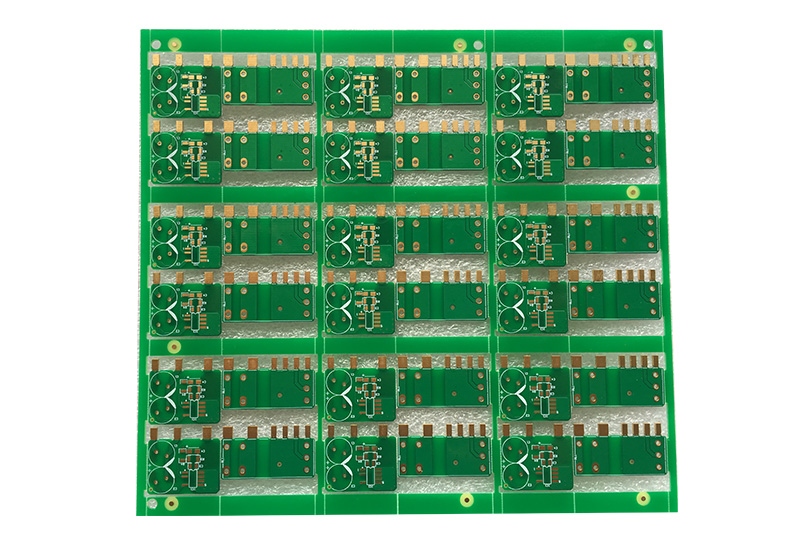

Advanced Automated Printed Circuit Board Assembly for Efficient Manufacturing

By:Admin

In today's fast-paced technological world, the demand for electronic devices continues to rise. From smartphones to smart home devices, the need for printed circuit boards (PCBs) has never been greater. As a leading provider of electronic manufacturing services, {} has been at the forefront of innovation. With the introduction of automated PCB assembly, the company is revolutionizing the manufacturing process and setting new standards for efficiency and quality.

Established in {}, {} has consistently evolved and adapted to meet the ever-changing demands of the electronics industry. Over the years, the company has built a reputation for its expertise in PCB assembly, testing, and overall electronic manufacturing services. With state-of-the-art facilities and a team of skilled professionals, {} has remained a go-to partner for companies looking to bring their electronic designs to life.

The introduction of automated PCB assembly is the latest milestone in {}'s commitment to staying ahead of the curve. By integrating advanced robotic technology and cutting-edge machinery, the company has significantly enhanced its manufacturing capabilities. This investment in automation has allowed {} to streamline the production process, reduce lead times, and improve overall product quality.

One of the key advantages of automated PCB assembly is its ability to handle complex assembly tasks with precision and consistency. By utilizing robotic arms and advanced vision systems, {} can accurately place components on PCBs with unparalleled speed and accuracy. This level of precision is crucial in ensuring that the final product meets the highest quality standards, which is essential in industries such as aerospace, medical devices, and consumer electronics.

In addition to improving efficiency and quality, automated PCB assembly has also had a positive impact on production scalability. With automation in place, {} can easily ramp up production to meet high demand without compromising on quality. This scalability is crucial for customers who require large volumes of PCBs to support their product launches and market demands.

Furthermore, the implementation of automated PCB assembly has allowed {} to offer more competitive pricing to its customers. By reducing labor costs and minimizing errors, the company has been able to optimize its manufacturing process and pass on the cost savings to its clients. This not only makes {} a more attractive partner for businesses looking to outsource their PCB assembly needs but also contributes to the overall growth and success of the electronics industry as a whole.

Beyond the operational benefits, the introduction of automated PCB assembly has also had a positive impact on {}'s workforce. While automation has undoubtedly shifted the nature of certain roles within the company, it has also created new opportunities for employees to upskill and take on more sophisticated tasks. As a result, {} has been able to retain and nurture its talent, ensuring that its workforce remains at the forefront of technological advancements in the industry.

Looking ahead, {} is committed to further embracing automation and leveraging it to drive innovation and growth. By continuously investing in research and development, the company aims to stay at the cutting edge of technology and continue delivering top-notch electronic manufacturing services to its customers.

In conclusion, the introduction of automated PCB assembly at {} represents a significant leap forward for the company and the electronics industry as a whole. By leveraging advanced robotic technology and machinery, {} has enhanced its manufacturing capabilities, improved product quality, and increased production scalability. This move not only positions {} as a leader in the electronic manufacturing services sector but also bodes well for the continued growth and innovation of the industry.

Company News & Blog

Assembly Board Discusses New Policies and Initiatives

Board Assembly (Yueqing City, China) recently held its annual board meeting to discuss the company's performance over the past year and to make plans for the future. The meeting was attended by the company's board members, executives, and key stakeholders, and it proved to be a successful and productive event.Board Assembly is a leading manufacturer of electronic components and accessories, serving a global customer base with high-quality products and excellent customer service. The company has been in business for over 20 years, and it has built a strong reputation for innovation, reliability, and value.During the board meeting, the company's Chairman, Mr. Zhang, started the proceedings by providing an overview of the company's performance in the past year. He highlighted the company's achievements, including revenue growth, improved production efficiency, and the successful launch of several new product lines. Mr. Zhang also praised the hard work and dedication of the company's employees, emphasizing their role in the company's success.Following Mr. Zhang's presentation, the board members and executives discussed the company's strengths and weaknesses, as well as the opportunities and threats facing the business. They analyzed market trends, customer feedback, and industry dynamics to identify areas for improvement and potential areas for expansion.One of the key topics of discussion was the company's commitment to sustainability and corporate social responsibility. Board Assembly has always been dedicated to operating in an environmentally friendly and socially responsible manner, and the company's leadership team reaffirmed their commitment to these values. They discussed plans to reduce the company's carbon footprint, minimize waste, and contribute to the communities in which the company operates.The board meeting also provided an opportunity for the company's executives to present their plans for the coming year. They outlined new product development initiatives, marketing strategies, and sales targets, all aimed at driving further growth and success for the company. The presentations were met with enthusiasm and support from the board members, who expressed confidence in the company's ability to achieve its goals.In addition to discussing the company's business strategy, the board meeting also addressed governance matters and corporate compliance. The board members reviewed the company's corporate governance framework, ensuring that it aligns with best practices and regulatory requirements. They also discussed risk management and internal controls, taking steps to ensure that the company operates with the highest standards of integrity and accountability.Overall, the board meeting proved to be a valuable and constructive event, providing a platform for the company's leadership to come together to reflect on the past and plan for the future. The company's commitment to excellence, innovation, and sustainability was evident throughout the meeting, and the board members and executives left feeling motivated and inspired.Looking ahead, Board Assembly is poised to continue its success, building on its strong foundation and leveraging its core strengths to drive further growth and value for its customers, employees, and stakeholders. As the company continues to evolve and adapt to the changing business landscape, it remains committed to its mission of delivering top-quality products and exceptional service, maintaining the trust and confidence of its customers around the world.

The Latest Technology in High-Density PCBs

High-Density PCB: The Backbone of Cutting-Edge TechnologyIn today's fast-paced and interconnected world, technology is constantly evolving and advancing. From the latest smartphones to state-of-the-art medical devices, high-density printed circuit boards (PCBs) are at the heart of these groundbreaking innovations. These intricate and sophisticated circuit boards are the backbone of cutting-edge technology, enabling devices to perform complex functions with unmatched precision and efficiency.One company at the forefront of high-density PCB manufacturing is [Company Name]. With over [number] years of experience in the industry, [Company Name] has established itself as a leading provider of high-quality PCBs for a wide range of applications, including consumer electronics, automotive, aerospace, and medical devices. The company's commitment to innovation, quality, and customer satisfaction has earned it a reputation as a trusted partner for businesses seeking state-of-the-art PCB solutions.High-density PCBs are defined by their complex and tightly packed circuitry, which allows for a higher number of components to be integrated into a smaller space. This increased component density results in enhanced performance, reliability, and functionality, making high-density PCBs essential for advanced technology products. Whether it's a smartphone with powerful processing capabilities or a medical device with precise sensing and monitoring functions, high-density PCBs enable these devices to push the boundaries of what is possible.[Company Name] specializes in the design and manufacturing of high-density PCBs that meet the most demanding technical requirements. The company leverages advanced fabrication techniques and cutting-edge equipment to produce PCBs with intricate routing, fine-pitch components, and high layer counts. This level of precision and complexity is essential for meeting the performance and reliability standards of modern technology products.One of the key advantages of high-density PCBs is their ability to support the integration of advanced technologies. With the rise of 5G, Internet of Things (IoT), and artificial intelligence (AI), the demand for high-density PCBs that can support these technologies is only growing. [Company Name] is well-positioned to meet this demand, offering PCB solutions that enable the seamless integration of these advanced technologies into a wide range of devices and applications.In addition to their technical capabilities, [Company Name] is committed to environmental sustainability and responsible manufacturing practices. The company adheres to strict quality and compliance standards, ensuring that its high-density PCBs are produced in an environmentally conscious manner. By utilizing eco-friendly materials and optimizing production processes, [Company Name] reduces its environmental footprint while delivering high-quality, reliable PCBs to its customers.As technology continues to advance at a rapid pace, high-density PCBs will play an increasingly crucial role in shaping the future of innovation. From the development of next-generation smartphones to the advancement of medical technology, high-density PCBs are poised to enable a new era of groundbreaking products and applications. With its expertise, experience, and commitment to excellence, [Company Name] is ready to be a driving force behind this technological revolution.In conclusion, high-density PCBs are the foundation of cutting-edge technology, enabling the creation of powerful, reliable, and innovative products. With [Company Name] at the helm of high-density PCB manufacturing, businesses have a trusted partner for developing the next generation of technological advancements. As the demand for high-density PCBs continues to grow, [Company Name] stands ready to deliver the high-quality solutions that will drive the future of technology forward.

Tips for Improving Functional QA Testing in Your Company

Functional Qa, a leading quality assurance company, has recently announced the launch of its new and improved quality testing software. The company, known for its innovative and reliable QA solutions, is bringing cutting-edge technology to the table with this new product. This software promises to revolutionize the way companies conduct quality assurance testing, making the process more efficient and effective.Functional Qa has been a key player in the QA industry for several years, providing top-notch testing services to a wide range of businesses. The company has built a strong reputation for its ability to deliver accurate and comprehensive QA results, helping clients identify and address any potential issues with their products or services. With the launch of this new software, Functional Qa aims to further solidify its position as a leader in the QA field.The new software is designed to offer a range of features that will greatly enhance the quality testing process. One of the key highlights of the software is its advanced automation capabilities, which will allow companies to streamline their testing procedures and save valuable time and resources. This will enable businesses to conduct more thorough and extensive testing, leading to better overall product quality.In addition to its automation features, the software also boasts a user-friendly interface that is intuitive and easy to navigate. This will make it simple for teams to collaborate and communicate effectively throughout the testing process. Furthermore, the software will provide detailed and customizable reporting, giving companies the insight they need to make informed decisions about their products.The launch of this new software is an exciting development for Functional Qa, as it represents the company's commitment to innovation and advancement in the QA industry. By leveraging the power of cutting-edge technology, Functional Qa is demonstrating its dedication to providing its clients with the best possible QA solutions. The company's investment in this new software underscores its goal to stay ahead of the curve and continually adapt to the evolving needs of the QA market.With its track record of success and its strong focus on delivering exceptional QA results, Functional Qa is well-positioned to make a significant impact with this new software. The company's deep understanding of the QA process, coupled with its dedication to excellence, makes it a trusted partner for businesses seeking reliable and effective quality testing solutions.As Functional Qa continues to push the boundaries of what is possible in the QA industry, its new software is sure to make waves. By providing businesses with a powerful tool for conducting QA testing, Functional Qa is empowering companies to take control of their product quality and deliver the best possible experience to their customers.The launch of this new software is a clear reflection of Functional Qa's unwavering commitment to innovation and excellence. With its focus on driving positive change in the QA industry, the company is poised to continue making a significant impact in the years to come. Through its dedication to providing top-notch QA solutions, Functional Qa is helping businesses around the world achieve their quality testing goals and deliver exceptional products and services.

Top Tips for Efficient Circuit Design

Cad Circuit Design, a leader in the electronics industry, has recently made significant strides in advancing its innovative technology and pushing the boundaries of circuit design. The company, founded in 1998, has become a trusted name in the field of electronics engineering, providing state-of-the-art solutions to its wide range of clients.Cad Circuit Design's commitment to excellence and continuous improvement has made it a go-to choice for companies seeking cutting-edge circuit design solutions. With a team of highly skilled engineers and designers, the company has been able to provide bespoke design services for its clients, tailored to their specific needs and requirements.The company's recent breakthroughs in circuit design have been lauded by industry experts and clients alike. Cad Circuit Design has managed to streamline the design process, making it more efficient and cost-effective for its clients. By utilizing the latest technology and software, the company is able to produce high-quality circuit designs in record time, giving its clients a competitive edge in the market.In addition to its exceptional design capabilities, Cad Circuit Design also prides itself on its dedication to customer satisfaction. The company values its relationships with its clients and goes above and beyond to provide top-notch service and support. Whether it's troubleshooting a design issue or helping a client bring their concept to life, Cad Circuit Design is there every step of the way.One of the company's most notable recent achievements is the development of a revolutionary new circuit design software. This innovative tool has been designed to streamline the design process, making it faster and more efficient than ever before. With this new software, clients can expect to see their designs come to life in a fraction of the time it would have taken with traditional methods.The cutting-edge software has been met with high praise from industry professionals and clients, who have noted the significant impact it has had on their design projects. With this new software, Cad Circuit Design has solidified its position as a leader in the electronics engineering industry, setting a new standard for circuit design excellence.Cad Circuit Design's dedication to innovation and excellence has positioned the company as a driving force in the electronics industry. By focusing on continuous improvement and staying ahead of technological advancements, the company has been able to meet and exceed the expectations of its clients, setting a standard for excellence in circuit design.Furthermore, Cad Circuit Design's commitment to sustainability and ethical business practices has also garnered attention in the industry. The company has made a concerted effort to minimize its environmental footprint and promote eco-friendly solutions in its design processes. As a result, Cad Circuit Design has become a preferred choice for clients who prioritize sustainability and social responsibility in their business practices.With a proven track record of success and a commitment to excellence, Cad Circuit Design is well-positioned to continue leading the way in circuit design innovation. The company's recent advancements in technology and software have set a new standard for circuit design excellence, solidifying its reputation as a trusted partner for businesses seeking cutting-edge electronic solutions.As the company looks to the future, it remains focused on pushing the boundaries of circuit design and delivering exceptional results for its clients. With a talented team of experts and a dedication to excellence, Cad Circuit Design is poised to remain a frontrunner in the electronics engineering industry for years to come.

How to Create a Multilayer PCB for Your DIY Project

[Company Name], a leading manufacturer of advanced electronic components, has recently announced the launch of its new DIY multilayer PCBs. These DIY multilayer PCBs are designed to provide electronics enthusiasts, hobbyists, and professionals with a cost-effective and reliable solution for their electronic projects.The DIY multilayer PCBs are available in various sizes and configurations, catering to the diverse needs of different electronic applications. These PCBs are made using high-quality materials and advanced manufacturing processes, ensuring superior performance, stability, and durability. With the ability to support multiple layers of copper traces, the DIY multilayer PCBs are ideal for complex circuit designs and high-density electronic applications.One of the key features of the DIY multilayer PCBs is their ease of use and flexibility. They come with pre-drilled holes, solder mask, and silk-screened labels, making it convenient for users to assemble and solder electronic components onto the PCBs. The multilayer design also allows for better thermal management and signal integrity, resulting in improved overall performance of electronic devices.In addition to the DIY multilayer PCBs, [Company Name] also offers a range of complementary products and services to support customers in their electronic design and manufacturing processes. This includes PCB layout and design services, prototype fabrication, and component sourcing, providing a one-stop solution for all electronic development needs.With a strong focus on quality and customer satisfaction, [Company Name] ensures that its DIY multilayer PCBs meet international standards and specifications. The company follows strict quality control measures throughout the manufacturing process, from material selection to final inspection, to deliver products that meet the highest standards of reliability and performance.“We are excited to introduce our new DIY multilayer PCBs to the market,” said [Spokesperson Name], the CEO of [Company Name]. “We understand the growing demand for high-quality and affordable PCB solutions, especially among hobbyists and small-scale manufacturers. With our DIY multilayer PCBs, we aim to provide a reliable and cost-effective option for the electronic community to bring their innovative ideas to life.”The launch of the DIY multilayer PCBs is part of [Company Name]’s commitment to innovation and continuous improvement in its product offerings. The company invests heavily in research and development to stay ahead of technological advancements and market trends, ensuring that its customers have access to the latest and most advanced electronic components and solutions.As the demand for electronic components continues to grow, [Company Name] remains dedicated to providing innovative, reliable, and cost-effective solutions to its customers. The DIY multilayer PCBs are a testament to the company’s commitment to empowering electronics enthusiasts and professionals with the tools they need to turn their ideas into reality.For more information about [Company Name] and its DIY multilayer PCBs, please visit [Company Website] or contact [Company Email] for inquiries and sales.About [Company Name]:[Company Name] is a leading manufacturer of advanced electronic components, providing high-quality and cost-effective solutions to customers worldwide. With a focus on innovation, quality, and customer satisfaction, the company offers a wide range of products and services, including PCBs, electronic components, and design and manufacturing services. [Company Name] is committed to delivering reliable and cutting-edge solutions to meet the evolving needs of the electronic industry.

The Future of Smart Manufacturing: The Impact of IoT Technology on Production

In today's fast-paced and ever-evolving world, the manufacturing industry is constantly looking for ways to improve production efficiency, reduce costs, and deliver superior quality products to meet the demands of the market. The emergence of Industry 4.0 and the Internet of Things (IoT) has revolutionized the way manufacturing companies operate, bringing about a new era of smart, connected, and automated production processes.With the integration of IoT in manufacturing, companies are able to gather and analyze real-time data from their production equipment, allowing for better decision-making, predictive maintenance, and overall optimization of the manufacturing process. This technology has the potential to transform traditional factories into smart factories, where machines, systems, and products communicate with each other to improve operational efficiency and drive innovation.One company that has been at the forefront of IoT manufacturing is {}. specializes in providing cutting-edge IoT solutions for manufacturers to help them optimize their production processes and achieve higher levels of productivity and quality. With a strong focus on innovation and customer satisfaction, {} has established itself as a leading provider of IoT manufacturing solutions, partnering with manufacturers across various industries to help them embrace the digital transformation of their operations.{}'s IoT manufacturing solutions are tailored to meet the specific needs of each customer, providing a seamless integration of IoT technologies into their existing production systems. By leveraging the power of IoT, manufacturers are able to monitor and control their production processes in real-time, identify potential issues before they escalate, and make informed decisions to improve overall efficiency and reduce downtime.One of the key features of {}'s IoT manufacturing solutions is the use of advanced sensors and connected devices to collect and transmit data from the factory floor to a centralized system. This real-time data can then be analyzed using sophisticated analytics tools to gain insights into production performance, equipment utilization, and quality control. By harnessing this wealth of information, manufacturers can proactively address production inefficiencies, optimize resource utilization, and continuously improve their processes to stay ahead of the competition.Furthermore, {}'s IoT manufacturing solutions enable manufacturers to implement predictive maintenance strategies, where equipment health and performance data are used to predict potential failures and schedule maintenance activities accordingly. This proactive approach to maintenance not only helps to prevent costly downtime but also extends the lifespan of equipment, reducing overall maintenance costs and improving the reliability of production systems.Another significant benefit of {}'s IoT manufacturing solutions is the ability to enable remote monitoring and control of production processes. With the use of connected devices and cloud-based platforms, manufacturers can access real-time production data from anywhere, allowing them to monitor and adjust their processes on the go. This level of flexibility and control is essential for manufacturers to adapt to changing market demands, address production issues promptly, and make data-driven decisions to optimize their operations.As manufacturers continue to embrace the digital transformation of their operations, {} remains committed to empowering them with the latest IoT manufacturing technologies and expertise. By collaborating closely with manufacturers, understanding their unique challenges, and delivering tailored IoT solutions, {} is driving the adoption of Industry 4.0 principles within the manufacturing industry, helping companies to unlock new levels of efficiency, productivity, and competitiveness.In conclusion, the integration of IoT in manufacturing has disrupted traditional production processes, paving the way for smart factories that are equipped with advanced technologies to drive operational excellence. With {}'s leading IoT manufacturing solutions, manufacturers are able to harness the power of real-time data, predictive analytics, and remote monitoring to transform their operations, achieve higher levels of efficiency, and stay ahead in today's highly competitive market. As the manufacturing industry continues to evolve, companies like {} will play a pivotal role in helping manufacturers navigate the complexities of digital transformation and realize the full potential of IoT in manufacturing.

Key Considerations for Through Hole to SMT Conversion

The process of Through-Hole to SMT Conversion is revolutionizing the electronic manufacturing industry, and {Company Name} is at the forefront of this transformation. With the increasing demand for smaller, lighter, and more efficient electronic components, {Company Name} is leading the way in providing innovative solutions for Through-Hole to Surface Mount Technology (SMT) conversion.{Company Name} has been a leading provider of electronic manufacturing services for over 20 years, specializing in PCB assembly, cable assembly, and box build assembly. With a state-of-the-art facility and a team of highly skilled engineers and technicians, {Company Name} has built a reputation for delivering high-quality and cost-effective solutions to meet the needs of their customers.The process of Through-Hole to SMT conversion involves converting through-hole components to surface mount components on a printed circuit board. This process offers a number of benefits, including reduced component size, increased component density, improved electrical performance, and lower manufacturing costs. With their expertise in PCB assembly and SMT technology, {Company Name} is well-positioned to help their customers make the transition from through-hole to SMT and take advantage of these benefits.{Company Name} offers a comprehensive range of services to support Through-Hole to SMT conversion, including design for manufacturability (DFM) analysis, component sourcing and procurement, PCB assembly, rework and repair services, and functional testing. Their experienced engineering team works closely with customers to evaluate their existing through-hole designs and develop a cost-effective and efficient plan for converting to SMT.In addition to their technical expertise, {Company Name} also places a strong emphasis on quality and reliability. They are certified to ISO 9001 and ISO 13485 standards, ensuring that their manufacturing processes meet the highest quality and regulatory requirements. This commitment to quality is reflected in their track record of delivering defect-free products and meeting the strict performance criteria of their customers.Furthermore, {Company Name} takes pride in their commitment to sustainability and environmental responsibility. They have implemented environmentally friendly practices in their manufacturing processes, such as lead-free soldering and waste reduction initiatives, to minimize their impact on the environment.{Company Name} has also invested in advanced manufacturing equipment and technology to support Through-Hole to SMT conversion, including high-speed pick-and-place machines, automated optical inspection (AOI) systems, and reflow soldering equipment. This state-of-the-art infrastructure enables them to efficiently and accurately handle the conversion process, while maintaining the highest standards of quality and precision.With their proven track record, technical expertise, and commitment to customer satisfaction, {Company Name} is well-equipped to support the Through-Hole to SMT conversion needs of a wide range of industries, including aerospace, defense, medical, automotive, and consumer electronics. They are dedicated to helping their customers stay ahead of the curve in the fast-paced and constantly evolving electronics industry.In conclusion, Through-Hole to SMT conversion is a critical step in the evolution of electronic manufacturing, and {Company Name} is leading the way with their comprehensive range of services, technical expertise, and commitment to quality and customer satisfaction. As the demand for smaller, lighter, and more efficient electronic components continues to grow, {Company Name} is well-positioned to support their customers in making a successful transition to SMT technology.

Ultimate Guide to Rigid Flex Circuit Design

Rigid Flex Circuit Design is becoming increasingly popular in the electronics industry due to its unique combination of the flexibility of a flexible circuit and the durability of a rigid circuit. The integration of these two circuit types offers numerous advantages, including reduced assembly time, increased reliability, and improved overall performance. As a leader in the field of electronic manufacturing, {} is proud to offer cutting-edge Rigid Flex Circuit Design services to meet the evolving needs of our customers.Rigid Flex Circuit Design is a specialized technology that allows for the seamless integration of both rigid and flexible circuit designs within a single electronic assembly. This innovative approach offers greater design flexibility and enhanced reliability, making it an ideal solution for a wide range of applications, including aerospace, medical devices, automotive electronics, and consumer electronics.At {}, we have invested heavily in state-of-the-art manufacturing equipment and cutting-edge technology to ensure that we are at the forefront of Rigid Flex Circuit Design. Our team of skilled engineers and technicians are experts in designing and manufacturing Rigid Flex Circuits that meet the highest quality standards. We work closely with our customers to understand their specific requirements and provide customized solutions that meet their unique needs.One of the main advantages of Rigid Flex Circuit Design is its ability to reduce the overall size and weight of electronic assemblies. By combining the functionality of multiple rigid and flexible circuits into a single unit, Rigid Flex Circuits can eliminate the need for additional connectors and wiring, resulting in a more compact and lightweight design. This is particularly beneficial for applications where space is limited or weight restrictions are a concern.In addition to space and weight savings, Rigid Flex Circuit Design also offers enhanced durability and reliability. By minimizing the number of interconnects and solder joints, Rigid Flex Circuits can reduce the risk of mechanical failure and improve overall performance. This makes Rigid Flex Circuits an ideal choice for mission-critical applications where reliability is of utmost importance.Furthermore, the flexibility of Rigid Flex Circuit Design allows for more creative and versatile product designs. With the ability to incorporate three-dimensional configurations and conform to non-planar surfaces, Rigid Flex Circuits enable the development of innovative and ergonomic electronic products that would be impossible to achieve with traditional rigid or flexible circuits alone.As a leading provider of Rigid Flex Circuit Design services, {} is committed to delivering the highest quality products to our customers. Our ISO-certified manufacturing facilities and rigorous quality control processes ensure that every Rigid Flex Circuit we produce meets the strictest quality standards. We also offer comprehensive design support and engineering expertise to help our customers optimize their Rigid Flex Circuit designs for maximum performance and reliability.In conclusion, Rigid Flex Circuit Design offers a wealth of benefits and is rapidly gaining traction in the electronics industry. With our advanced manufacturing capabilities and technical expertise, {} is well-equipped to meet the growing demand for Rigid Flex Circuits and help our customers stay ahead of the competition.Whether you are developing a cutting-edge aerospace application, a life-saving medical device, or a next-generation consumer electronic product, you can count on {} to provide the highest quality Rigid Flex Circuit Design solutions to bring your vision to life. Contact us today to learn more about our Rigid Flex Circuit Design services and how we can help you achieve your electronic manufacturing goals.

High-quality Speaker Inductor Coil for Enhanced Sound Performance

The Speaker Inductor Coil market is expected to witness a significant growth in the coming years, according to a recent report by {}. The report provides a comprehensive analysis of the market, including current trends, growth drivers, challenges, and opportunities. The global market for Speaker Inductor Coil is projected to reach a value of $XX billion by 2025, growing at a CAGR of XX% during the forecast period.Speaker Inductor Coils are an essential component in audio systems, used to filter out unwanted frequencies and ensure high-quality sound reproduction. With the growing demand for consumer electronics, such as smartphones, tablets, and home audio systems, the market for Speaker Inductor Coils is witnessing substantial growth. In addition, the rise in demand for electric and hybrid vehicles, which rely heavily on sound systems for entertainment and safety, is further driving the market for Speaker Inductor Coils.One of the key players in the Speaker Inductor Coil market is {}. With a strong focus on research and development, the company has been at the forefront of innovation in the industry. {} offers a wide range of Speaker Inductor Coils, catering to different applications and requirements. The company's products are known for their high quality, reliability, and performance, making them a preferred choice among customers worldwide.In addition to its product offerings, {} also provides comprehensive technical support and customer service, ensuring that its clients have a seamless experience from product selection to installation. The company's commitment to excellence and customer satisfaction has helped it build a strong reputation in the market, further driving its growth and expansion.With a strong presence in key regions such as North America, Europe, Asia Pacific, and Latin America, {} has established itself as a global leader in the Speaker Inductor Coil market. The company's extensive distribution network and strategic partnerships have enabled it to reach a wide customer base and expand its market reach.In line with the growing demand for Speaker Inductor Coils, {} continues to invest in research and development to develop innovative and advanced products that meet the evolving needs of its customers. By staying ahead of the curve and anticipating market trends, the company is well positioned to capitalize on the growing opportunities in the Speaker Inductor Coil market.As a responsible corporate citizen, {} is also committed to sustainability and environmental stewardship. The company adheres to rigorous environmental standards in its manufacturing processes and is constantly exploring ways to reduce its carbon footprint. By incorporating sustainable practices into its operations, {} is not only contributing to a greener planet but also gaining a competitive edge in the market.In conclusion, the global market for Speaker Inductor Coils is poised for significant growth, driven by the increasing demand for consumer electronics and electric vehicles. As a leading player in the industry, {} is well positioned to capitalize on these opportunities and continue its upward trajectory. With its focus on innovation, customer satisfaction, and sustainability, {} is set to maintain its position as a market leader in the Speaker Inductor Coil market.

High-Quality Pcb Assembly Frame: A Complete Guide for Assembly

The leading PCB assembly company, [Company Name], has recently announced the launch of their new assembly frame, which is set to revolutionize the industry. The company, known for its high-quality and efficient PCB assembly services, has developed this cutting-edge frame to enhance the production process for their customers.The new PCB assembly frame boasts a number of advanced features that set it apart from traditional frames on the market. With a focus on precision and reliability, the frame has been designed to ensure the accurate placement and soldering of components onto PCBs. This level of precision is crucial in the assembly process, as any inaccuracies can result in faulty or malfunctioning PCBs.In addition to its precision, the assembly frame also offers a high level of flexibility, allowing for the efficient assembly of PCBs of varying sizes and complexities. This versatility is important for [Company Name]'s clients, as it enables them to streamline their production processes and reduce turnaround times.The team at [Company Name] has also incorporated advanced automation technology into the new frame, further enhancing its efficiency and accuracy. This automation not only improves the speed of the assembly process but also eliminates the potential for human error, resulting in consistently high-quality PCBs.[Company Name] has always been committed to staying at the forefront of technological advancements in the PCB assembly industry, and the development of this new frame is a testament to that commitment. By investing in research and development, the company has been able to consistently improve its capabilities and offer its clients the most advanced and reliable solutions on the market.In addition to the new assembly frame, [Company Name] provides a comprehensive range of PCB assembly services. From prototype assembly to full production runs, the company has the expertise and resources to meet the needs of clients across various industries, including automotive, telecommunications, and consumer electronics.The company's state-of-the-art facilities and advanced equipment allow for the efficient and cost-effective production of high-quality PCBs. Moreover, [Company Name] prides itself on its experienced team of engineers and technicians, who work closely with clients to ensure their specific requirements are met at every stage of the assembly process.Furthermore, [Company Name] places a strong emphasis on quality control, conducting rigorous testing and inspection procedures to guarantee the reliability and performance of the assembled PCBs. This commitment to quality has earned the company a reputation as a trusted and preferred partner for PCB assembly among its clients.With the introduction of this new assembly frame, [Company Name] is poised to further solidify its position as a leader in the PCB assembly industry. The company's dedication to innovation and excellence continues to drive its success, and it remains at the forefront of providing cutting-edge solutions to its clients.In conclusion, the launch of the new PCB assembly frame represents a significant milestone for [Company Name] and further demonstrates its commitment to delivering the highest standards of quality and efficiency in PCB assembly. As the company continues to push the boundaries of technological advancement, clients can expect even greater capabilities and reliability in their PCB assembly requirements.