, and stakeholders. As the company continues to evolve and adapt to the changing business landscape, it remains committed to its mission of delivering top-quality products and exceptional service, maintaining the trust and confidence of its customers around the world.

Complete Guide to Checking Voltage with a Multimeter

Multimeter Check VoltageA multimeter is a vital tool for any electrician, technician, or engineer. It is an essential device used to measure voltage, current, and resistance in electrical circuits. The accuracy and reliability of a multimeter are crucial in diagnosing and troubleshooting electrical problems. With the evolution of technology, there are now several multimeter brands available in the market, each offering different features and capabilities. However, when it comes to checking voltage, accuracy is of utmost importance. That's why it's important to choose a multimeter that can provide precise voltage readings.One of the leading companies in the multimeter industry is {}. With decades of experience in manufacturing high-quality electrical testing equipment, {} has established itself as a reputable and reliable brand in the market. Their multimeters are known for their accuracy, durability, and user-friendly design, making them a popular choice among professionals and DIY enthusiasts alike.When it comes to checking voltage, the {} multimeter is a top choice for many professionals. Its advanced technology and precise measurement capabilities make it a preferred tool for various electrical applications. Whether it's for residential, commercial, or industrial use, {} multimeters are designed to meet the demands of diverse electrical environments.One of the key features of the {} multimeter is its ability to accurately measure both AC and DC voltage. This is crucial in determining the presence of voltage and identifying any fluctuations or irregularities in an electrical circuit. The multimeter's digital display provides clear and easy-to-read voltage readings, ensuring that users can quickly and accurately assess the voltage levels in their electrical systems.In addition to measuring voltage, the {} multimeter also offers additional features such as resistance and continuity testing, making it a versatile tool for comprehensive electrical testing. Its durable construction and user-friendly interface further enhance its usability, allowing professionals to carry out their work with efficiency and confidence.Furthermore, {}multimeters are designed with safety in mind. They are equipped with various safety features such as overload protection and insulated test leads, ensuring that users can work with peace of mind, knowing that they are protected from potential electrical hazards.Customer satisfaction is a top priority for {}, and they stand behind the quality and reliability of their products. With rigorous quality control measures in place, {} is committed to delivering multimeters that meet the highest industry standards and exceed customer expectations.In conclusion, when it comes to checking voltage, a high-quality multimeter is essential for accurate and reliable measurements. With its proven track record and reputation for excellence, the {} multimeter is a trusted choice for professionals who demand precision and performance in their electrical testing equipment. With its advanced features, durability, and safety capabilities, {}multimeters continue to be a preferred tool for a wide range of electrical applications. Whether it's for routine maintenance, troubleshooting, or complex electrical projects, {}multimeters are designed to deliver consistent and dependable results, making them an indispensable tool for anyone working with electrical systems.

Key Steps for Successful Surface Mount Assembly Process

Today, we are excited to announce that our company, a leading provider of electronic manufacturing services, has integrated an advanced Surface Mount Assembly Process into our production capabilities. This cutting-edge technology will enable us to deliver high-quality and cost-effective electronic assemblies to our customers across a variety of industries.Our Surface Mount Assembly Process is a crucial part of our overall electronic manufacturing services. This process allows us to mount electronic components directly onto the surface of printed circuit boards, as opposed to through-hole mounting, which requires drilling holes in the circuit board for component leads to pass through. This method offers several advantages, including smaller component sizes, higher component density, and improved electrical performance.Incorporating this advanced assembly process into our manufacturing capabilities is a testament to our commitment to staying at the forefront of technological advancements in electronic manufacturing. We understand the importance of continuously improving our processes and investing in state-of-the-art equipment to meet the evolving needs of our customers and the industry as a whole.Our company has a long-standing reputation for delivering high-quality electronic assemblies, and the addition of the Surface Mount Assembly Process further solidifies our position as a reliable and innovative partner for electronic manufacturing needs. With this new capability, we are equipped to handle complex and high-volume production requirements while maintaining the highest standards of quality and efficiency.We are dedicated to providing comprehensive electronic manufacturing services to a wide range of industries, including aerospace, automotive, telecommunications, medical devices, and more. Our expertise in Surface Mount Assembly, combined with our extensive experience in electronic design, prototyping, and testing, positions us as a trusted partner for companies seeking reliable and cost-effective manufacturing solutions.Furthermore, our commitment to quality and reliability is reflected in our adherence to industry standards and certifications. Our manufacturing facilities are equipped with the latest technology and staffed by highly skilled professionals who undergo continuous training to ensure that our processes meet the stringent requirements of the industry.With the integration of the Surface Mount Assembly Process, we are able to offer our customers streamlined production processes, reduced manufacturing costs, and faster time-to-market for their electronic products. This is particularly advantageous for industries with rapidly changing technological landscapes and increasing demand for compact and high-performance electronic devices.In addition to enhancing our manufacturing capabilities, the Surface Mount Assembly Process aligns with our efforts to embrace environmentally friendly practices. By minimizing material waste and energy consumption, we are contributing to sustainable and responsible manufacturing processes, which is an important consideration for many of our customers and the industry as a whole.To celebrate the integration of the Surface Mount Assembly Process, we are offering special promotions for new and existing customers who are looking to take advantage of our enhanced capabilities. We invite companies seeking electronic manufacturing solutions to get in touch with us to learn more about how our Surface Mount Assembly Process can benefit their specific requirements.In conclusion, the integration of the Surface Mount Assembly Process into our electronic manufacturing services represents a significant milestone for our company. This advanced technology, combined with our dedication to quality, reliability, and environmental sustainability, further strengthens our position as a leading provider of electronic manufacturing solutions. We are excited to continue serving the needs of our customers with innovative and cost-effective electronic assembly capabilities.

Ultimate Guide to Rigid Flex Circuit Design

Rigid Flex Circuit Design is becoming increasingly popular in the electronics industry due to its unique combination of the flexibility of a flexible circuit and the durability of a rigid circuit. The integration of these two circuit types offers numerous advantages, including reduced assembly time, increased reliability, and improved overall performance. As a leader in the field of electronic manufacturing, {} is proud to offer cutting-edge Rigid Flex Circuit Design services to meet the evolving needs of our customers.Rigid Flex Circuit Design is a specialized technology that allows for the seamless integration of both rigid and flexible circuit designs within a single electronic assembly. This innovative approach offers greater design flexibility and enhanced reliability, making it an ideal solution for a wide range of applications, including aerospace, medical devices, automotive electronics, and consumer electronics.At {}, we have invested heavily in state-of-the-art manufacturing equipment and cutting-edge technology to ensure that we are at the forefront of Rigid Flex Circuit Design. Our team of skilled engineers and technicians are experts in designing and manufacturing Rigid Flex Circuits that meet the highest quality standards. We work closely with our customers to understand their specific requirements and provide customized solutions that meet their unique needs.One of the main advantages of Rigid Flex Circuit Design is its ability to reduce the overall size and weight of electronic assemblies. By combining the functionality of multiple rigid and flexible circuits into a single unit, Rigid Flex Circuits can eliminate the need for additional connectors and wiring, resulting in a more compact and lightweight design. This is particularly beneficial for applications where space is limited or weight restrictions are a concern.In addition to space and weight savings, Rigid Flex Circuit Design also offers enhanced durability and reliability. By minimizing the number of interconnects and solder joints, Rigid Flex Circuits can reduce the risk of mechanical failure and improve overall performance. This makes Rigid Flex Circuits an ideal choice for mission-critical applications where reliability is of utmost importance.Furthermore, the flexibility of Rigid Flex Circuit Design allows for more creative and versatile product designs. With the ability to incorporate three-dimensional configurations and conform to non-planar surfaces, Rigid Flex Circuits enable the development of innovative and ergonomic electronic products that would be impossible to achieve with traditional rigid or flexible circuits alone.As a leading provider of Rigid Flex Circuit Design services, {} is committed to delivering the highest quality products to our customers. Our ISO-certified manufacturing facilities and rigorous quality control processes ensure that every Rigid Flex Circuit we produce meets the strictest quality standards. We also offer comprehensive design support and engineering expertise to help our customers optimize their Rigid Flex Circuit designs for maximum performance and reliability.In conclusion, Rigid Flex Circuit Design offers a wealth of benefits and is rapidly gaining traction in the electronics industry. With our advanced manufacturing capabilities and technical expertise, {} is well-equipped to meet the growing demand for Rigid Flex Circuits and help our customers stay ahead of the competition.Whether you are developing a cutting-edge aerospace application, a life-saving medical device, or a next-generation consumer electronic product, you can count on {} to provide the highest quality Rigid Flex Circuit Design solutions to bring your vision to life. Contact us today to learn more about our Rigid Flex Circuit Design services and how we can help you achieve your electronic manufacturing goals.

A Guide to SMD Components in PCB Manufacturing

Pcb Smd Components, The Future of Electronics ManufacturingIn today's rapidly advancing world, the demand for smaller and more efficient electronic devices is higher than ever. From smartphones to wearable technology, consumers are constantly seeking out products that offer greater functionality in smaller, more compact form factors. This trend has put pressure on electronics manufacturers to develop and produce increasingly miniature components, and one company that is at the forefront of this push is {}.Founded in {} as a small start-up, {} has grown to become a leading provider of innovative electronic components for a wide range of industries. The company has built a reputation for excellence in the field of Printed Circuit Board (PCB) Surface Mount Device (SMD) components, and their products are used by some of the most well-known brands in the world.{}'s success can be attributed to their unwavering commitment to research and development. The company invests heavily in the latest technologies and manufacturing processes, allowing them to stay ahead of the curve in the ever-evolving world of electronics. As a result, {} is able to offer a diverse portfolio of high-quality SMD components that meet the demanding requirements of modern electronic applications.One of the key factors that sets {} apart from their competitors is their ability to produce incredibly small and precise components. With the increasing demand for compact, lightweight electronics, the need for tiny SMD components has never been greater. {} has risen to the challenge by developing cutting-edge manufacturing techniques that enable them to create components with unprecedented levels of miniaturization.The company's commitment to innovation is evident in their latest product offerings, which include an array of advanced SMD components that are smaller, lighter, and more powerful than ever before. These components are designed to enable the next generation of electronic devices, from advanced medical equipment to groundbreaking IoT (Internet of Things) applications.{}'s dedication to quality is also a hallmark of their success. The company adheres to the strictest standards of quality control and testing, ensuring that every component that leaves their facilities meets the highest level of reliability and performance. This commitment to excellence has earned {} a stellar reputation within the industry and has cemented their position as a trusted partner for electronics manufacturers around the world.Looking to the future, {} shows no signs of slowing down. The company continues to invest in research and development, pushing the boundaries of what is possible in the realm of SMD component manufacturing. By staying at the forefront of technological advancements, {} is poised to remain a key player in the ever-expanding electronics market for years to come.In conclusion, {}'s dedication to innovation, quality, and cutting-edge manufacturing processes has made them a leader in the field of SMD components. As the demand for smaller, more efficient electronic devices continues to grow, {} is well-positioned to drive the next wave of technological advancement in the industry. With their unwavering commitment to excellence, {} is truly shaping the future of electronics manufacturing.

Effective PCB Design Methods for Power Electronics

Power Electronics PCB Design: Elevating Performance and EfficiencyIn our fast-paced and dynamic world, the demand for efficient and high-performing power electronics has become increasingly essential. From renewable energy systems to electric vehicles, these electronics play a crucial role in powering the technologies that drive our modern society. Behind the scenes, printed circuit board (PCB) design is at the heart of ensuring the optimal performance and reliability of power electronics.One company that has been leading the way in this domain is {}. With a strong focus on innovative PCB design solutions, {} has consistently delivered cutting-edge technology that has set new benchmarks in the industry. Their expertise in power electronics PCB design has enabled them to develop solutions that are not only powerful and efficient but also reliable and sustainable.One of the key aspects of {}'s PCB design services is their commitment to customized solutions. They understand that every application has unique requirements, and their team of experienced engineers works closely with clients to develop tailored designs that address specific needs. Whether it's designing PCBs for high-power applications or for environments with stringent operating conditions, {} has the expertise to deliver robust and efficient solutions.The company's emphasis on research and development has been instrumental in driving innovation in power electronics PCB design. They continuously invest in state-of-the-art technology and equipment to stay at the forefront of the industry. This commitment to innovation has led to the development of PCB designs that offer improved performance, higher efficiency, and greater reliability.In addition to their technical expertise, {} also places a strong emphasis on sustainability in their PCB design processes. They are dedicated to developing eco-friendly solutions that minimize the environmental impact without compromising on performance. By leveraging their extensive knowledge in materials and manufacturing processes, {} is able to offer PCB designs that are not only energy-efficient but also contribute to the overall sustainability of the power electronics industry.One of the notable achievements of {} in the power electronics PCB design space is their contribution to the advancement of renewable energy systems. Their innovative designs have been instrumental in enhancing the performance and efficiency of solar inverters, wind turbine controllers, and energy storage systems. By optimizing the power electronics at the heart of these renewable energy technologies, {} has played a significant role in driving the transition towards a more sustainable energy landscape.Moreover, {}'s PCB design solutions have also found applications in the rapidly growing electric vehicle (EV) industry. As the demand for electric vehicles continues to rise, the need for high-performance and reliable power electronics becomes increasingly critical. {} has been at the forefront of developing PCB designs for EV powertrains, battery management systems, and on-board chargers, contributing to the acceleration of the electric mobility revolution.With a proven track record of delivering exceptional PCB design solutions, {} has earned the trust of major players in the power electronics industry. Their commitment to quality, innovation, and sustainability has positioned them as a leading provider of power electronics PCB design services.As the demand for efficient and high-performing power electronics continues to soar, the role of PCB design in shaping the future of this industry becomes increasingly significant. With {}'s dedication to pushing the boundaries of innovation, it is poised to play a pivotal role in driving the next wave of advancements in power electronics technology.

New Tech Device Emerges as Must-Have Electronic Gadget for 2022

Active Electronics, a leading provider of electronic solutions and services, has recently announced the launch of their latest line of innovative products. The company, with a rich history of over 20 years in the industry, has continuously strived to bring cutting-edge technology to the market and has gained a strong reputation for their high-quality and reliable products.Active Electronics has been a trailblazer in the electronic industry, consistently pushing the boundaries and setting new standards. The company's commitment to research and development has led to the creation of a diverse range of products that cater to various needs and requirements. From consumer electronics to industrial applications, Active Electronics has been at the forefront of innovation, always staying ahead of the curve."As a company, we have always been driven by our passion for technology and our desire to create products that make a difference in people's lives," says the CEO of Active Electronics. "With our latest line of products, we aim to further solidify our position as a leading provider of electronic solutions and continue to meet the evolving needs of our customers."The new line of products launched by Active Electronics encompasses a wide array of offerings, including smart home devices, audio equipment, and industrial automation solutions. Each product has been meticulously designed and engineered to deliver exceptional performance, reliability, and user experience. With a focus on incorporating the latest advancements in technology, these products are set to redefine the industry standards and provide users with unparalleled value.One of the flagship products in the new lineup is a state-of-the-art smart home hub that seamlessly integrates various home automation devices and enables users to control and monitor their homes with ease. Equipped with advanced connectivity options and intuitive user interface, the smart home hub provides a comprehensive solution for modern home automation needs.In addition to consumer-focused products, Active Electronics has also introduced a range of industrial automation solutions that are designed to streamline processes and improve efficiency in manufacturing and other industrial settings. These solutions leverage cutting-edge technologies such as machine learning and IoT (Internet of Things) to enable predictive maintenance, real-time monitoring, and enhanced productivity.Furthermore, the company has expanded its portfolio of audio equipment with the introduction of high-fidelity speakers and headphones that deliver immersive sound experiences. These audio products have been designed to cater to the discerning needs of audiophiles and music enthusiasts, offering superior performance and uncompromising quality.Active Electronics has also emphasized their commitment to sustainability and environmental responsibility in the development of their new products. Through the use of eco-friendly materials, energy-efficient designs, and responsible manufacturing processes, the company aims to minimize their ecological footprint and contribute to a more sustainable future.The launch of the new product lineup has generated significant excitement and anticipation among consumers and industry professionals alike. With their proven track record of delivering exceptional products, Active Electronics continues to set the bar high for innovation and excellence in the electronic industry.In conclusion, Active Electronics' latest line of products represents a testament to their ongoing dedication to technological advancement and customer satisfaction. With a focus on innovation, quality, and sustainability, the company remains a leading force in the electronic industry and is poised to shape the future of technology with their groundbreaking products.

How to Perform an Electrical Wire Test: A Step-by-Step Guide

Electrical Wire Test Unveils Innovative Solution for Ensuring Safety and QualityIn today's fast-paced world, it's more important than ever for companies to prioritize safety and quality in their products. With the increasing demand for reliable electrical wiring solutions, businesses are constantly seeking new ways to ensure that their products meet the highest safety and quality standards. This is where Electrical Wire Test comes in, offering an innovative solution that is set to revolutionize the industry.Electrical Wire Test, a leading provider of electrical testing services, has recently introduced a breakthrough technology that promises to transform how companies evaluate the safety and quality of their electrical wires. With their cutting-edge testing equipment and in-depth expertise, Electrical Wire Test is helping businesses across various industries to enhance the reliability and performance of their products.One of the key features of Electrical Wire Test's revolutionary solution is its ability to identify potential flaws and weaknesses in electrical wires that could compromise safety and quality. By utilizing state-of-the-art testing methodologies and rigorous inspection processes, the company is empowering businesses to proactively address any issues with their electrical wiring, ensuring that their products are safe and reliable for consumers.Furthermore, Electrical Wire Test's technology offers unmatched precision and accuracy, giving companies the confidence that their electrical wires meet the strictest safety and quality standards. This is particularly crucial in industries where the integrity of electrical wiring is paramount, such as in construction, automotive, and aerospace.In addition to their advanced testing capabilities, Electrical Wire Test prides itself on its team of highly skilled and knowledgeable professionals who are dedicated to delivering exceptional service to their clients. With years of experience and a deep understanding of industry regulations and best practices, the company's experts are well-equipped to assist businesses in navigating the complexities of electrical wire testing."We are committed to providing our clients with the most comprehensive and reliable electrical wire testing services available in the market," said a spokesperson for Electrical Wire Test. "Our goal is to help businesses prioritize safety and quality in their products, and our innovative solution is designed to do just that."The introduction of Electrical Wire Test's groundbreaking technology comes at a time when the demand for safe and high-quality electrical wiring solutions is at an all-time high. As companies strive to meet the evolving needs of consumers and comply with stringent industry standards, the importance of reliable testing services cannot be overstated. Electrical Wire Test stands at the forefront of this movement, offering a game-changing solution that is poised to elevate the safety and quality of electrical wiring across industries.With its unwavering commitment to excellence and innovation, Electrical Wire Test is well-positioned to shape the future of electrical wire testing and set a new benchmark for safety and quality in the industry. As businesses continue to recognize the indispensable value of robust electrical testing, Electrical Wire Test's pioneering solution is sure to become an indispensable asset in their pursuit of delivering superior products to the market.

What is Dielectric Voltage and How Does it Affect Electrical Devices?

The usage of dielectric voltage is an essential component in many industries, playing a crucial role in ensuring the safety and efficiency of various electrical applications. One company that has been at the forefront of dielectric voltage technology is {}. With over 20 years of experience in the industry, {} has established itself as a leading provider of high-quality dielectric voltage products that are used in a wide range of applications, from power generation and distribution to telecommunications and automotive.Dielectric voltage, also known as insulation voltage, refers to the maximum voltage that an insulating material can withstand without breaking down. It is a critical parameter in the design and operation of electrical equipment, as it determines the safety and reliability of the system. In industries where electrical equipment is exposed to high voltages, such as power plants and electric utilities, the importance of reliable dielectric voltage solutions cannot be overstated.{} has been at the forefront of developing innovative dielectric voltage products that meet the stringent requirements of modern industrial applications. The company's expertise in material science and engineering allows it to produce dielectric voltage products that offer exceptional performance and reliability, even in demanding operating conditions. Whether it's high voltage cables for power transmission or insulation materials for electric motors, {} has the right solutions to meet the specific needs of its customers.One of the key strengths of {} is its commitment to research and development. The company invests heavily in R&D to continuously improve its dielectric voltage products and develop new technologies that push the boundaries of what is possible. This dedication to innovation has allowed {} to stay ahead of the competition and offer cutting-edge solutions that address the evolving needs of the industry. By collaborating with leading research institutions and industry partners, {} ensures that its products are at the forefront of technological advancements.Furthermore, {} places a strong emphasis on quality and reliability. All of its dielectric voltage products undergo rigorous testing and quality control procedures to ensure that they meet the highest standards. This commitment to excellence has earned {} a reputation for delivering products that are not only high-performing but also durable and long-lasting. Customers can rely on {} to provide them with solutions that they can trust to perform consistently in their applications.In addition to its technical expertise, {} is also known for its exceptional customer service. The company works closely with its customers to understand their specific requirements and provide them with tailored solutions that meet their needs. Whether it's providing technical support, customizing products, or offering on-site assistance, {} goes the extra mile to ensure that its customers are satisfied with their experience.Looking ahead, {} is poised for further growth and success in the dielectric voltage market. With a strong foundation of technical expertise, a commitment to innovation, and a customer-centric approach, the company is well-positioned to continue leading the way in providing high-quality dielectric voltage solutions for a wide range of industries. As the demand for reliable and efficient electrical equipment continues to grow, {} is ready to meet the challenges and opportunities that lie ahead.