Efficient Ways to Debug Selenium Tests for Better Performance

By:Admin

Debugging Selenium tests is an essential process in the software development lifecycle. It involves identifying and fixing errors, defects, or inconsistencies within the test scripts to ensure that the tests are reliable and produce accurate results. This process is crucial for delivering high-quality web applications and minimizing the risk of potential issues and malfunctions.

To address the importance of debugging Selenium tests, companies such as {} have been focusing on refining their testing processes to ensure the highest level of accuracy and reliability in their web applications. As a leading provider of software solutions, {} has established itself as a pioneer in adopting cutting-edge technologies and best practices to deliver exceptional quality products to their customers.

One of the key challenges in debugging Selenium tests is identifying the root cause of failures. Tests can fail for various reasons, including changes in the application code, environmental factors, or issues with the test scripts themselves. To mitigate these challenges, {} has implemented a robust debugging process that involves thorough analysis of test failures and proactive problem-solving strategies.

In addition to identifying the cause of failures, debugging Selenium tests also involves implementing effective solutions to resolve the issues. This may include updating the test scripts, modifying the test environment, or collaborating with developers to address underlying issues in the application code. By actively addressing and resolving test failures, {} is able to maintain the integrity and accuracy of their automated testing processes.

Furthermore, {} has recognized the importance of leveraging the latest tools and technologies to enhance their debugging capabilities. By utilizing advanced debugging features within Selenium, such as breakpoints, watchpoints, and logging, they are able to efficiently identify and address issues within their test scripts. This proactive approach to debugging enables {} to maintain a high standard of quality and reliability in their web applications.

Moreover, {} has also placed a strong emphasis on continuous integration and continuous testing to streamline their debugging process. By integrating Selenium tests into their CI/CD pipelines, they are able to automate the execution of tests and rapidly identify and address failures as part of their development workflow. This approach not only accelerates the debugging process but also facilitates early detection and resolution of issues, ultimately improving the overall quality of their web applications.

As a result of their dedicated efforts in debugging Selenium tests, {} has significantly enhanced the effectiveness and efficiency of their automated testing processes. By maintaining a strong focus on identifying, addressing, and preventing test failures, they have been able to deliver web applications that are robust, reliable, and of the highest quality. This commitment to excellence has solidified {}'s position as a trusted provider of software solutions, and their approach to debugging Selenium tests serves as a testament to their unwavering dedication to delivering exceptional products to their customers.

In conclusion, debugging Selenium tests is a critical aspect of ensuring the reliability and accuracy of automated testing processes. By actively addressing test failures and implementing effective solutions, companies such as {} are able to uphold the highest standards of quality in their web applications. Through the use of advanced debugging techniques, continuous integration, and a proactive approach to problem-solving, {} has demonstrated a relentless commitment to delivering exceptional software solutions to their customers. As the demand for reliable and high-performing web applications continues to grow, the importance of debugging Selenium tests will remain paramount in the pursuit of excellence in software testing and quality assurance.

Company News & Blog

Top 5 Tips for Outdoor Displaying PCBs: Expert Advice for Effective Results

Outdoor Displaying PCB Revolutionizes Advertising IndustryOutdoor displaying PCB (Printed Circuit Board) technology has revolutionized the advertising industry, providing a more efficient and effective way to reach consumers. This innovative technology, combined with the advanced capabilities of [Company Name], has the power to greatly impact the way businesses advertise and promote their products and services.[Company Name] is a global leader in developing and manufacturing cutting-edge PCB solutions. With over 20 years of experience in the industry, they have continuously pushed the boundaries of innovation to deliver high-quality, reliable, and cost-effective PCB products to their clients. Their commitment to research and development has led to the creation of outdoor displaying PCB, a breakthrough technology that has the potential to transform the advertising landscape.The outdoor displaying PCB is a game-changer for advertisers, as it offers a dynamic and interactive platform to engage with the target audience. By integrating LED lights and advanced circuitry, this technology allows businesses to create eye-catching and attention-grabbing displays that can be placed in outdoor locations, such as shopping malls, public squares, and sports arenas. The versatility of outdoor displaying PCB enables advertisers to deliver their message in a creative and impactful way, effectively capturing the attention of consumers and driving brand awareness.One of the key features of outdoor displaying PCB is its ability to adapt to different lighting conditions. Whether it's daytime or nighttime, this technology ensures that the content is always visible and vibrant. With the use of high-quality components and advanced engineering, [Company Name] has developed outdoor displaying PCB that is resistant to environmental factors such as moisture, heat, and dust, making it suitable for outdoor use in various climates.Furthermore, outdoor displaying PCB offers the flexibility to showcase a wide range of content, including images, videos, and animations. This versatility allows advertisers to tailor their message to specific demographics and target markets, creating a more personalized and impactful advertising experience. With the ability to change content remotely, businesses can update their advertising campaigns in real-time, ensuring that their message remains relevant and engaging.In addition to its visual appeal, outdoor displaying PCB also provides a cost-effective solution for advertisers. The low power consumption and long lifespan of LED lights make this technology an economical choice for businesses looking to maximize their advertising budget. Furthermore, the durability and reliability of outdoor displaying PCB ensure that advertisers can achieve a high return on investment, as these displays require minimal maintenance and upkeep.The introduction of outdoor displaying PCB by [Company Name] marks a significant milestone in the evolution of the advertising industry. By harnessing the power of advanced PCB technology, businesses now have the opportunity to create immersive and impactful advertising experiences that resonate with consumers. As the demand for innovative and interactive advertising solutions continues to grow, outdoor displaying PCB is poised to become a driving force in shaping the future of outdoor advertising.With a proven track record of delivering cutting-edge PCB solutions, [Company Name] is well-positioned to lead the charge in advancing outdoor displaying PCB technology. Their dedication to innovation and excellence sets them apart as a trusted partner for businesses looking to elevate their advertising efforts. As the industry continues to embrace outdoor displaying PCB, [Company Name] remains committed to pushing the boundaries of what's possible, driving the evolution of advertising in the digital age.

Top 5 Key Factors in Electronic Board Assembly

The electronic board assembly industry is witnessing a significant evolution with the latest advancements in technology and increasing demand for high-quality products in various sectors. One company that has been at the forefront of this transformation is {company name}. With its expertise in electronic manufacturing services, {company name} has carved a niche for itself and is recognized as a reliable and innovative partner for electronic board assembly solutions.{Company name} is a leading provider of electronic manufacturing services, offering a wide range of solutions, including electronic board assembly, prototyping, product testing, and full turnkey manufacturing. The company has a state-of-the-art facility equipped with advanced machinery and a highly skilled workforce, enabling them to deliver top-notch products to their clients. With a strong focus on research and development, {company name} constantly strives to adapt to the ever-changing technological landscape and deliver cutting-edge solutions to its customers.In line with its commitment to innovation, {company name} has recently introduced a new electronic board assembly process that is set to revolutionize the industry. The company's new assembly process incorporates the latest technology and industry best practices to ensure superior quality, reliability, and cost-effectiveness. This innovation is a result of {company name}'s continuous investment in research and development, as well as its dedication to staying ahead of the curve in the electronic manufacturing services sector.The new electronic board assembly process developed by {company name} offers several key benefits to its clients. Firstly, the process is highly efficient, leading to shorter lead times and increased productivity. This is especially crucial in today's fast-paced business environment, where time-to-market is a critical factor in the success of any product. Additionally, the new assembly process ensures the highest level of quality and reliability, meeting the stringent requirements of various industries such as aerospace, automotive, medical devices, and consumer electronics.Furthermore, {company name}'s new electronic board assembly process is designed to be highly flexible, allowing for customization and scalability to meet the specific needs of its clients. Whether it is a small-scale project or a large-scale production run, the company's advanced assembly process can adapt to the unique requirements of each client, offering a truly tailor-made solution. This level of flexibility is a testament to {company name}'s commitment to customer satisfaction and its ability to offer end-to-end electronic manufacturing services.As the demand for electronic board assembly continues to rise, {company name} is well-positioned to capitalize on this market growth with its innovative solutions and customer-centric approach. The company's new assembly process is expected to be a game-changer in the industry, setting new standards for quality, efficiency, and reliability. With its proven track record and a strong focus on technological advancement, {company name} is poised to maintain its position as a leader in the electronic manufacturing services sector.In conclusion, {company name} has once again demonstrated its prowess in the electronic board assembly industry with the introduction of its new assembly process. This innovation is a testament to the company's dedication to staying ahead of the curve and delivering the best-in-class solutions to its clients. As the industry continues to evolve, {company name} remains a reliable partner for electronic manufacturing services, offering cutting-edge solutions that meet the diverse needs of its clients across various sectors.

How to Make a Multilayer PCB for DIY Projects

Multilayer PCBs are widely used in various electronic devices and systems due to their ability to accommodate more complex circuitry in a smaller space. With the increasing demand for advanced electronics, the need for high-quality multilayer PCBs has become more significant than ever. As a leading manufacturer in the industry, {Company Name} has been at the forefront of producing innovative multilayer PCBs to meet the evolving needs of the market.{Company Name} is recognized for its expertise in designing and manufacturing high-density interconnect (HDI) PCBs, rigid-flex PCBs, and of course, multilayer PCBs. With a strong focus on research and development, the company has consistently pushed the boundaries of technology to deliver cutting-edge solutions for its customers. The commitment to quality and reliability has made {Company Name} a trusted partner for businesses across various sectors including telecommunications, automotive, consumer electronics, and aerospace.In line with its dedication to innovation, {Company Name} has recently introduced a new DIY multilayer PCB solution that empowers customers to create customized multilayer PCBs tailored to their specific requirements. This new offering is set to revolutionize the way businesses approach PCB design and manufacturing, giving them greater control and flexibility in producing high-quality multilayer PCBs.The DIY multilayer PCB solution from {Company Name} leverages advanced technologies and state-of-the-art production processes to enable customers to design and assemble their multilayer PCBs with ease. The solution provides a user-friendly interface and intuitive tools that simplify the design process, allowing customers to bring their ideas to life without the need for extensive technical knowledge or expertise in PCB design.One of the key features of the DIY multilayer PCB solution is its modular approach, which allows customers to select from a range of materials, stackup configurations, and technologies to create a customized multilayer PCB that meets their specific performance and application requirements. This level of customization gives customers the freedom to optimize their multilayer PCBs for factors such as signal integrity, power distribution, thermal management, and EMI/EMC considerations.Additionally, the DIY multilayer PCB solution from {Company Name} streamlines the assembly process by providing customers with access to a comprehensive set of assembly guidelines and best practices. This ensures that customers can effectively translate their designs into fully functional multilayer PCBs with minimal room for error, thereby reducing time-to-market and overall production costs.Furthermore, {Company Name} offers technical support and expertise to assist customers throughout the DIY multilayer PCB assembly process, ensuring that they can leverage the full potential of the solution and achieve optimal results. The company's team of experienced engineers and PCB specialists are on hand to provide guidance, troubleshoot any issues, and offer valuable insights to help customers maximize the performance and reliability of their multilayer PCBs.The introduction of the DIY multilayer PCB solution represents a significant milestone for {Company Name} as it reaffirms the company's commitment to empowering its customers with cutting-edge technologies and innovative solutions. By enabling customers to take control of their multilayer PCB designs and assembly processes, {Company Name} is providing a competitive edge that can drive greater innovation and success for businesses across diverse industries.In conclusion, the DIY multilayer PCB solution from {Company Name} sets a new standard for flexibility, customization, and ease of assembly in the multilayer PCB market. With its advanced capabilities and comprehensive support, the solution is poised to reshape the landscape of multilayer PCB design and manufacturing, offering customers unparalleled opportunities to realize their unique visions and achieve superior performance in their electronic products and systems.

High Quality Voltage Test Probe for Accurate Electrical Testing

Voltage Test Probe is a vital tool for electricians, technicians, and hobbyists who need to measure and test electrical circuits. These probes are used to verify the presence or absence of voltage in a conductor without the need to make physical contact with the wire, making them essential for ensuring safety while working with electrical systems. For those looking for reliable and accurate voltage test probes, [Company Name] offers a wide range of high-quality and durable probes that meet the needs of professionals and hobbyists alike. The company has been a leading provider of electronic testing equipment for [number] years, and their commitment to quality and customer satisfaction has solidified their reputation as a trusted supplier in the industry.[Company Name] understands the importance of precision and safety when it comes to testing and measuring electrical systems. That's why they offer a variety of voltage test probes that are designed to meet the highest standards of performance and reliability. With features such as insulated shafts, rugged construction, and ergonomic grips, their probes are built to withstand the rigors of daily use in the field.In addition to their standard voltage test probes, [Company Name] also offers specialized probes for specific applications, such as high-voltage testing, automotive diagnostics, and industrial maintenance. These probes are designed to deliver accurate and consistent results in even the most demanding environments, making them an indispensable tool for professionals in a variety of industries.One of the key features of [Company Name]'s voltage test probes is their compatibility with a wide range of multimeters and other testing equipment. This versatility ensures that users can easily integrate the probes into their existing toolkits, allowing for seamless and efficient testing and measurement processes.Furthermore, [Company Name] is committed to providing exceptional customer service and support. Their team of knowledgeable and experienced professionals is dedicated to helping customers find the right solutions for their specific needs, and they are always available to answer questions and provide assistance.Whether you're a seasoned professional or a hobbyist, [Company Name] has the voltage test probes you need to get the job done safely and accurately. With their extensive selection, expert guidance, and unwavering commitment to quality, you can trust [Company Name] to be your go-to source for all of your testing and measurement needs.In conclusion, Voltage Test Probe is an essential tool for anyone working with electrical systems, and [Company Name] offers a wide range of high-quality probes that are designed to meet the needs of professionals and hobbyists. With their commitment to quality, reliability, and customer satisfaction, [Company Name] is the trusted source for all of your testing and measurement needs.

High-Quality Ferrite Inductor for Electronic Devices: A Comprehensive Guide

Ferrite Inductor: The Latest Innovation in Power Electronics TechnologyIn today's rapidly evolving world of technology, the demand for more efficient and reliable electronic components is at an all-time high. This is especially true in the power electronics industry, where the need for smaller, lighter, and more energy-efficient components is driving a wave of innovation and advancement. One such innovation that is making waves in the industry is the Ferrite Inductor, a cutting-edge component that is set to redefine the way power electronics are designed and manufactured.Ferrite Inductors are a type of inductor that are made from ferrite materials, which are known for their high magnetic permeability and low electrical conductivity. This unique combination of properties makes Ferrite Inductors ideal for a wide range of power electronics applications, including power supplies, dc-dc converters, and voltage regulators. One of the key advantages of Ferrite Inductors is their ability to handle high currents and high frequencies, making them an ideal choice for modern power electronics designs that require fast switching speeds and high efficiency.One company that is at the forefront of this exciting new technology is {Company}, a leading manufacturer of electronic components and power supplies. With over {Number} years of experience in the industry, {Company} has built a reputation for delivering high-quality, innovative solutions to meet the evolving needs of the power electronics market. The company's extensive portfolio of products includes a wide range of inductors, transformers, and power supplies, all of which are designed to meet the highest standards of performance and reliability.{Company} has recently unveiled its latest line of Ferrite Inductors, which have been developed using the most advanced materials and manufacturing techniques available. These new Ferrite Inductors offer a number of key advantages over traditional inductor designs, including higher efficiency, lower power losses, and a smaller footprint. This makes them an ideal choice for power electronics designers who are looking to reduce the size and weight of their designs without compromising on performance.In addition to their technical advantages, {Company}'s Ferrite Inductors are also designed to meet the highest standards of quality and reliability. Each component is thoroughly tested and validated to ensure that it meets the company's strict performance criteria, and is designed to withstand the harshest operating conditions. This commitment to quality has made {Company} a trusted partner for some of the world’s leading companies in the power electronics industry, who rely on their components to power some of the most advanced electronic systems on the market."We are thrilled to introduce our new line of Ferrite Inductors to the market," said {Company} President. "We believe that these components represent a significant step forward in the world of power electronics, and we are excited to see the impact that they will have on the industry. With their high performance, compact design, and unmatched reliability, we are confident that our Ferrite Inductors will become the go-to choice for power electronics designers around the world."As the demand for smaller, lighter, and more efficient power electronics continues to grow, the importance of innovative components like Ferrite Inductors cannot be overstated. With their unique combination of properties, these components are set to revolutionize the way power electronics are designed and manufactured, and {Company} is proud to be at the forefront of this exciting new era in technology. With their commitment to quality, innovation, and customer satisfaction, {Company} is well positioned to lead the way in shaping the future of power electronics.

Customized Bare PCB Manufacturing Services for High-Quality Mcpcb Plate

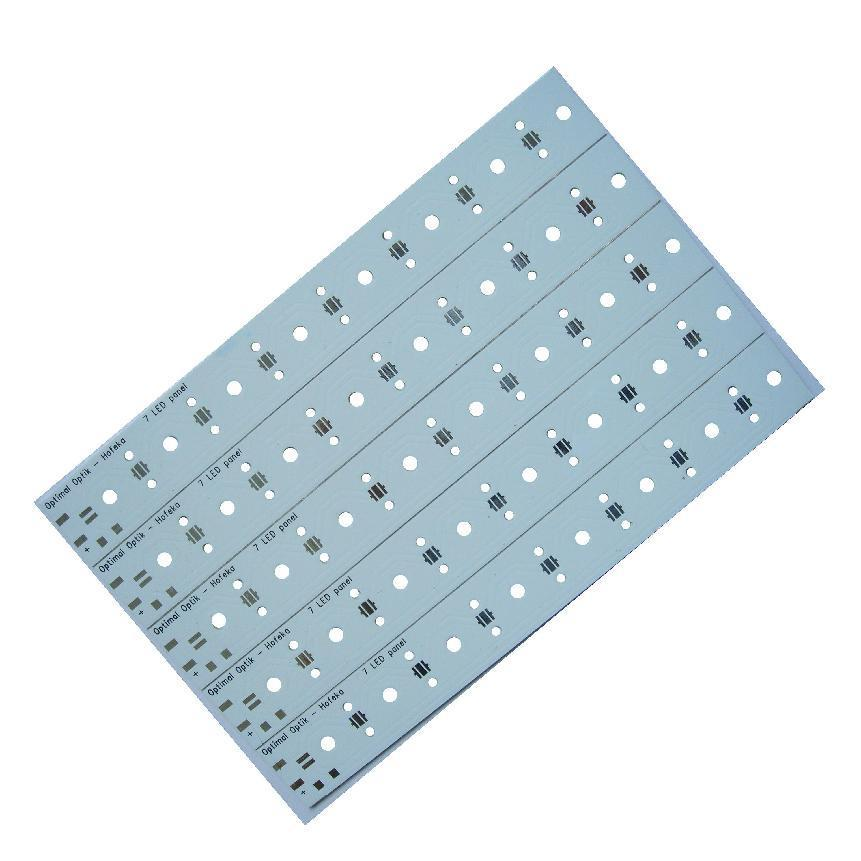

Bare Mcpcb Plate is a newly introduced product by a leading manufacturer in the PCB industry. The company has been a pioneer in the field of printed circuit boards, providing innovative and high-quality solutions to a wide range of industries. With its latest product, the Bare Mcpcb Plate, the company aims to further strengthen its position as a key player in the PCB market.The Bare Mcpcb Plate is a bare metal core printed circuit board that offers exceptional thermal performance and reliability. It is designed to meet the increasing demands of high-power LED lighting, automotive, and other electronic applications. With its superior heat dissipation capabilities, the Bare Mcpcb Plate ensures optimal performance and longevity of electronic devices, making it an ideal choice for a variety of industrial and commercial applications.The company has invested heavily in research and development to bring the Bare Mcpcb Plate to market, ensuring that it meets the highest standards of quality and performance. The product has undergone rigorous testing and validation to ensure its suitability for a wide range of applications. With its innovative design and advanced manufacturing processes, the Bare Mcpcb Plate sets a new standard for thermal management in printed circuit boards.In addition to its exceptional performance, the Bare Mcpcb Plate also offers superior flexibility and customization options. The company has the capability to tailor the product to meet specific customer requirements, offering a range of materials, thicknesses, and finishes to suit different applications. This level of customization sets the Bare Mcpcb Plate apart from other products on the market, giving customers the flexibility to create unique solutions for their specific needs.The Bare Mcpcb Plate is just one example of the company’s commitment to innovation and excellence in the PCB industry. With a strong focus on research and development, the company continues to push the boundaries of what is possible in printed circuit board technology. Its dedication to quality and performance has earned it a reputation as a trusted partner for businesses looking for cutting-edge PCB solutions.The introduction of the Bare Mcpcb Plate represents a significant milestone for the company, further solidifying its position as a leader in the PCB market. With its unmatched thermal performance, customization options, and commitment to excellence, the Bare Mcpcb Plate is set to revolutionize the way electronic devices are designed and manufactured. This new product offering is a testament to the company’s ongoing investment in technology and commitment to meeting the evolving needs of its customers.As the company continues to expand its product portfolio and push the boundaries of PCB technology, it remains focused on delivering value and performance to its customers. The Bare Mcpcb Plate is just one example of the company’s dedication to innovation and customer satisfaction, and it is poised to make a significant impact in the industry. With its cutting-edge design, exceptional thermal performance, and unmatched customization options, the Bare Mcpcb Plate is set to become a go-to solution for a wide range of electronic applications.

Future of Industry: The Impact of IoT on Manufacturing

IOT Manufacturing: Innovating the Future of TechnologyIn today's fast-paced world, the demand for connected devices and smart technology is on the rise. The Internet of Things (IOT) has become a crucial part of our daily lives, and its impact on various industries cannot be ignored. From smart homes to industrial automation, IOT has created a paradigm shift in the global technology landscape.One of the leading companies at the forefront of IOT manufacturing is {}. With a rich history of innovation and a strong commitment to excellence, {} has established itself as a pioneer in the field of IOT technology. The company's dedication to quality and customer satisfaction has earned it a reputation as a trusted partner for businesses seeking IOT solutions.{} specializes in the design and manufacturing of IOT devices, including sensors, controllers, and communication modules. These devices are used in a wide range of applications, such as smart home automation, industrial monitoring, and healthcare systems. By leveraging the power of IOT technology, {} helps businesses improve efficiency, reduce costs, and enhance overall performance.The company's state-of-the-art manufacturing facilities are equipped with the latest technology and automation processes, allowing {} to produce high-quality IOT devices at scale. With a focus on sustainability and environmental responsibility, {} is committed to reducing its carbon footprint and promoting eco-friendly practices in its manufacturing operations.{} takes pride in its team of skilled engineers and technicians who work tirelessly to develop cutting-edge IOT solutions. The company's dedication to research and development has led to numerous breakthroughs in IOT technology, enabling {} to stay ahead of the competition and meet the evolving needs of its customers.In addition to manufacturing IOT devices, {} also offers comprehensive consulting services to help businesses integrate IOT technology into their operations. The company's team of experts provides guidance on IOT strategy, implementation, and maintenance, ensuring a seamless transition to a connected environment.As the demand for IOT technology continues to grow, {} remains committed to driving innovation and pushing the boundaries of what is possible. The company's forward-thinking approach and unwavering dedication to quality have positioned it as a leader in the IOT manufacturing industry.In response to the ever-changing landscape of technology, {} continues to expand its product portfolio and explore new opportunities in the IOT space. With a focus on innovation and customer satisfaction, the company is poised to play a pivotal role in shaping the future of IOT technology.In conclusion, IOT manufacturing is revolutionizing the way we interact with technology, and companies like {} are leading the charge. With a focus on innovation, quality, and sustainability, {} is well-positioned to make a significant impact in the IOT industry for years to come. As the demand for connected devices continues to soar, {} remains steadfast in its commitment to driving progress and shaping the future of technology through IOT manufacturing.

Ultimate Guide to Integrated Inductor Technology: Benefits and Applications

Integrated Inductor Technology Revolutionizes Power ElectronicsPower electronics are an essential component of countless electronic devices, from smartphones and laptops to complex industrial machinery. These devices rely on efficient and reliable power supply for optimal performance, and as technology continues to advance, the demand for smaller, more efficient, and cost-effective power electronic components has grown. One such innovation that promises to revolutionize power electronics is the integrated inductor technology, which has been developed by a pioneering company at the forefront of the industry.The integrated inductor technology, developed by {}, is set to transform the way power electronics are designed and manufactured. Unlike traditional discrete inductors, which are separate components that need to be connected to the circuit board, integrated inductors are incorporated directly into the chip, resulting in a smaller footprint, improved efficiency, and reduced cost. This cutting-edge technology is poised to address the ongoing demand for miniaturization, higher power density, and better performance in power electronic applications.{} is a leading manufacturer of electronic components, known for its innovative solutions and high-quality products. With a strong commitment to research and development, the company has invested heavily in the advancement of power electronics technology, and the integrated inductor technology is a testament to their dedication to pushing the boundaries of what is possible in the industry.One of the key advantages of integrated inductor technology is its ability to significantly reduce the size of power electronic devices. By integrating the inductor into the chip, valuable space on the circuit board is saved, allowing for the design of smaller and more compact devices. This is particularly important in applications where space is limited, such as in mobile devices, wearables, and automotive electronics. Additionally, the smaller size of integrated inductors contributes to overall cost savings and enables the development of more streamlined and aesthetically pleasing products.Furthermore, integrated inductors offer improved performance and efficiency compared to their discrete counterparts. By reducing the length of the conductive paths and minimizing parasitic effects, integrated inductors are able to deliver faster response times, lower power losses, and higher energy efficiency. This is essential in power electronics, where every percentage point of efficiency gained can translate to significant energy and cost savings over the lifetime of a device.As technology continues to evolve, the demand for higher power density in electronic devices has become increasingly important. Integrated inductors address this demand by providing higher power density in a smaller form factor. This allows for the development of devices with increased power output without compromising on size or weight, making them ideal for applications where both power and space are at a premium.In addition to the technical benefits, the integrated inductor technology developed by {} offers a more streamlined and simplified manufacturing process. Since the inductor is integrated directly into the chip, there is no longer a need to handle and assemble separate components, which can result in improved production yields, reduced manufacturing costs, and higher overall reliability of the final product.With these advantages in mind, it is no surprise that the integrated inductor technology is generating significant interest and excitement in the power electronics industry. {} is poised to lead the way in bringing this groundbreaking technology to the market, and their commitment to innovation and excellence is set to establish them as a key player in the future of power electronics.In conclusion, the integrated inductor technology developed by {} represents a significant advancement in the field of power electronics. With its potential to revolutionize the design and manufacturing of electronic devices, this innovative technology promises to deliver smaller, more efficient, and cost-effective power electronics solutions. As the industry continues to evolve, it is clear that integrated inductors will play a pivotal role in shaping the future of power electronics, and {} is well-positioned to lead the way in this exciting new era.

Printed Circuit Assembly: Everything You Need to Know

Pca Printed Circuit Assembly, a Leading Provider of Advanced Electronics Manufacturing SolutionsPca Printed Circuit Assembly is a premier provider of advanced electronics manufacturing solutions, serving a wide range of industries including aerospace, defense, medical, automotive, and telecommunications. With a strong focus on quality, innovation, and customer satisfaction, Pca Printed Circuit Assembly has established itself as a leader in the field of printed circuit assembly and electronics manufacturing.Founded in 1985, Pca Printed Circuit Assembly has grown to become a trusted partner for some of the world's leading technology companies, providing tailored solutions to meet the most demanding requirements. The company's state-of-the-art facilities and advanced manufacturing capabilities enable them to deliver high-quality products with exceptional precision and reliability.Pca Printed Circuit Assembly offers a comprehensive range of services, including PCB assembly, box build assembly, cable and harness assembly, test and fulfillment services, and more. The company's team of highly skilled engineers and technicians work closely with customers to understand their specific needs and develop customized solutions to meet their exact requirements.With a strong commitment to quality, Pca Printed Circuit Assembly has achieved several industry certifications, including ISO 9001, AS9100, ITAR, and IPC-A-610 Class 3. These certifications reflect the company's dedication to maintaining the highest standards of excellence in every aspect of its operations.One of Pca Printed Circuit Assembly's core strengths is its ability to adapt to the rapidly evolving technology landscape. The company invests heavily in research and development to stay at the forefront of industry trends and emerging technologies. This proactive approach allows Pca Printed Circuit Assembly to offer innovative solutions that give its customers a competitive advantage in their respective markets.In addition to its focus on technology and innovation, Pca Printed Circuit Assembly places a strong emphasis on sustainability and environmental responsibility. The company is committed to minimizing its impact on the environment by implementing energy-efficient practices, reducing waste, and utilizing eco-friendly materials wherever possible.As a customer-centric organization, Pca Printed Circuit Assembly is dedicated to building long-term partnerships based on trust, integrity, and mutual success. The company's team is always responsive and attentive to customers' needs, providing expert guidance and support throughout every stage of the manufacturing process.Pca Printed Circuit Assembly's commitment to excellence has earned it a reputation for delivering consistently superior products and services. The company has received numerous accolades and awards for its achievements in electronics manufacturing, further cementing its position as an industry leader.Looking ahead, Pca Printed Circuit Assembly is poised for continued growth and success as it continues to expand its capabilities, strengthen its partnerships, and explore new opportunities for innovation and expansion. With its unwavering dedication to quality, customer satisfaction, and technological advancement, Pca Printed Circuit Assembly is well-positioned to remain at the forefront of the electronics manufacturing industry for years to come.In conclusion, Pca Printed Circuit Assembly is a dynamic and forward-thinking company that is shaping the future of electronics manufacturing. With its relentless commitment to excellence, innovation, and customer satisfaction, Pca Printed Circuit Assembly is a trusted partner for companies seeking high-quality, advanced electronics manufacturing solutions.

Innovative Flex Circuits for Superior Performance and Durability

Sculptured Flex Circuits have revolutionized the electronics industry with their innovative technology, offering flexible and lightweight circuit solutions for a wide range of applications. These advanced circuits have been developed by the renowned company {}, which has been a pioneering force in the field of flexible electronics for over three decades. With a commitment to excellence and innovation, {} has established itself as a leader in the design and manufacture of high-performance flexible circuits, catering to the diverse needs of industries such as medical devices, aerospace, automotive, consumer electronics, and more.The Sculptured Flex Circuits developed by {} offer a unique combination of flexibility, durability, and high-performance capabilities, making them an ideal choice for applications that require lightweight and compact circuit solutions. These circuits are designed to withstand the rigors of harsh environments, making them suitable for use in challenging conditions where traditional rigid circuits would not be practical. Whether it's a medical implant, a wearable device, or a mission-critical aerospace component, {}'s Sculptured Flex Circuits provide a reliable and efficient solution for diverse electronic applications.One of the key features of Sculptured Flex Circuits is their ability to conform to complex shapes and contours, allowing for seamless integration into a wide variety of products. This flexibility opens up new possibilities for product designers and engineers, enabling them to create innovative and compact electronic devices that would have been impossible with traditional rigid circuits. Additionally, the lightweight nature of these circuits makes them an excellent choice for applications where weight reduction is a critical factor, such as in aerospace and automotive components.In addition to their physical flexibility, Sculptured Flex Circuits also offer exceptional electrical performance, with low resistance and impedance characteristics that ensure reliable signal transmission. This makes them suitable for high-speed and high-frequency applications, where signal integrity is of utmost importance. Whether it's transmitting data at high speeds or handling complex analog signals, {}'s circuits deliver the performance and reliability required for demanding electronic systems.{} has invested heavily in research and development to continually improve the design and manufacturing processes of their Sculptured Flex Circuits, ensuring that they remain at the forefront of technological innovation. By leveraging advanced materials and manufacturing techniques, the company is able to produce circuits with precisely controlled geometries and electrical properties, meeting the stringent requirements of their customers across various industries.Furthermore, {}'s commitment to quality and reliability is reflected in their rigorous testing and validation processes, which ensure that every circuit meets the highest standards of performance and durability. This dedication to excellence has earned {} a reputation for delivering top-of-the-line flexible circuit solutions that consistently exceed customer expectations.As the demand for flexible and lightweight electronic solutions continues to grow across industries, {} remains at the forefront of this technological evolution, driving innovation and pushing the boundaries of what is possible with Sculptured Flex Circuits. With a track record of excellence and a forward-thinking approach to design and development, {} is poised to lead the way in shaping the future of flexible electronics, providing cutting-edge solutions for the electronic devices of tomorrow.